Are you a business owner seeking innovative ways to cut costs, streamline operations, and enhance overall efficiency? One powerful strategy that businesses can leverage to achieve these goals is contract manufacturing. This business model offers numerous advantages that directly contribute to reduced costs across various dimensions.

The Top 10 Strategic Advantages of Contract Manufacturing

1. Economies of Scale in Manufacturing Processes

Economies of scale refer to the cost advantages gained by increasing the scale of production, resulting in lower average costs per unit as output levels rise. Contract manufacturers often operate on a larger scale, allowing them to spread fixed costs over a higher volume of production. By partnering with a reputable contract manufacturer, businesses can tap into economies of scale, a key driver of cost reduction.

Key benefits

- Reduced per-unit costs through larger production volumes.

- Efficient utilization of resources spreads fixed costs effectively.

- Competitive pricing in the market due to scale-driven cost efficiencies.

2. Direct and Indirect Cost Savings

Contract manufacturing enables companies to offload direct labor costs, operating costs, and variable costs to the experienced contract manufacturer. Moreover, indirect costs like maintenance, overhead, and inventory expenses can be significantly minimized through the efficient management of resources and facilities by the contract manufacturing partner.

Key benefits

- Offloading direct costs like labor, operating, and variable costs.

- Minimization of indirect costs, including maintenance, overhead, and inventory expenses.

- Efficient resource management results in substantial cost reductions.

3. Optimal Resource Allocation and Focus on Core Competencies

Outsourcing non-core processes to a contract manufacturer allows businesses to concentrate on their core competencies. The contract manufacturer’s expertise in manufacturing processes, engineering services, and assembly operations ensures optimal resource allocation, eliminating the need for businesses to invest in expensive machinery and extensive employee training.

Key benefits

- Concentration on core competencies without investing in extensive training or machinery.

- Elimination of the need for businesses to maintain expensive production floors.

- Access to specialized engineering services without the associated costs.

4. Quality Control and Assurance

Reputable contract manufacturers uphold rigorous quality standards throughout the production process. This commitment to quality, coupled with their established relationships with suppliers and continuous improvement initiatives, results in high-quality products. Businesses can benefit from reduced error correction costs, improved customer satisfaction, and enhanced brand reputation.

Key benefits

- Rigorous adherence to quality standards throughout the production process.

- Established relationships with suppliers that ensure access to quality materials.

- Continuous improvement initiatives contribute to a mature quality system.

5. Risk Mitigation and Flexibility

The inherent risks associated with manufacturing, such as fluctuations in demand and human errors, are mitigated through the outsourcing model. Contract manufacturers offer flexibility in operations, adapting to changes in production schedules and demand. This not only reduces operational risks but also allows businesses to make informed decisions based on accurate demand forecasting.

Key benefits

- Mitigation of operational risks associated with demand fluctuations.

- Flexibility in adapting to changes in production schedules and market demands.

- Informed decision-making based on accurate demand forecasting.

6. Cost-Effective Procurement and Bulk Purchasing Discounts

Contract manufacturers often have established relationships with suppliers, enabling them to negotiate favorable prices for raw materials. Bulk purchasing discounts, along with efficient procurement processes, contribute to significant cost savings. This cost-effectiveness extends to energy consumption, with some contract manufacturers incorporating renewable energy sources into their operations.

Key benefits

- Negotiation of favorable prices for raw materials through established supplier relationships.

- Realization of cost savings through efficient procurement processes.

- Integration of renewable energy sources for further cost-effectiveness.

7. Strategic Relationships and Continuous Improvement

Long-term, stable contracts with contract manufacturers foster beneficial relationships. This collaboration allows for continuous improvement initiatives, where both parties work together to enhance operational efficiency, reduce production costs, and stay ahead of market trends.

Key benefits

- Development of long-term, stable contracts that foster beneficial relationships.

- Collaboration on continuous improvement initiatives to enhance operational efficiency.

- Proactive adjustment to market trends for sustained competitiveness.

8. Advanced Analytics and Predictive Maintenance

Modern contract manufacturers leverage advanced analytics to optimize production levels, prevent disruptions, and minimize downtime. Predictive maintenance practices ensure that manufacturing equipment operates at peak efficiency, reducing maintenance costs and enhancing overall productivity.

Key benefits

- Optimization of production levels through data-driven analytics.

- Prevention of disruptions and reduced downtime through predictive maintenance.

- Lower maintenance costs and enhanced overall productivity.

9. Rapid Product Development and Time-to-Market Efficiency

Contract manufacturing accelerates the product development process by leveraging the contract manufacturer’s expertise and efficient production capabilities. With streamlined operations, businesses can bring products to market faster, reducing time-to-market. This agility is particularly advantageous in industries where being the first to introduce new products or respond to market trends is a key competitive factor.

Key benefits

- Acceleration of the product development process.

- Faster time-to-market due to streamlined production capabilities.

- Agility in responding to market trends and gaining a competitive edge.

10. Cost-Effective Scalability and Production Flexibility

Contract manufacturing provides a scalable solution for businesses, allowing them to adjust production levels based on demand fluctuations without incurring substantial upfront costs. The flexibility to scale production up or down efficiently ensures optimal resource utilization, prevents excess capacity expenses, and positions businesses to adapt swiftly to changes in the market, ultimately reducing financial risks.

Key benefits

- Scalable production levels without substantial upfront costs.

- Efficient adjustment to demand fluctuations to prevent excess capacity expenses.

- Swift adaptation to changes in the market for reduced financial risks.

How to find a contract manufacturer

Embracing the Future of Manufacturing Operations

Contract manufacturing offers businesses a strategic advantage in the highly competitive market. By focusing on cost reduction, quality assurance, and operational efficiency, companies can position themselves for long-term success. As the business landscape continues to evolve, the flexibility, cost-effectiveness, and innovation provided by contract manufacturing will play an increasingly pivotal role in shaping the future of manufacturing.

Contract Manufacturing Services

Alpha Contract Manufacturing is a distinguished industry leader providing unparalleled solutions in industrial contract manufacturing. With a commitment to excellence and a focus on client satisfaction, we proudly stand at the forefront of the manufacturing landscape. Our turnkey solutions, fortified by cutting-edge technology and a dedicated team of experts, ensure efficient and cost-effective results for projects of any scale.

Why Choose ACMG for Your Contract Manufacturing Needs?

- Reliable Outsourcing Services: Our outsourcing services are designed to be reliable, efficient, and fully aligned with the needs of modern manufacturers. We serve hundreds of active customers and manufacture thousands of parts and finished products daily.

- Expertise and Commitment: Our team of experts brings years of industry experience, ensuring top-notch service delivery across all our offerings. We are committed to using state-of-the-art equipment and facilities to meet the highest quality standards in every project.

- Turnkey Industrial Solutions: We offer turnkey solutions across all services, ensuring a seamless experience from design to delivery. Our customer-centric approach prioritizes excellent service and friendly interactions at every step.

Our Diverse Contract Manufacturing Services

- Industrial Painting: We provide turnkey industrial painting services, understanding the critical role coating specifications play in the quality of the final product.

- Industrial Automation: Optimize your factory’s production processes and performance with our cutting-edge automation and robotization services.

- Wood Processing: We handle all stages of wood processing, ensuring quality for both small and large-volume requirements.

- Rubber Processing: Reduce manufacturing time for molded rubber parts with our in-house mold manufacturing, offering a seamless turnkey operation.

- Composite & Plastic Manufacturing: We’re ready to handle your complex design and manufacturing projects in the field of composites and plastics.

- Electromechanics: From wiring to fully assembled panels, our engineering team assists and advises on electromechanical projects.

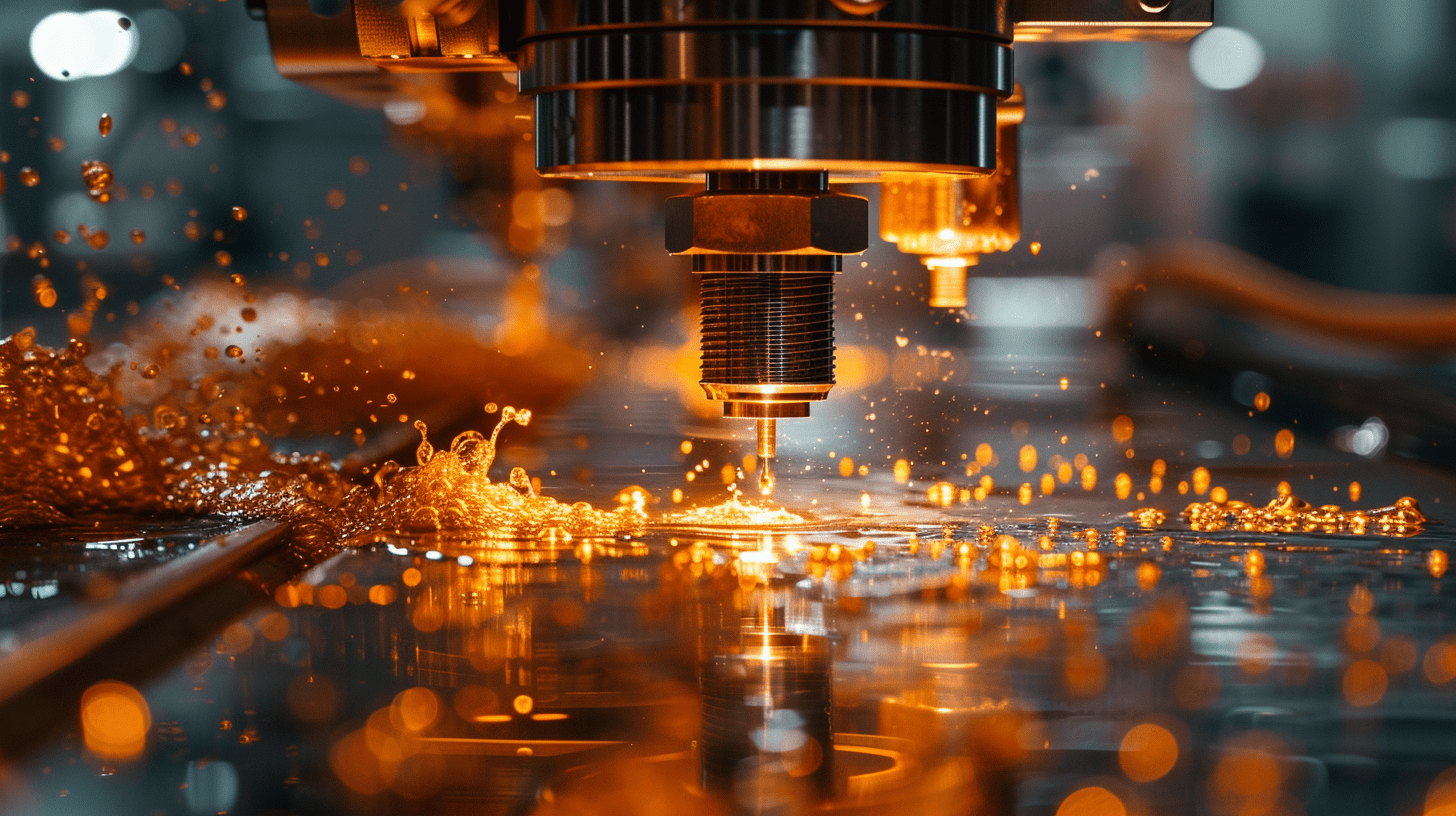

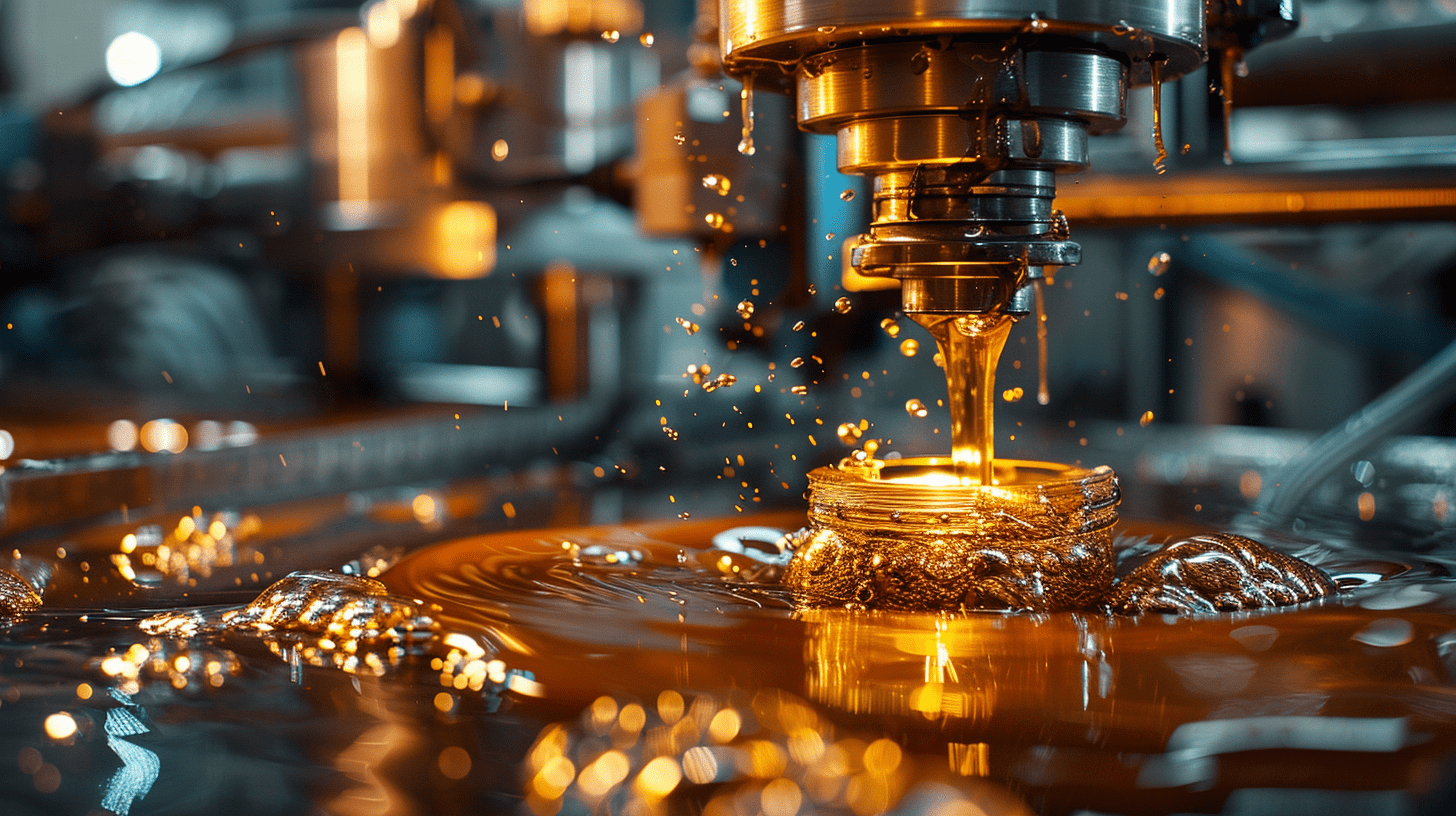

- Metal Processing: We provide turnkey solutions with a combination of skills necessary for meeting diverse metal processing needs.

- Industrial Welding: Rely on our expertise in complex welding processes, ensuring a high-quality turnkey experience for projects of any scale.

- Plastics Manufacturing: We are committed to being the perfect plastic manufacturing partner, delivering high-quality plastic products using state-of-the-art equipment.

- Laser Cut & Water Jet Cut: We excel in precision cutting services, offering both laser cutting and water jet cutting for various materials.

- Powder Coating: Our powder coating service ensures a perfect finish for metal parts, using specialized equipment and skilled specialists.

SEO GLOSSARY›