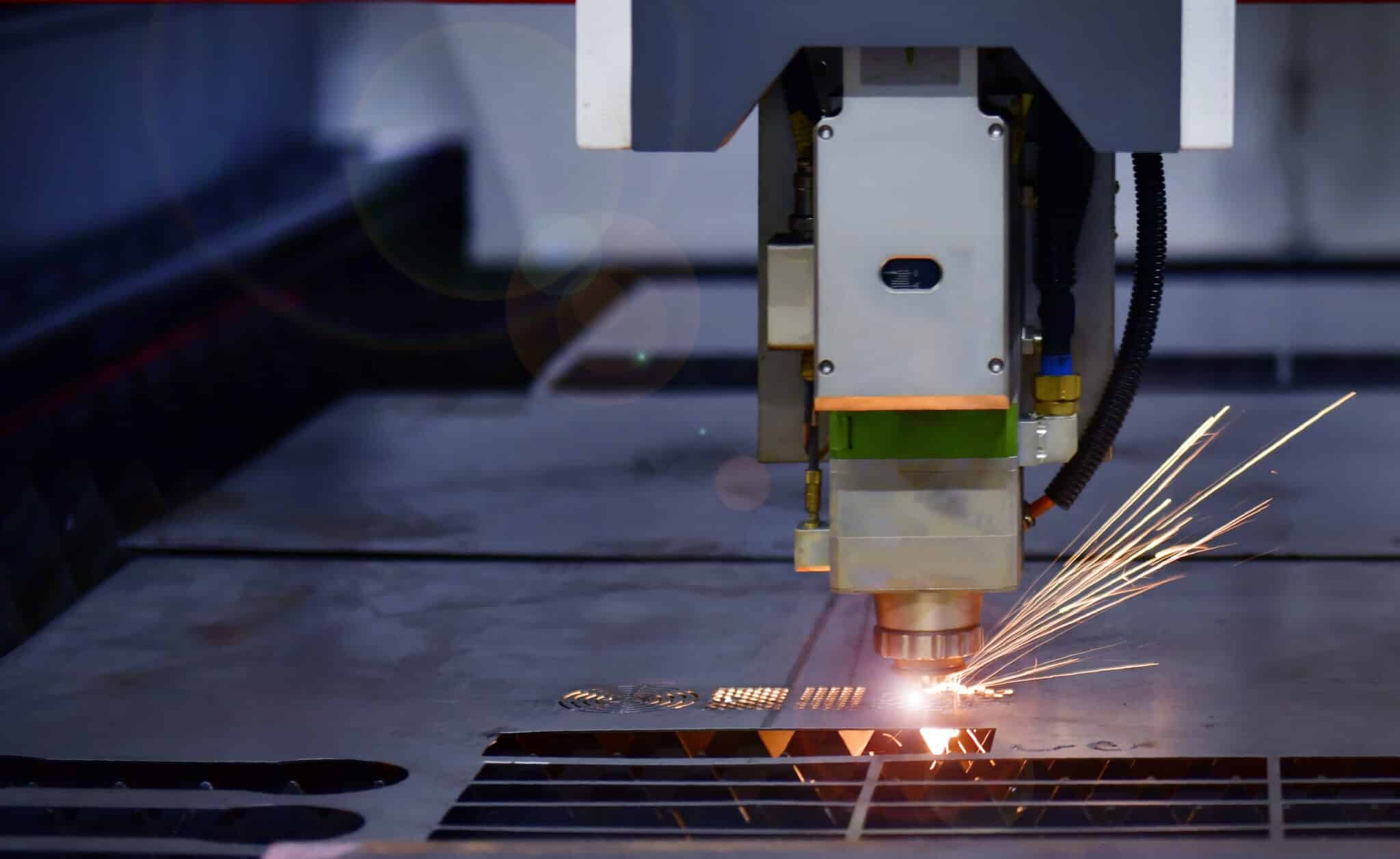

ACMG is the leader in providing laser cutting services using high-speed laser cutters, processing a variety of materials including common types like steel and aluminum, for businesses. With our state-of-the-art laser systems, solid-state lasers and laser power, we ensure superior quality services and design expertise.

Alpha’s laser cutting process, as an accurate and swift method, facilitates the precise processing of a wide range of materials, resulting in minimal waste. It opens up a vast range of design possibilities with its capabilities to cut complex shapes and layers, helping your business save resources and time.

At ACMG, we take pride in our comprehensive laser cutting services. Our expert team, equipped with the latest laser cutting technology, has vast experience in producing designs on a variety of materials using our laser machines. We’re committed to helping businesses achieve success.

Our laser cutting capabilities extend to a broad range of metals, including the toughest alloys of steel and stainless steel. Whether for automotive tooling or aerospace hardware fabrication, our machines deliver clean, precise cuts and laser engraving options with minimal tolerances.

Aluminum’s lightweight properties combined with our advanced laser cutters and CNC technology make it an ideal choice for everything from rapid prototyping to final product manufacturing. We ensure high-quality cuts, critical for the production of components in industries where weight and precision matter.

Copper and its alloys, including brass, benefit from our precision laser cutting and waterjet cutting services, offering unparalleled accuracy for electrically conductive components. Our expertise extends to creating pieces with complex geometries, all while maintaining the integrity of the metal sheet.

Our machines, equipped with CO2 and fiber lasers, are adept at handling a variety of materials, including plexiglass, MDF, and acrylic, alongside metal sheet fabrication. We supports a wide range of applications, from laser-cut prototypes to parts requiring precise tolerances, deburring, and finishing processes.

Take advantage of our extensive experience in laser and waterjet cutting, where precision engineering meets the art of fabrication. Our team’s proficiency ensures that your projects, from sheet metal to acrylic and plastics, are executed with precision, meeting stringent aerospace and automotive standards.

Achieve unparalleled consistency and quality in your metal sheet projects. Our laser cutting technology, equipped with numerically controlled programming, delivers exact cuts, detailed engraving, and intricate markings across a wide range of materials and thicknesses, maintaining strict tolerances that are essential for high-quality manufacturing.

Our advanced laser cutters and plasma cutters are capable of transforming complex CAD designs into high-precision parts and prototypes. The flexibility of our technology allows for the cutting of various metals and plastics, supporting intricate designs and features with high accuracy, essential for rapid prototyping, design for manufacturability, and the seamless integration of parts into larger assemblies.

ACMG’s laser cutting service provides you with the best solutions for your business. Whether you need intricate designs on mild steel or precise cuts on stainless steel, our experts and state-of-the-art machines are at your disposal.

Custom laser cutting services harness the precision of focused laser beams to intricately cut or engrave a variety of materials based on digital design files. This method, leveraging high-powered lasers, offers unmatched accuracy and versatility, making it indispensable across a myriad of industries, including aerospace and electronics. The process caters to a wide range of materials from metals like stainless steel and copper to non-metals such as wood and plastic materials. The adaptability of laser cutting, capable of producing complex shapes and intricate designs with excellent dimensional accuracy, revolutionizes manufacturing processes by converting flat patterns into detailed components.

Our CNC laser cutting service operates on the principle of translating your design file into precise cuts on the selected sheet material. By uploading a CAD file, clients initiate a streamlined manufacturing process where our fiber laser or CO2 laser systems meticulously follow the digital blueprint. This interaction ensures high fidelity in the production of components, whether for automotive applications or aerospace panels. The laser’s focused beam navigates through a wide variety of materials, achieving shapes and designs that conventional manufacturing techniques cannot, with speed and efficiency that significantly reduce production time.

Our laser cutting service excels in processing an array of metals and alloys, including spring steel, stainless steel, carbon steel, and galvanized Steel. Each material, chosen for its specific weight ratio or durability, undergoes a precise cutting process that maintains material integrity while achieving the desired 2D shape for electric components or electronic devices.

Plastic materials are also eligible for laser cutting, benefiting from the laser cutter’s ability to produce components for consumer electronics and robotics projects with clean edges and complex features.

Wood, a versatile material in manufacturing, is transformed by laser cutting into intricate designs for a variety of applications, from decorative boards to functional parts in manufacturing processes, highlighting the wide range of materials laser cutting technology accommodates.

Pricing is influenced by the choice of material and design complexity and from inexpensive materials to premium alloys, material thickness, especially thicker materials which require more laser power, and the density of the design file.

ACMG prides itself on continuous improvement and adherence to strict quality standards, demonstrated through certifications like ISO 9001. Our commitment to safety and excellence is further evidenced by OSHA certification and industry-specific accreditations. These credentials affirm our capability to meet diverse manufacturing needs, from intricate laser cut acrylic for the electronics industry to robust stainless steel components for aerospace, all while maintaining a focus on precision, speed, and innovation in laser metal cutting.