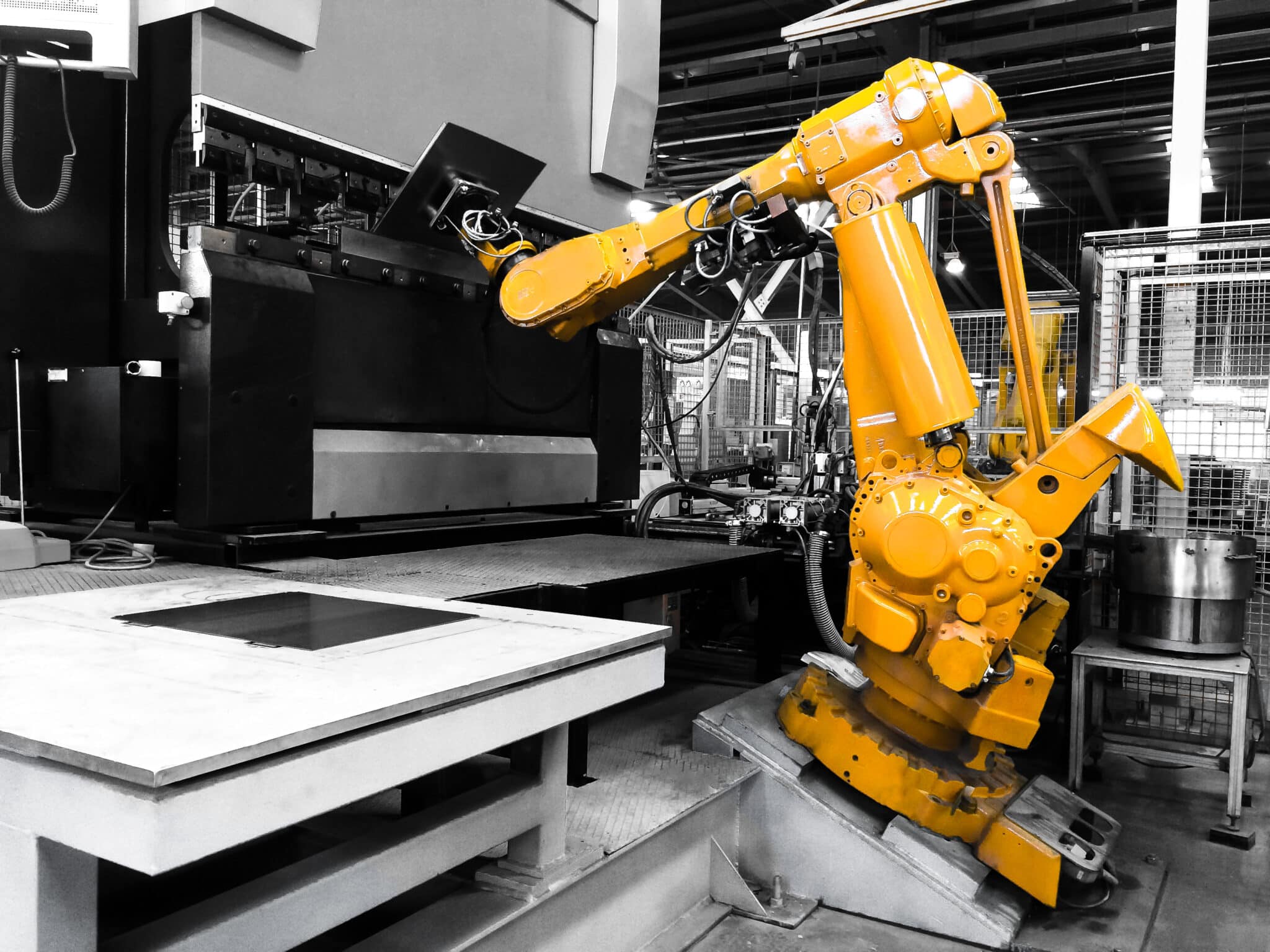

ACMG offers top-tier metal bending services, specializing in transforming sheet metal into complex shapes that fit your exact requirements. Our team uses state-of-the-art equipment, including hydraulic press brakes and laser cutting machinery, to ensure precision bending for a wide variety of applications.

Our sheet metal folding services leverage the latest machinery and techniques to provide intricate detailing on a wide variety of materials, including stainless steel, carbon steel, and more. Our expertise in metal fabrication processes ensures high tolerances and cost-effective solutions for your project.

From electrical enclosures to structural beams, our metal bending capabilities cater to a wide range of industries. We manufacture using a wide variety of steel, ensuring precision and durability in all applications.

ACMG makes it easy for you to get started on your metal bending project. Simply upload your 3D models or files, and receive an instant quote on your job. With ACMG, you can rest assured that you’re getting the most cost-effective solution for your manufacturing needs.

Experience the versatility of custom metal bending services with ACMG. We offer precise and intricate bending of a variety of materials into complex shapes using advanced machinery like air bending and rotary bending tools. Our high precision techniques meet the highest industry standards and provide a cost-effective solution for all your metal bending requirements.

Discover the quality and service difference with ACMG. Our highly skilled team, advanced machinery, and commitment to quality ensure the successful execution of your manufacturing project. Contact us today and let us help you meet your manufacturing objectives with ease and efficiency.

Discover the intricate process behind ACMG’s quality sheet metal bending. Our professionals harness the power of state-of-the-art machinery to manipulate metal sheets into a range of forms. This is more than just bending—it’s a process that transforms raw materials into metal components designed for a wide range of applications.

Whether you’re looking for custom bends or require specialized forming, ACMG has the tools and expertise to deliver. We work with a variety of sheet metal materials and our range of metal forming techniques enables us to shape these materials into an array of complex designs.

Each sheet metal bending process is a testament to our commitment to precision. From the initial design for manufacturing to the final inspection, every step of the way is executed with careful attention to detail, ensuring each product meets the tight tolerances required by our clients.

At ACMG, we pride ourselves on our extensive knowledge and experience in various sheet metal processes. Our team is adept at handling a wide array of sheet metal materials and tools to create custom metal components that match your specific requirements.

ACMG’s design for manufacturing approach ensures that every sheet metal forming project is efficient, cost-effective, and of the highest quality. We help you optimize your design to leverage our sheet metal processes and achieve the best possible outcomes.

With ACMG, the variety of shapes and types of metals we work with is virtually limitless. From spring steel bending to stainless and carbon steel, we have the tools and expertise to shape a broad spectrum of materials to fit your specific needs.

ACMG is your trusted partner for all your steel bending needs. We specialize in handling different types of steel, including spring steel, and are capable of achieving tight tolerances. Our variety of tools ensures precise shaping in every project.

Folding in sheet metal is the process of manipulating the metal, often using brake capacities of machines like hydraulic press brakes or laser cutters, to create defined bends or angles.

Sheet metal folding helps overcome various manufacturing challenges by offering control over shape and size, the ability to create complex sections, competitive pricing, and quick turnaround times. It’s particularly advantageous in industries like Power Generation and the production of electronic enclosures.

Metal folding encompasses several methods, including air bending, bottoming, and coining. These bending methods are typically executed using machines like press brakes or laser cutters.

Folding and bending in the context of sheet metal processes are often used interchangeably. Both refer to the practice of manipulating sheet metal into different shapes or angles.

The three primary types of folding techniques in metalwork include air bending, bottoming, and coining. Each method serves a unique purpose in the manufacturing process.

The ease of bending sheet metal depends on factors like the thickness of the material, the bend radius, and the tools used. With the right equipment, even the largest metal sheets can be manipulated into simple 90-degree bends and more complex shapes.

Several tools are used to bend sheet metal, including press brakes, folding machines, and laser cutters. The choice of tool depends on the requirements of the project and the desired result.

The rule for bending sheet metal is to maintain a bend radius at least equal to the thickness of the metal. This helps control the process of sheet metal bending and ensures the integrity of the final product.

While sheet metal bending offers numerous benefits, it can also introduce challenges such as potential distortion of the metal, limitations with extremely tight angles, and the need for specialized machinery.

Folding metal can make it stronger by increasing its structural integrity, particularly when creating cylinders or other complex shapes.

The two most common tools used for forming and folding sheet metal are press brakes and folding machines. Each tool offers unique capabilities, like the ability to create different sections and control the process piping.

The two most commonly used folding techniques are air bending and bottoming. These techniques, when controlled properly, can offer quick turnaround times and lower costs.

Metal folding is often referred to as bending in the manufacturing industry. It is a crucial part of the metal fabrication process, producing a variety of shapes and structures.

Bending and folding are achieved through a variety of tools, including press brakes, folding machines, and laser cutters. The choice of tool often depends on the specific project requirements and the metal being used.