In the fast-paced world of manufacturing and production, businesses often turn to contract manufacturers to meet their production needs efficiently and cost-effectively. Whether you’re a startup looking to bring a new product to market or an established company seeking to expand your production capacity, finding the right contract manufacturing partner is crucial. This article guides you through the process of finding the ideal contract manufacturer to meet your specific needs.

Understanding the Contract Manufacturing Process

Contract manufacturing is a strategic business practice that allows companies to tap into the specialized skills and resources of specialized professionals, reducing operational costs and speeding up the journey from product concept to market availability. This allows businesses to focus on their core competencies and achieve a more efficient, cost-effective, and streamlined production process. It’s a partnership model that’s particularly valuable in today’s competitive global marketplace.

Outsourcing Production

The contract manufacturing business model consists of companies outsourcing the manufacturing of their products to a specialized third-party manufacturer. This allows the hiring company, often referred to as the client or customer, to focus on its core competencies such as product design, marketing, and sales, while leaving the production process in the capable hands of experts.

Resource Leverage

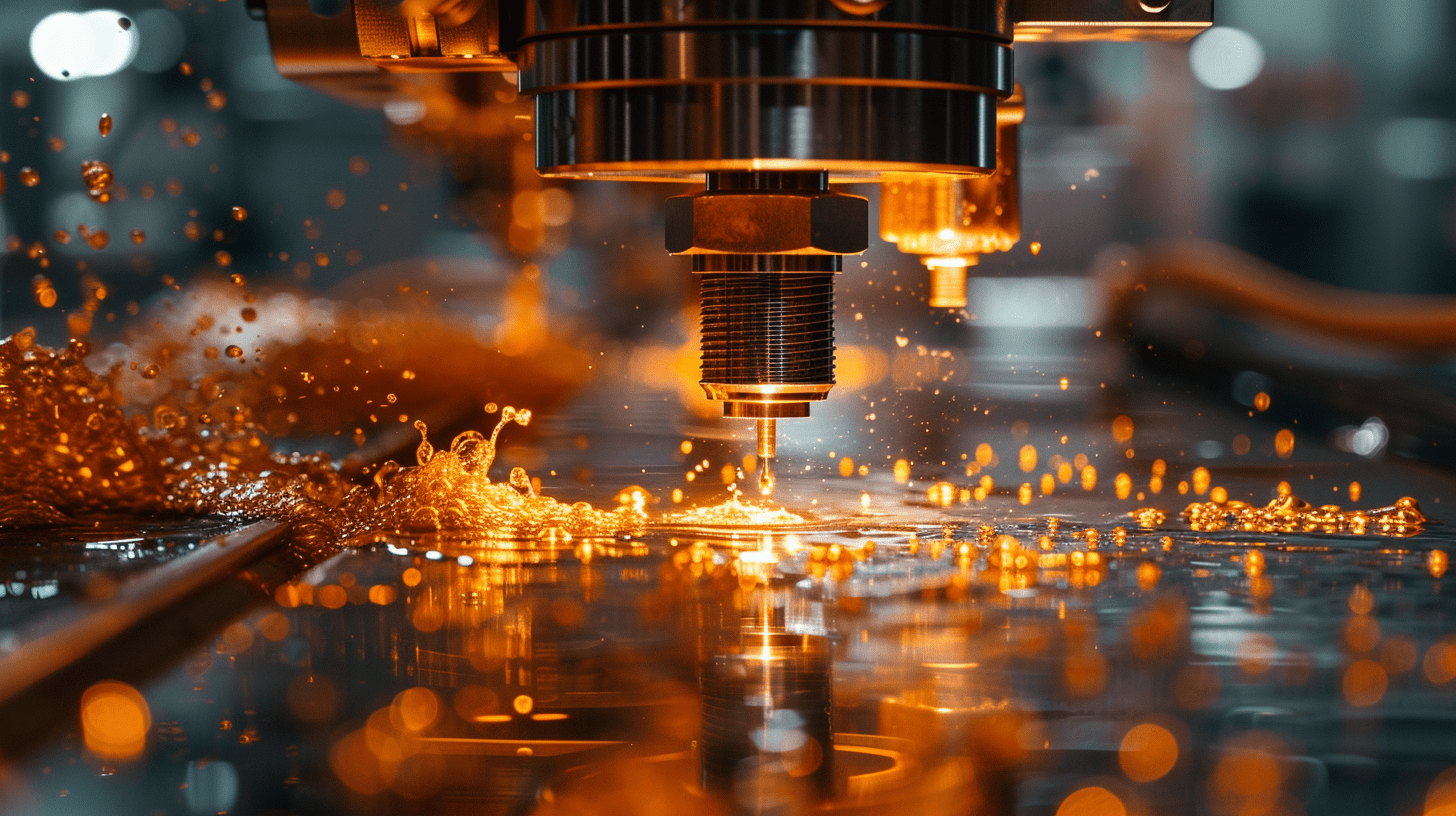

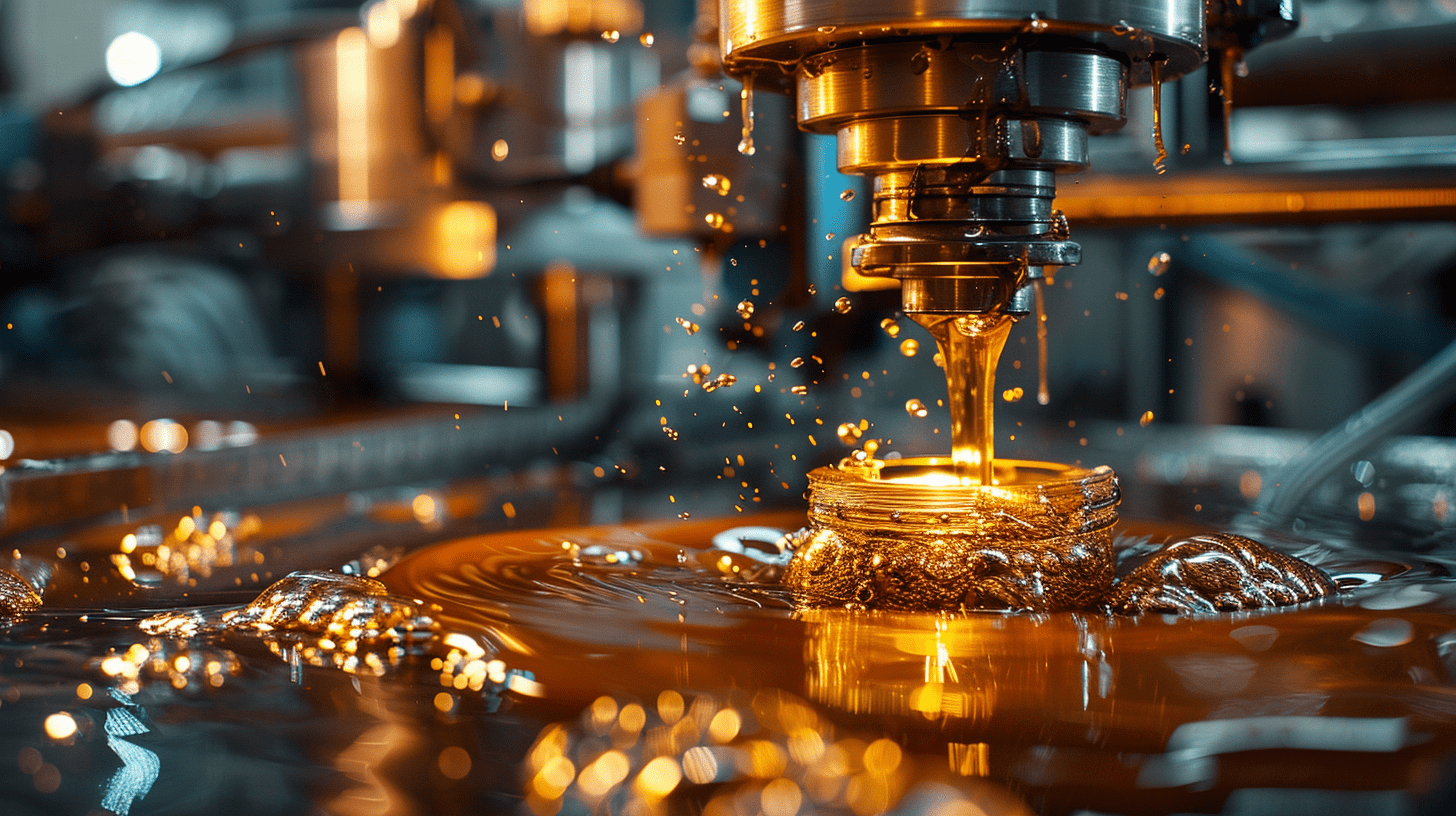

By partnering with contract manufacturers, businesses gain access to a wealth of resources and expertise. These manufacturers are equipped with the latest technology, skilled personnel, and extensive production facilities, all tailored to efficiently produce a wide range of products. Leveraging these resources allows the hiring company to avoid significant upfront investments in equipment, labor, and production space.

Time and Cost Savings

One of the primary advantages of contract manufacturing is the significant time and cost savings it offers. Investing in building or expanding in-house production facilities is time-consuming and expensive. Instead, companies can rapidly bring their products to market by outsourcing production. This efficiency is particularly beneficial for businesses looking to meet tight production deadlines or handle fluctuating demand.

Production Volumes

Contract manufacturers are flexible in terms of production volumes. Whether a client needs small batch sizes or mass production, a reputable contract manufacturer can accommodate the desired production volume. This adaptability ensures that companies can scale their production up or down as needed, optimizing costs and production efficiency.

Compliance and Quality Assurance

Experienced contract manufacturers are well-versed in industry-specific compliance standards and regulations. They maintain a strong focus on quality assurance throughout the production process, ensuring that the finished products meet the necessary standards. This is especially crucial for businesses operating in highly regulated industries or those with strict quality requirements.

Intellectual Property Protection

When working with a reputable contract manufacturer, businesses can establish clear contractual agreements to protect their intellectual property. This is a critical consideration for businesses with proprietary product designs or technologies, as it safeguards against the risk of unauthorized reproduction.

How to Protect Your Intellectual Property When Working With a Contract Manufacturer

Streamlining the Entire Process

Contract manufacturers specialize in specific manufacturing processes and have honed their expertise in those areas. This specialization allows for greater efficiency and higher-quality production. Additionally, they may offer various services beyond manufacturing, such as design for manufacturing (DFM) or assembly services, which can further streamline the entire production process.

A Wide Range of Additional Services

The best contract manufacturers offer a wide range of additional services, including product design, development, packaging, and even logistics support. These value-added services can help businesses bring their product ideas to life and get them to market more effectively.

Everything You Need to Know About Contract Manufacturing

How To Choose the Best Contract Manufacturer for Your Next Project

Finding the right contract manufacturer involves a comprehensive evaluation of your needs, potential partners, and their capabilities. By considering these factors, you can select a contract manufacturing partner that helps you produce high-quality products efficiently and meet your business goals.

1. Identify Your Needs

Before embarking on your search for potential contract manufacturers, it’s essential to identify your specific needs. Consider factors such as the type of products you require, production volumes, assembly requirements, and any additional services you may need. Knowing your business’s exact needs will help you narrow down your search.

2. Assess Their Capabilities

Look for contract manufacturers with a wide range of capabilities. They should be well-versed in various aspects of manufacturing, from product design and development to the production process itself. Consider whether they have the necessary manufacturing facilities, equipment, and personnel to meet your needs.

3. Quality Standards and Compliance

Check if potential contract manufacturing companies have a strong track record of quality and regulatory compliance. Ensuring that your partner complies with industry standards and regulatory requirements is crucial, especially if your products require regulatory compliance or involve intellectual property concerns.

4. Production Efficiency

Evaluate the potential partner’s production efficiency. It’s essential that they can meet your required delivery times and have a history of on-time delivery to customers. A robust customer service department is also a valuable asset. It will help you address any issues, concerns, or changes that may arise during the production process.

5. Financial Stability

Assess the financial stability of your potential contract manufacturers. Financial stability not only indicates a commitment to quality but also reduces the risk of unexpected disruptions in the production process, providing you with peace of mind and reliability in your partnership. A financially secure partner is more likely to invest in resources and equipment to meet your needs consistently.

6. Previous Experience

Consider the track record of potential partners. Have they worked on projects similar to yours? An experienced contract manufacturer will have a better understanding of the intricacies of your industry and specific product types.

7. Types of Contract Manufacturing

Different contract manufacturers specialize in various types of products and processes. Some may focus on consumer products, while others excel in complex, high-quality parts or industrial equipment. Choose a manufacturer that aligns with your product and business practice.

8. Customization and Additional Services

Determine if your potential contract manufacturer offers customization or additional contract manufacturing services, such as design for manufacturing (DFM) or Lean manufacturing techniques. These value-added services can help optimize your production process.

9. Budget Considerations

Create a budget for assembly, taking into account the contract manufacturer’s pricing structure. Remember to factor in batch sizes and potential adjustments to your budget as your project progresses. Your potential partner’s contract manufacturing capabilities should allow you to upscale or downscale operations to address market fluctuations.

10. The Final Decision

After thorough research and assessment, choose the contract manufacturing partner that aligns most closely with your business needs and objectives. This choice should support your product-to-market journey, from the design process to the finished product.

What Are The Typical Costs Associated With Contract Manufacturing?

Contract Manufacturing Services

At Alpha Contract Manufacturing Group, we pride ourselves on being at the forefront of the Industry 4.0 revolution. As a leading provider of industrial subcontracting services, we have the expertise and capabilities to handle a wide array of manufacturing projects, no matter how complex.

We specialize in the following manufacturing services:

- Industrial painting services

- Machining services

- Plastic manufacturing services

- Wood processing services

- Rubber processing services

- Laser cutting services

- Metal processing services

- Industrial welding services

- Electromechanics services

- Composite manufacturing services

- Industrial automation services

- Assembly manufacturing services

Our mission is to empower businesses, from small and medium-sized enterprises to multinationals, by offering a one-stop solution for all your industrial and manufacturing needs. Together, we can streamline your operations and significantly reduce production costs. Our expertise is your competitive advantage!

Frequently Asked Questions

What is contract manufacturing, and how does it differ from in-house production?

Contract manufacturing involves outsourcing production to specialized manufacturers, while in-house production is done within a company’s own facilities. Contract manufacturing allows businesses to focus on core competencies and leverage external expertise and resources, while in-house production requires significant investments in equipment and facilities.

How can I ensure the protection of my intellectual property when working with a contract manufacturer?

Protecting intellectual property involves clear contractual agreements, non-disclosure agreements (NDAs), and selecting a reputable contract manufacturer with a track record of IP protection. It’s essential to establish legal safeguards to prevent unauthorized reproduction or use of your proprietary designs or technologies.

What types of businesses can benefit from contract manufacturing services?

Contract manufacturing services can benefit a wide range of businesses, from startups to established companies, across various industries. Whether you need occasional production support, long-term partnerships, or specialized manufacturing capabilities, contract manufacturers offer flexibility and cost-effectiveness to suit diverse business needs.