Contract manufacturing has become an increasingly prevalent business practice in recent years. By delegating production to specialized third-party entities, companies can tap into global supply chains and leverage advanced manufacturing technologies, resulting in improved product quality, manufacturing speed, and cost-efficiency.

However, there are also disadvantages and considerations to be aware of. This article explores the historical roots of contract manufacturing, the impact of globalization and technology, and the advantages it offers in terms of cost-efficiency, expertise access, and competitive advantages. It also delves into future trends and innovations in this evolving field.

Key Takeaways

- Contract manufacturing involves a strategic partnership where one company produces goods or components for another, offering a range of benefits.

- Various types of contract manufacturing arrangements cater to specific business needs, including full-service, component manufacturing, and private-label manufacturing.

- The historical roots of contract manufacturing date back to industrialization and have evolved to meet globalization and efficiency demands.

- Key benefits of contract manufacturing include cost savings, expertise, access to new markets, and employee advantages.

Outsourcing Production: Understanding Contract Manufacturing

Contract manufacturing is a strategic arrangement where a company, known as the “contract manufacturer,” produces goods or components for another business, often referred to as the “contracting party.” This collaboration encompasses various aspects of production, from designing and sourcing raw materials to the manufacturing process itself.

The contract manufacturer assumes responsibility for aspects like product design, quality control, and cost savings, while the contracting party typically benefits from reduced production costs and expertise in manufacturing. There are various types of contract manufacturing arrangements, including private label manufacturing, where the final product carries the branding of the contracting party. Such partnerships may also include insurance and compensation programs to safeguard against potential issues, ensuring a high-quality end product and a smooth manufacturing experience.

The Historical Roots of Contract Manufacturing

The historical roots of contract manufacturing can be traced back to the early days of industrialization when outsourcing production to specialized third-party entities became a common practice. As businesses began to expand and globalize, the need for efficient and cost-effective production methods grew.

Contract manufacturing emerged as a solution, allowing companies to tap into global supply chains and leverage advanced manufacturing technologies. This practice not only expanded their reach beyond national boundaries but also provided access to expertise and specialized equipment.

By delegating production to contract manufacturers, businesses could redirect their savings towards research and development or marketing, ultimately gaining a competitive advantage through higher product quality and faster production times. Today, contract manufacturing continues to evolve, with trends such as increased automation, digitization, and a focus on sustainability shaping its future.

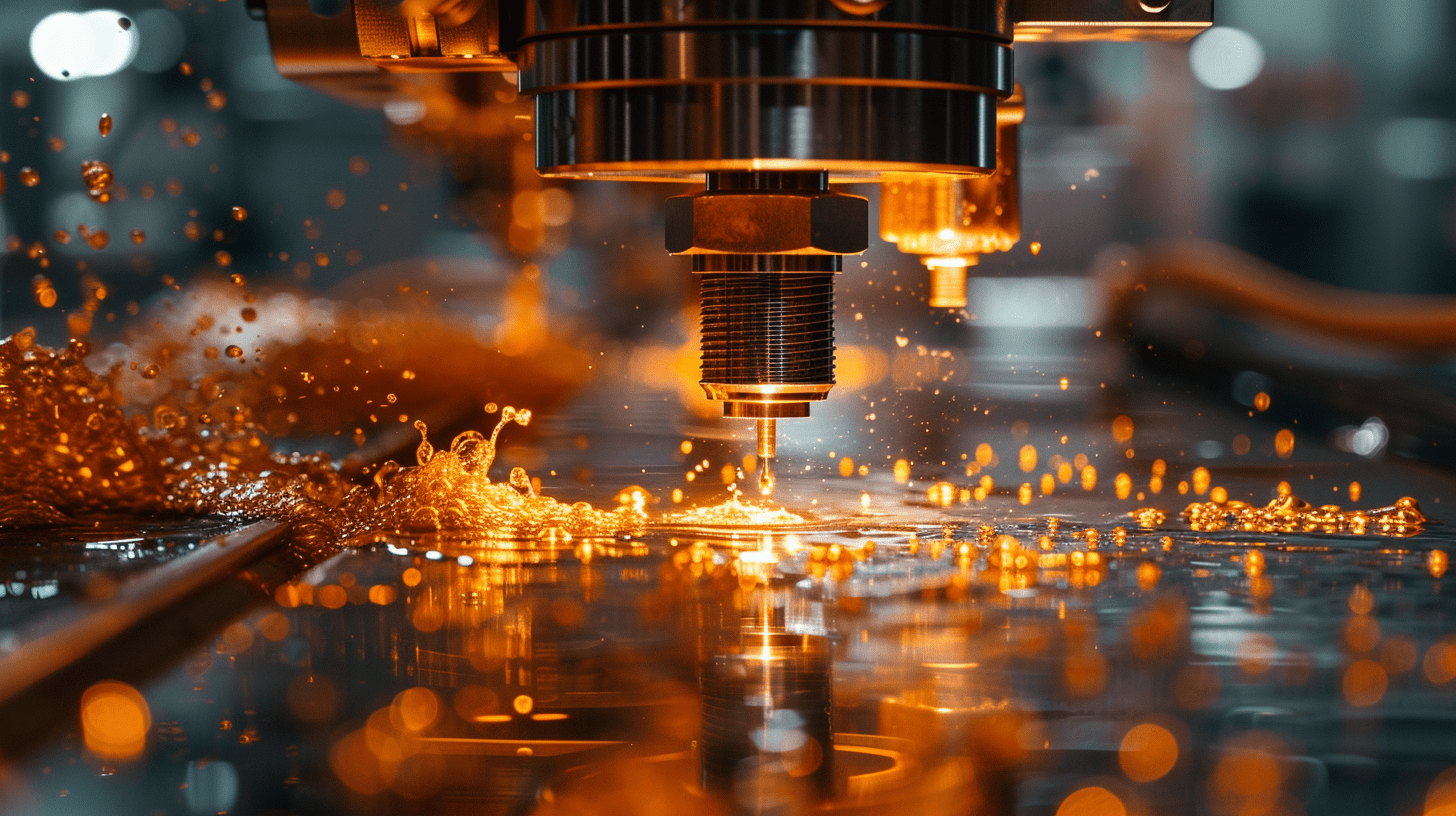

Contract manufacturing services

Types Of Contract Manufacturing

Manufacturing contracts encompass a variety of arrangements tailored to the specific needs and objectives of businesses. Here are some common types of contract manufacturing:

- Full-Service Contract Manufacturing: In this comprehensive arrangement, a contract manufacturer handles the entire production process, from design and procurement of materials to manufacturing, quality control, and packaging. The contracting company simply provides product specifications.

- Component Manufacturing: In this type, the contract manufacturer specializes in producing specific components or parts of a product. For example, they might be producing electronic components or packaging materials. These components are then supplied to the contracting company for assembly into the final product.

- Private Label Manufacturing: Contract manufacturers produce goods under the branding and label of the contracting company. This allows businesses to market and sell products without the need for in-house production.

Benefits Of Contract Manufacturing

Below, we highlight the advantages of entering into contract manufacturing agreements. These arrangements extend a wide range of benefits to both manufacturer and partner businesses, offering various types of benefits that go beyond the financial realm.

Cost Savings

Contract manufacturing offers cost savings by allowing businesses, especially tech companies, to sidestep the hefty expenses associated with establishing and maintaining a production facility. This approach significantly reduces labor costs, as skilled workers are often readily available through contract manufacturers. Moreover, overhead costs like utilities and facility maintenance become the responsibility of the manufacturing partner, not the business owners.

By streamlining the production process and optimizing resource allocation, contract manufacturing leads to reduced costs while ensuring a high-quality finished product. This financial advantage is a compelling reason why many businesses choose to partner with contract manufacturers to boost their competitiveness in the market.

Expertise and Efficiency

Contract manufacturing provides businesses with the advantage of expertise and efficiency. Manufacturers who specialize in the mass production of complex products have honed their skills and refined their processes over an extended time period. When integrated into a business model, this expertise leads to a highly efficient production process.

These specialized manufacturers are adept at optimizing workflows, reducing waste, and ensuring precision, all of which contribute to a shorter period of time for production and cost-effective manufacturing solutions, whilst still leaving you with a high-quality product at the end of the process. By leveraging the proficiency of contract manufacturers, businesses can streamline their operations and accelerate product development, ultimately gaining a competitive edge in the market.

What is the typical lead time for contract manufacturing products?

Access To New Markets

Access to new markets is a significant benefit of contract manufacturing. When companies forge a business relationship with contract manufacturers, they gain entry to markets and regions where these manufacturing facilities are based. This expansion aligns with their business plan and opens up opportunities for growth and increased sales.

Moreover, by outsourcing component manufacturing to these facilities, companies can tap into local expertise and resources, creating benefits for employees and enhancing the overall efficiency of their operations. This strategic collaboration allows companies to diversify their market presence and leverage the global reach of contract manufacturing companies, fostering business expansion and development.

Employee Benefits

Contract manufacturing can bring additional benefits to employees as well. When a company enters into a contract manufacturing agreement, it often results in increased production demands, leading to more job opportunities within the manufacturing facility, ideal for job seekers. This can mean more stable employment, better job security, and potential career advancement for workers.

Additionally, as manufacturers strive for efficiency and quality, they often invest in employee training and skill development, creating a more skilled and well-compensated workforce. In this way, contract manufacturing not only benefits businesses but also contributes positively to the livelihoods and job satisfaction of employees in the manufacturing sector.

Examples of Contract Manufacturing

Examples of Contract Manufacturing showcase the versatility and wide-ranging applications of this business strategy. Below, we explore real-world instances where companies leverage contract manufacturing to streamline production, optimize costs, and enhance their competitiveness in various industries:

- Electronics Contract Manufacturing (ECM): ECM specializes in the manufacturing of electronic components and devices. This type is common in the tech industry for products like circuit boards and consumer electronics.

- Food Contract Manufacturing: Food manufacturers produce food products on behalf of another company. This can include anything from snacks and beverages to frozen foods and sauces.

- Pharmaceutical Contract Manufacturing: Pharmaceutical companies often outsource the production of medications and drugs to specialized contract manufacturers to ensure compliance with strict regulatory standards.

- Cosmetic Contract Manufacturing: Beauty and cosmetic products are often produced by contract manufacturers, allowing brands to focus on marketing and product development.

- Apparel Contract Manufacturing: This type covers clothing and textile production, where clothing brands can outsource the manufacturing of their garments.

- Medical Device Contract Manufacturing: Similar to pharmaceuticals, medical device manufacturers partner with contract manufacturers to produce medical equipment and devices.

Future Trends and Innovations in Contract Manufacturing

Automation and digitization are transforming the landscape of contract manufacturing, with the integration of IoT devices, AI, and cloud computing. These technological advancements are revolutionizing the way products are manufactured, improving efficiency, and enabling faster production times. The utilization of IoT devices allows for real-time monitoring of production processes, ensuring optimal performance and minimizing downtime.

AI algorithms can analyze vast amounts of data to identify patterns and optimize manufacturing operations. Cloud computing enables seamless collaboration between contract manufacturers and their clients, facilitating efficient communication and data sharing. This integration of technologies not only enhances productivity but also enables contract manufacturers to offer more competitive pricing and higher quality products. As technology continues to advance, the future of contract manufacturing will see further automation and digitization, leading to even greater efficiency and innovation in the industry.

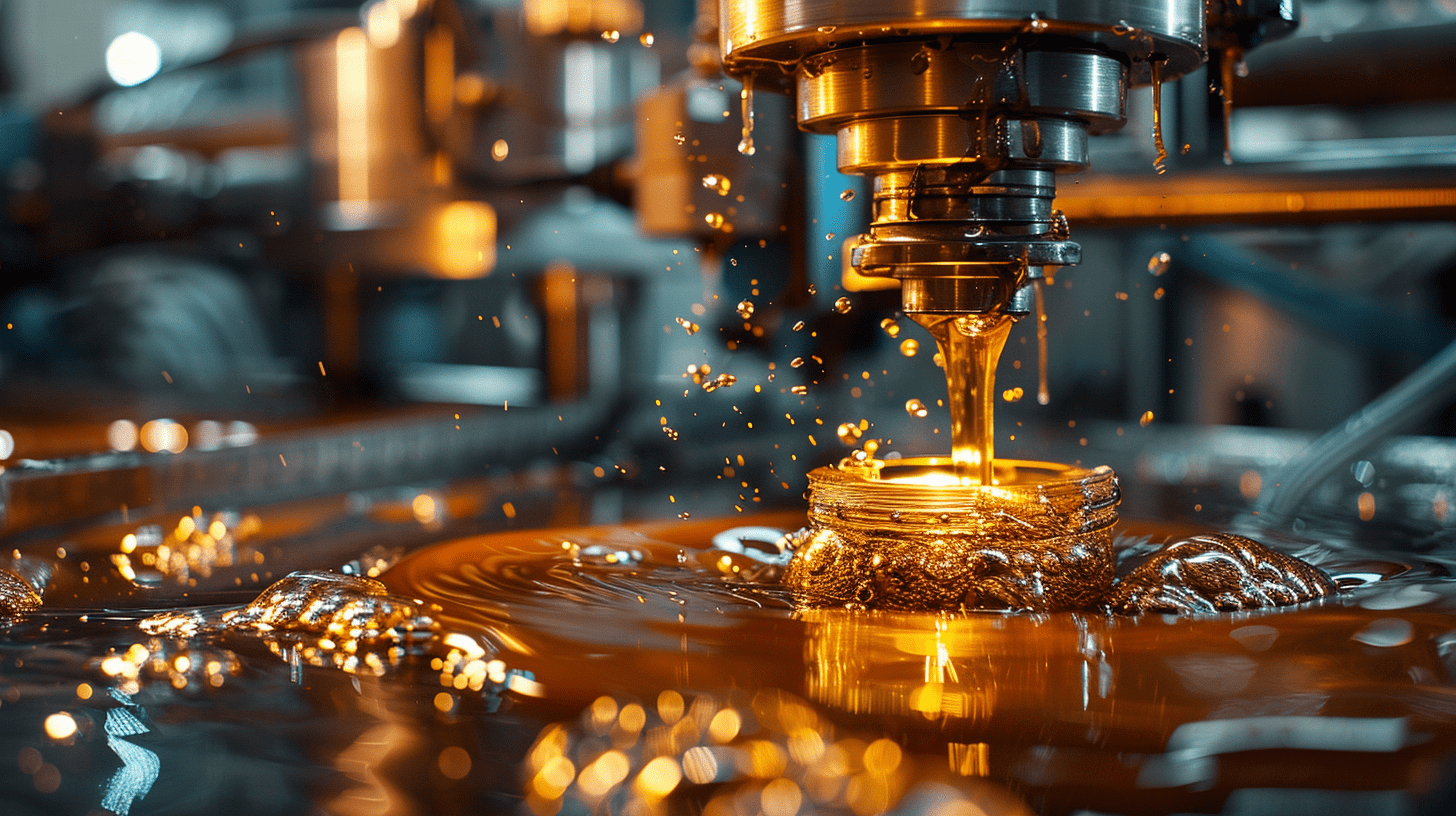

Contract Manufacturing Business Services

If you think your business would benefit from a contract manufacturing agreement, the Alpha Contract Manufacturing Group is here to help. We offer a comprehensive array of manufacturing services designed to meet the diverse needs of businesses across industries. Our offerings include wood processing, assembly manufacturing, and electronics manufacturing. With a focus on quality, efficiency, and customization, we are a trusted partner for companies seeking high-quality, cost-effective production solutions.

Frequently Asked Questions

Contract manufacturing typically involves the production of physical goods, while outsourcing can encompass a broader range of services beyond manufacturing.

Quality control is crucial in contract manufacturing to ensure that products meet specified standards and maintain consistent quality.

Intellectual property rights should be clearly defined in the contract, with considerations for product design.