In today’s fast-paced world, industries are increasingly focusing on sustainability to meet the growing environmental concerns. One area of particular interest is the coatings industry, where responsible e-coating is revolutionizing the way we approach surface protection and finishing processes. E-coating, also known as electrophoretic deposition, is a method of applying a protective coating to a metal substrate through an electrical current. This technology has gained widespread attention for its environmentally friendly properties and potential for creating a more durable industry.

The applications of e-coating extend across various sectors, including automotive, construction, and industrial manufacturing. As the coatings industry grapples with environmental concerns, sustainable solutions have become imperative for reducing the carbon footprint and minimizing environmental impact. In this article, we delve into the world of responsible e-coating, explore eco-friendly materials, and examine its advantages for environmental sustainability, all while shedding light on innovative developments and industry commitment to sustainability. Join us in uncovering the transformative potential of responsible e-coating and its pivotal role in shaping a durable and environmentally conscious industry!

What is E-Coating?

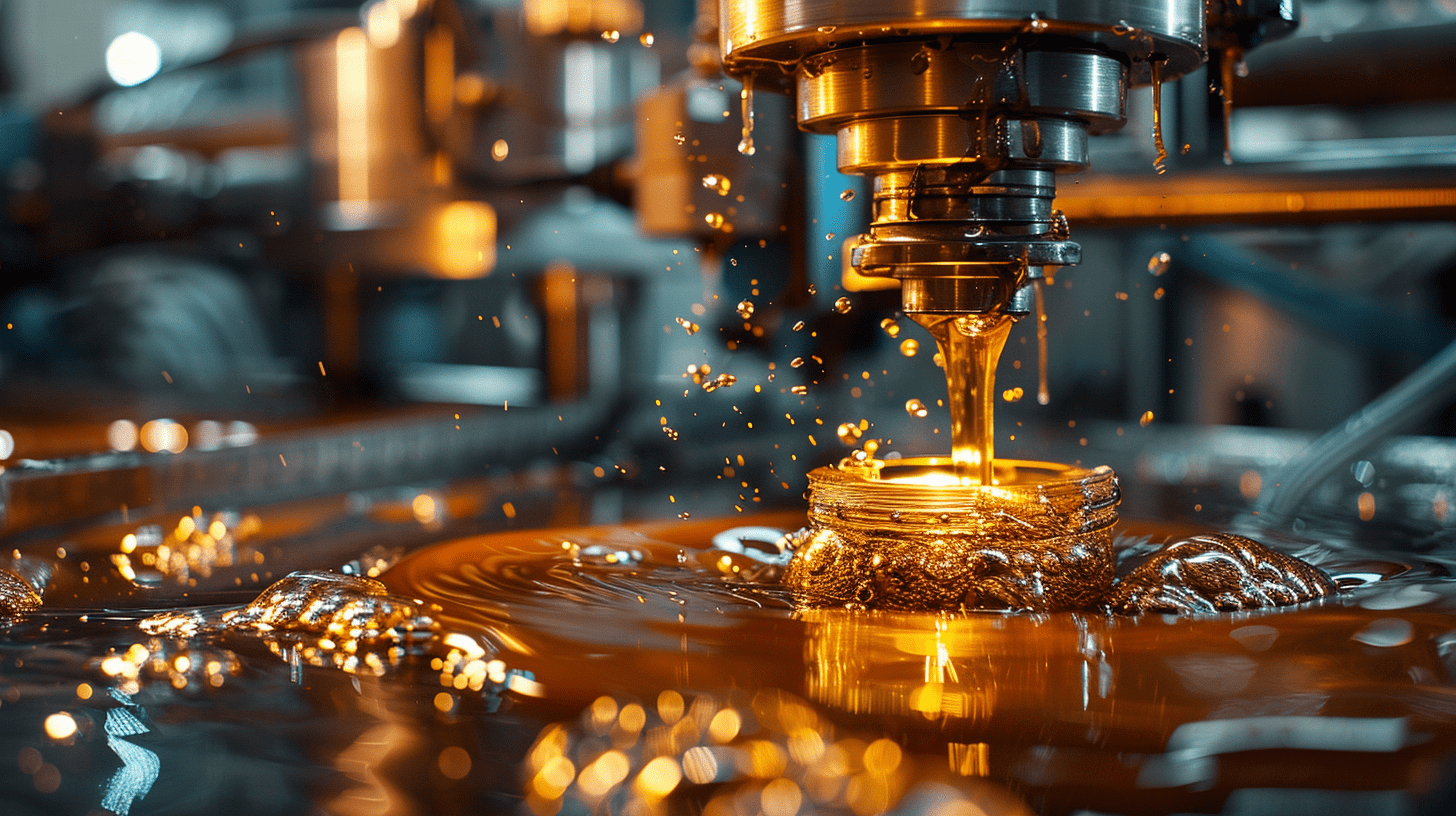

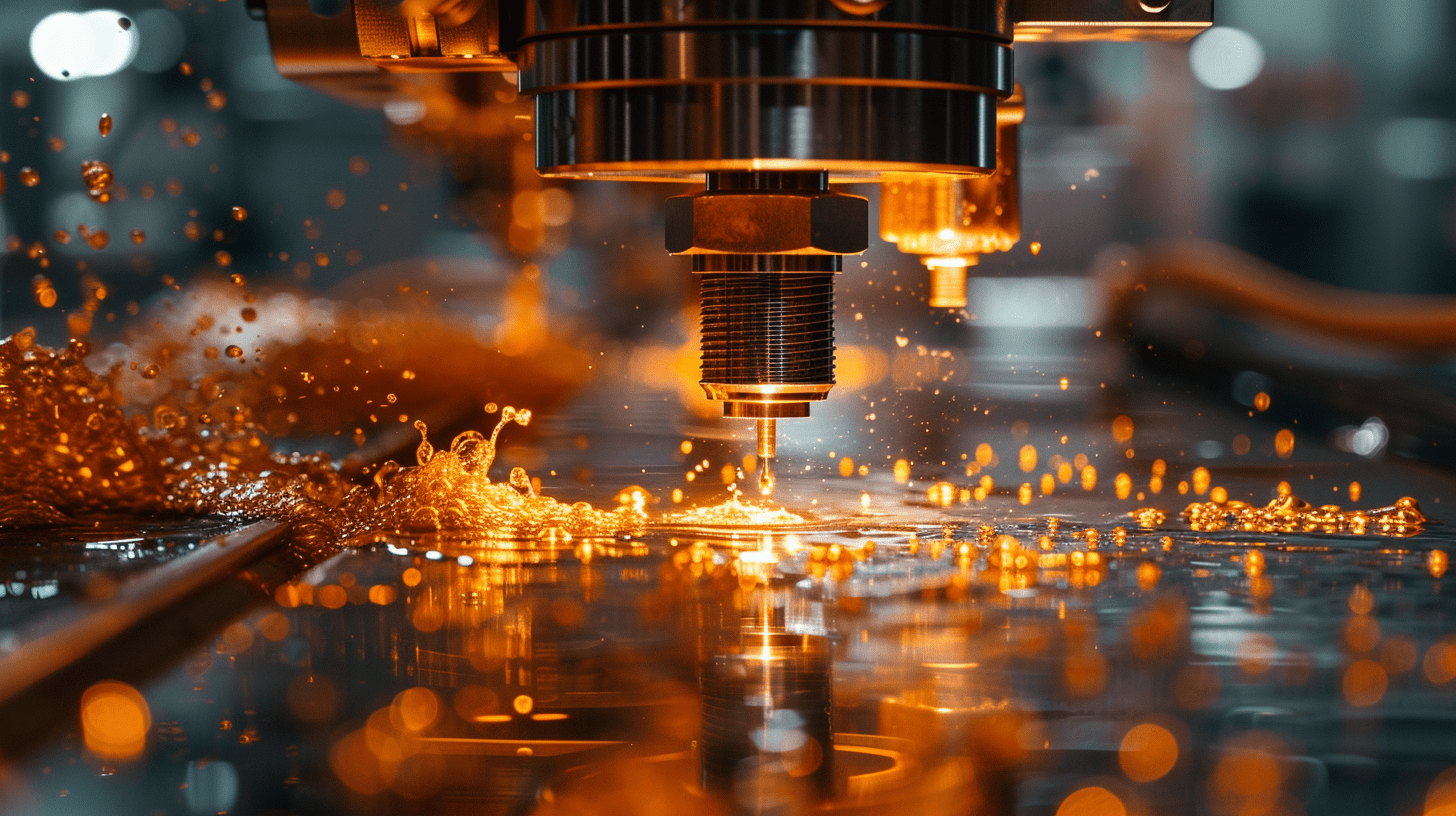

Electrophoretic deposition, commonly known as e-coating, is a method wherein electrically charged particles are deposited onto a conductive workpiece submerged in a water-based solution containing a paint emulsion. E-coating serves a crucial role as a protective coating in diverse industries, especially the automotive sector, by providing a uniform, thin layer that effectively resists corrosion.

This technology, with its low carbon footprint and minimal waste generation, is highly regarded for its environmental performance in the coatings industry. By embracing e-coating, industries can drive towards environmental sustainability and energy efficiency while maintaining high-quality standards and commitment to sustainability.

E-coating subcontracting solutions

The Applications of E-Coating

E-coating is utilized across a wide range of applications, owing to its durable and protective qualities. Here are the key applications of e-coating:

- Automotive Industry: E-coating is indispensable in the automotive sector for coating components like body shells, frames, wheels, and other parts requiring uniform protection against corrosion.

- Industrial Coatings: It is used in the protection of industrial equipment and machinery to extend their service life and maintain their performance in harsh environments.

- Consumer Electronics: Small electronic components and devices benefit from e-coating due to its precise application, which is critical for tiny parts.

- Appliances: E-coating is applied to appliances for a durable finish that can withstand regular use and cleaning.

- Metal Furniture: The coating is perfect for outdoor and indoor furniture, providing a protective layer that resists environmental exposure and wear.

- Military and Defense: Components and hardware employed in defense applications are often e-coated to ensure they meet stringent durability and quality standards.

Each application leverages e-coating’s energy savings and sustainable solutions to minimize environmental impacts while ensuring product longevity.

The Coatings Industry and Environmental Concerns

The coatings industry plays a crucial role in various sectors, yet it is also accountable for its environmental footprint. Recognizing this, the industry is pivoting towards sustainable coatings to mitigate environmental concerns such as carbon footprint, harmful chemicals, and waste generation.

This shift is evidenced by companies like Alpha Contract Manufacturing which focus on lowering energy consumption, encouraging minimal environmental impact. Their commitment to sustainability exemplifies the broader trend in industrial coatings, emphasizing energy efficiency and a reduced carbon footprint.

Sustainable E-Coating Solutions

E-coating brings multiple performance benefits, including exceptional corrosion resistance and consistent quality control. This translates into long-term asset protection, making it the preferred choice for various industries. Furthermore, e-coat systems pivot around water-based formulations, significantly decreasing the emission of volatile organic compounds (VOCs) and energy usage during curing. This transition to environmentally friendly practices underscores e-coating’s role as a bridge leading to a durable and eco-conscious industry.

Eco-Friendly Coating Material Uniformity

E-coating’s precise control over coating thickness and uniformity ensures that the optimal amount of paint is applied to achieve the desired level of protection. This precision minimizes material waste and conserves resources, making e-coating a sustainable option. Unlike processes that may require excessive amounts of paint to achieve adequate coverage, E-coating’s efficiency significantly reduces the overall environmental impact associated with coating applications.

By utilizing only what is necessary, E-coating promotes resource conservation and reduces the need for additional raw materials. This efficient material usage not only benefits the environment but also contributes to cost savings for manufacturers, further incentivizing the adoption of e-coating as an environmentally responsible solution for surface protection and finishing.

Energy Efficiency and Energy Savings in Coating Processes

Companies like Alpha Contract Manufacturing Group are extending their commitment to sustainability by utilizing low temperatures to ensure less energy is used. This shift not only slashes energy consumption during the drying and curing stages but also underpins the sector’s dedication to environmental performance.

Similarly, advances in energy-efficient technologies and the smart optimization of production schedules further reduce energy usage. Manufacturers are implementing high-efficiency ovens and employing curing methods, such as infrared or ultraviolet radiation, to enhance energy efficiency while simultaneously lowering operational costs.

Longer Coating Lifespan

E-coating’s exceptional corrosion protection and durability result in surfaces requiring less frequent recoating or replacement, thereby extending the coating’s lifespan. This longevity reduces the environmental impact associated with coating maintenance and disposal. By minimizing the need for frequent recoating, e-coating helps conserve resources and reduces the overall volume of coating materials consumed over time.

Additionally, the reduced frequency of recoating translates to fewer chemicals being released into the environment during application and disposal processes. Overall, the longer lifespan of e-coatings contributes to a more sustainable approach to surface protection by decreasing the frequency of coating applications and minimizing the associated environmental footprint.

Case Study: Alpha Contract Manufacturing Group (ACMG)

The Alpha Contract Manufacturing Group (ACMG) presents a compelling example of how a company within the coatings industry can embrace the sustainability wave. ACMG’s venture into responsible e-coating demonstrates both a commitment to the environment and an astute business strategy. The e-coating technology employed by ACMG operates at considerably lower temperatures than traditional methods. As a result, the process boasts greater material and energy efficiency—key components in reducing both cost and environmental footprint.

ACMG’s dedication to sustainability doesn’t stop at energy savings. The process itself, chosen for its superlative performance, produces minimal waste and uses coating materials with lower environmental impact. In harmony with the urgent priority to safeguard our planet, ACMG has established its e-coating solutions as a sustainable alternative for various applications.

Difference between manufacturing and contract manufacturing

Addressing Energy Consumption and Waste Generation

The protective metal coatings industry is actively redefining its operational standards to align with the principles of environmental stewardship. Central to this transformation is the dual challenge of curtailing energy consumption and waste generation—a pivotal move towards a durable industry. Manufacturers are deploying strategies that not only reduce the ecological footprint but also bolster the economic viability of their practices.

Leveraging efficient resource utilization and responsible waste management techniques, e-coating and powder coating systems stand out as exemplars of sustainability. They not only offer excellent protection for a wide range of applications, especially in the automotive industry, but they also embody the drive for ecological and economic balance. By embracing these advanced technologies, manufacturers are making tangible progress in shielding the environment from the adverse effects of coating operations.

E-Coating Sustainability Vs. Traditional Liquid and Powder Coating

E-coating’s environmental responsibility is showcased through its solvent-free process, which eliminates the release of harmful fumes typical of traditional liquid coatings. Significantly reduced VOC emissions distinguish e-coating as the greener alternative, curbing the air pollution that accompanies both liquid and powder coatings. Moreover, with its high transfer efficiency, e-coating minimizes waste generation, unlike traditional methods, which are often less efficient and produce more excess material.

In terms of resource management, e-coating utilizes water-based solutions, presenting a stark contrast to the solvent-based coatings of traditional methods that pose greater environmental risks. This distinction is critical for those committed to sustainability and minimizing their ecological footprint. Furthermore, the superior corrosion protection and durability provided by e-coating means metal components last longer, decreasing the frequency of maintenance and reapplication which is more common with other coatings.

Sustainability Features of E-Coating:

- No solvents; no harmful fumes

- Lower VOC emissions for better air quality

- Enhanced transfer efficiency, less waste

- Water-based solutions, lower ecological impact

- Superior durability, longer lifespan of components

This evidence places e-coating at the forefront of sustainable solutions within the coatings industry, fulfilling a responsibility to both environmental performance and industry demands.

Invest in Sustainable E-Coating Solutions

Alpha Contract Manufacturing Group provides comprehensive industrial subcontracting services tailored to meet diverse manufacturing needs. From precision machining and assembly to surface treatment and quality assurance, we offer end-to-end solutions to streamline production processes and optimize efficiency.

Our full range of sub-contracting solutions includes:

- Machining

- Plastics

- Wood Processing

- Rubber Processing

- Laser Cutting

- Metal Cutting

- Mechanically Welded Assembly

- Electromechanics

- Industrial Painting

- Composites

- Industrial Automation Robotics

- Assembly Manufacturing

With state-of-the-art facilities and a team of experienced professionals, we ensure high-quality results and on-time delivery for every project. Whether it’s prototyping, small-batch production, or full-scale manufacturing, Alpha Contract Manufacturing Group delivers reliable and cost-effective solutions to clients across various industries, fostering long-term partnerships and driving success in the competitive market.