CNC machining has revolutionized the manufacturing industry by enabling the efficient production of custom metal and plastic parts. By uploading a CAD file, customers can obtain instant quotes, lead time, and design feedback. Skilled machinists program CNC machines based on these CAD models, ensuring precise cutting of metal and rigid plastic materials.

Alpha Contract Manufacturing Group offers enterprises whose expertise extends to rapid prototyping, small-batch machining, and high-volume production, catering to industries such as aerospace, medical, robotics, electronics, and industrial. All ACMG’s partners have certifications in ISO 9001:2015, ISO 13485, and AS9100D guarantee adherence to strict quality standards.

When it comes to machining services, there are several options to choose from. Alpha Contract Manufacturing Group offers industrial sub-contractors offering precision machining, CNC machining and subtractive manufacturing processes.

Precision machining involves creating parts with extremely tight tolerances, and is an ideal process for industries and manufacturers that require high accuracy and intricacy. Whether you require intricate components or complex assemblies, ACMG offers you skilled engineers and technicians who will meticulously craft each piece with unparalleled precision and attention to detail.

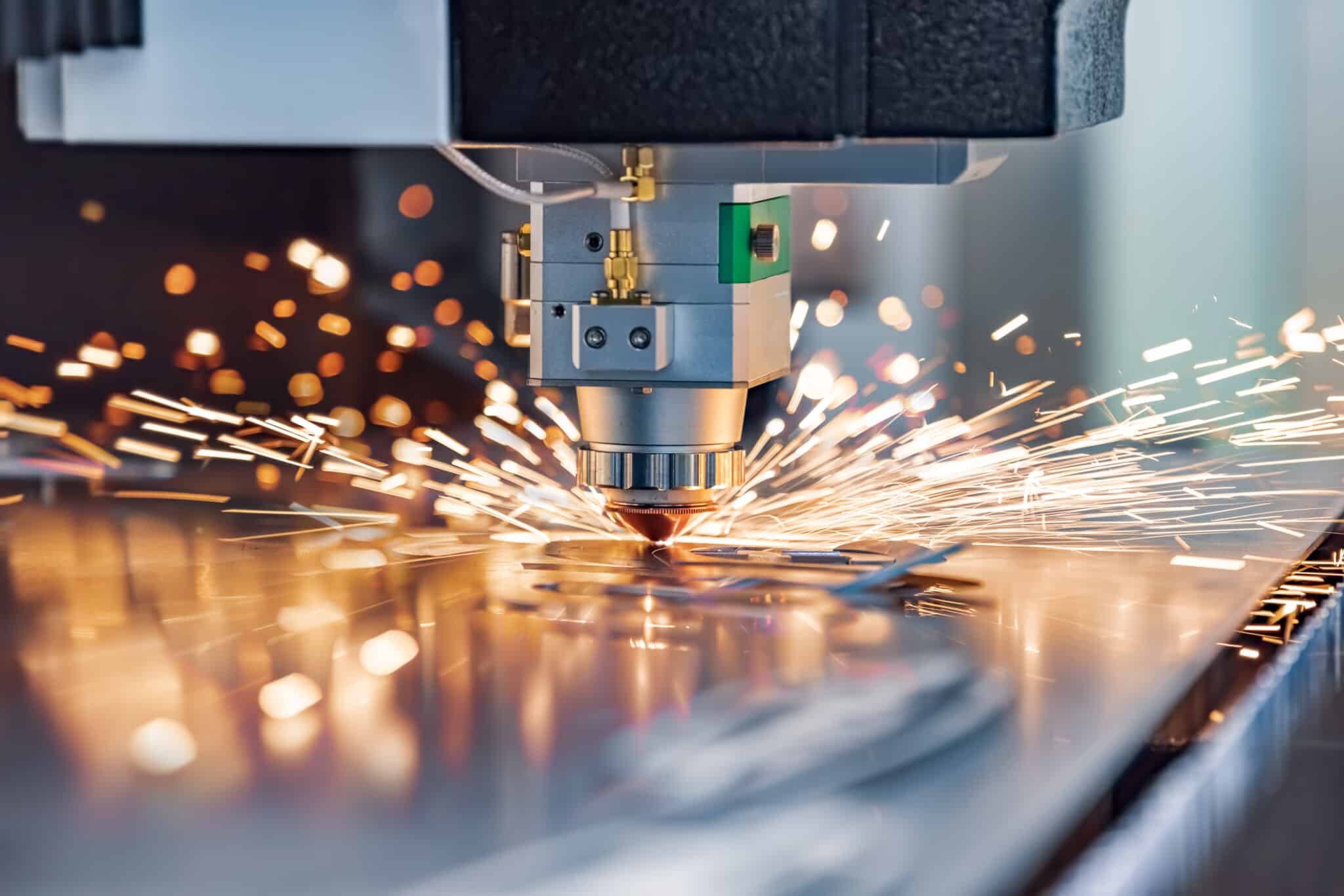

CNC machining (Computer Numerical Control) utilizes computer software to control the machining tools, resulting in precise and efficient production. ACMG is the solution for manufacturers looking for superior CNC machining services that will propel their processes to new heights of efficiency and precision.

From rapid prototyping to large-scale production runs, our state-of-the-art facilities in and meticulous attention to detail ensure that every component we manufacture meets the highest standards of quality and accuracy.

The subtractive manufacturing process works with material being removed to shape the desired part. This process is commonly used for creating prototypes or custom parts.From CNC milling and turning to grinding and drilling, ACMG’s partners have skilled technicians and engineers that utilize advanced equipment to craft complex components with utmost precision and accuracy.

Our commitment to excellence ensures that every piece we produce meets the highest quality standards, no matter the industry or application. Whether you need single prototypes or high-volume production, Alpha Contract Manufacturing Group delivers unparalleled subtractive manufacturing services that guarantee exceptional results.

One of the notable benefits and uses of this manufacturing process lies in its ability to achieve high accuracy and repeatability in the production of various components for industries such as aerospace, automotive, consumer electronics, robotics, and medical devices. This is true for metal machining, plastic machining and others.

CNC machining offers advantages in terms of precision and consistency, as it uses computer-controlled machines to remove material and shape it into the desired form. This level of control allows for the creation of complex geometries and intricate designs that may be difficult to achieve with other manufacturing methods.

Additionally, CNC machining is suitable for both rapid prototyping and end-use production, providing flexibility in meeting different manufacturing needs. With its wide range of material compatibility and the ability to produce parts on demand, CNC machining has become a common and valuable process in many industries.

To ensure the quality of the final products, quality assurance measures are implemented throughout the CNC machining process, including ISO certifications, ITAR registration, and additional inspections. These measures are crucial in maintaining the accuracy and precision of the machined parts.

These quality assurance measures provide customers with confidence in the reliability and performance of the custom metal and plastic parts produced through CNC machining.

Machining is a precision manufacturing process that involves the removal of material from a workpiece using techniques like cutting, milling, and turning to create the desired shape or form.

CNC machining, short for Computer Numerical Control machining, is a subtractive manufacturing process that employs computer-controlled systems to accurately and precisely remove material from a workpiece. This process enables the transformation of raw materials into desired shapes with exceptional accuracy and repeatability.

CNC machining requires skilled machinists who program computer-controlled machines using CAD (Computer-Aided Design) models. These machines are then capable of cutting various materials, such as metals and rigid plastics, with an unparalleled level of precision. The use of CAD models allows for complex designs and intricate geometries to be translated into tangible products. However, such complexity can pose challenges in terms of programming and execution.

CNC machining has found extensive applications in diverse industries, including aerospace, automotive, consumer electronics, robotics, and medical devices. Initially developed during World War II to cater to the increasing demand for industrial products, CNC machining has evolved significantly with advancements in technology. Today, it stands as a versatile and indispensable manufacturing technique, providing exceptional benefits and opportunities.

Our machining services include CNC milling, CNC turning, drilling, grinding, and more. We cater to various industries, offering prototyping, small-scale production, and large-volume manufacturing.

Understanding the different types of machining processes is crucial for achieving precision in the manufacturing industry. From CNC machining to turning, milling, and grinding, each process has its unique advantages and applications. By utilizing these machining processes effectively, manufacturers can create high-quality components and parts for various industries.

One of the most commonly used machining processes is CNC (Computer Numerical Control) machining, which utilizes computer-controlled machines to create precise and complex parts.

Another popular machining process is turning, which involves rotating the workpiece while a cutting tool removes material to create cylindrical shapes.

Milling is another common process where a rotating cutter removes material from a stationary workpiece to create flat surfaces, slots, and contours. When it comes to milling, there are various options to choose from, such as face milling, end milling, and slot milling. Each technique offers its own advantages and is suitable for specific applications.

Grinding is used to achieve high precision and smooth finishes by using an abrasive wheel to remove material.

There are also specialized machining processes such as drilling, which creates holes in materials, and broaching, which uses a toothed tool to remove material in a linear motion.

These processes, along with others like honing, lapping, and electrochemical machining, offer a wide range of options for creating precision parts from various materials.

Machining services play a crucial role in various industries, offering precise manufacturing solutions for a wide range of applications. With a focus on tight tolerances and exceptional quality, these services are particularly beneficial to the following industries:

In the aerospace industry, precision machining services are essential for producing critical components that meet stringent specifications. Machining plays a key role in manufacturing parts for aircraft engines, structural components, landing gear, and avionics systems. With CNC machining, complex geometries can be achieved, ensuring optimal performance, weight ratio, and safety.

The automotive industry relies on machining services for the production of components with high precision and durability. From engine parts to transmission components, braking systems to suspension components, machining ensures the tight tolerances and excellent strength required for reliable and efficient vehicles. CNC machining allows for the rapid prototyping of new automotive designs and the production of one-off prototypes.

In the electronics industry, machining services are vital for creating intricate components used in devices such as computers, smartphones, and consumer electronics. CNC milling and turning enable the production of precise parts with complex geometries, while electrical discharge machining (EDM) is employed for cutting hard metals like copper with high electrical conductivity.

Machining services play a critical role in the medical device manufacturing sector, where precision and quality are of utmost importance. These services are used to create intricate components for surgical instruments, orthopedic implants, dental tools, and diagnostic equipment. CNC machining ensures tight tolerances, complex geometries, and corrosion resistance, while the availability of a wide range of materials allows for the selection of biocompatible options.

Absolutely! Machining services, especially CNC machining, are ideal for rapid prototyping. We can quickly produce prototypes based on your designs, allowing you to validate and refine your product before full-scale production.

When it comes to machining, the choice of materials is crucial for achieving desired outcomes. At our facility, we offer comprehensive machining capabilities for a wide range of materials, including metals, plastics, and composites. Each material offers unique properties and characteristics that are considered during the machining process. Here are some of the materials we work with:

We accept 3D CAD file formats like STEP, IGES, and STL, which accurately represent the part’s geometry. These accurate drawings facilitate seamless communication between you and our machining team.

When it comes to finding the perfect machining service provider, it’s essential to choose one that aligns with your specific needs and delivers top-notch results. The right machining service provider can make all the difference in the quality and efficiency of your manufacturing processes.

By considering these factors, you can choose the right machining service provider that meets your specific needs, delivers top-notch results, and offers competitive pricing.

ACMG offers competitive and cost-effective machining services to meet the needs of both small and large businesses. The machining services provided by ACMG includes CNC milling, turning, grinding, tapping, boring, broaching, drilling, honing and lapping.

The cost for these machining services varies depending on the complexity of the project. Generally speaking, ACMG has a minimum charge for its machining services, while for larger projects, ACMG may also offer discounted rates. By simply uploading your CAD file, you can instantly generate a CNC machining quote. What’s more, our quoting service is entirely free of charge. We only require you to create an account to safeguard your intellectual property.

Outsourcing machining services of all sizes can provide companies with a cost-effective solution and peace of mind, allowing them to focus on their core competencies and achieve greater operational efficiency.