E-Coating represents a revolution in electrodeposition technology, allowing us to leverage superior sustainable solutions with superior corrosion resistance and a transformative impact in various sectors. In this article, we take a deeper look at electrodeposition technology and how it is shaping a future where efficiency, durability, and eco-consciousness converge.

The Science Behind Electrodeposition Coating

Electrodeposition coating, or E-coating, stands at the forefront of revolutionary advancements in industrial paint applications. This sophisticated process involves the precise application of paint onto a conductive surface through the utilization of electric current. The methodology is intricate yet highly efficient, ensuring a uniform and durable coating.

E-coating represents an innovative solution that transcends traditional painting techniques. Its unparalleled ability to provide an even and consistent layer of paint plays a pivotal role in safeguarding a wide array of assets. From vehicles to complex machinery and various components, E-coating applications serve as a formidable shield against the corrosive forces that threaten longevity and reliability.

How Does the Electrocoating Process Work?

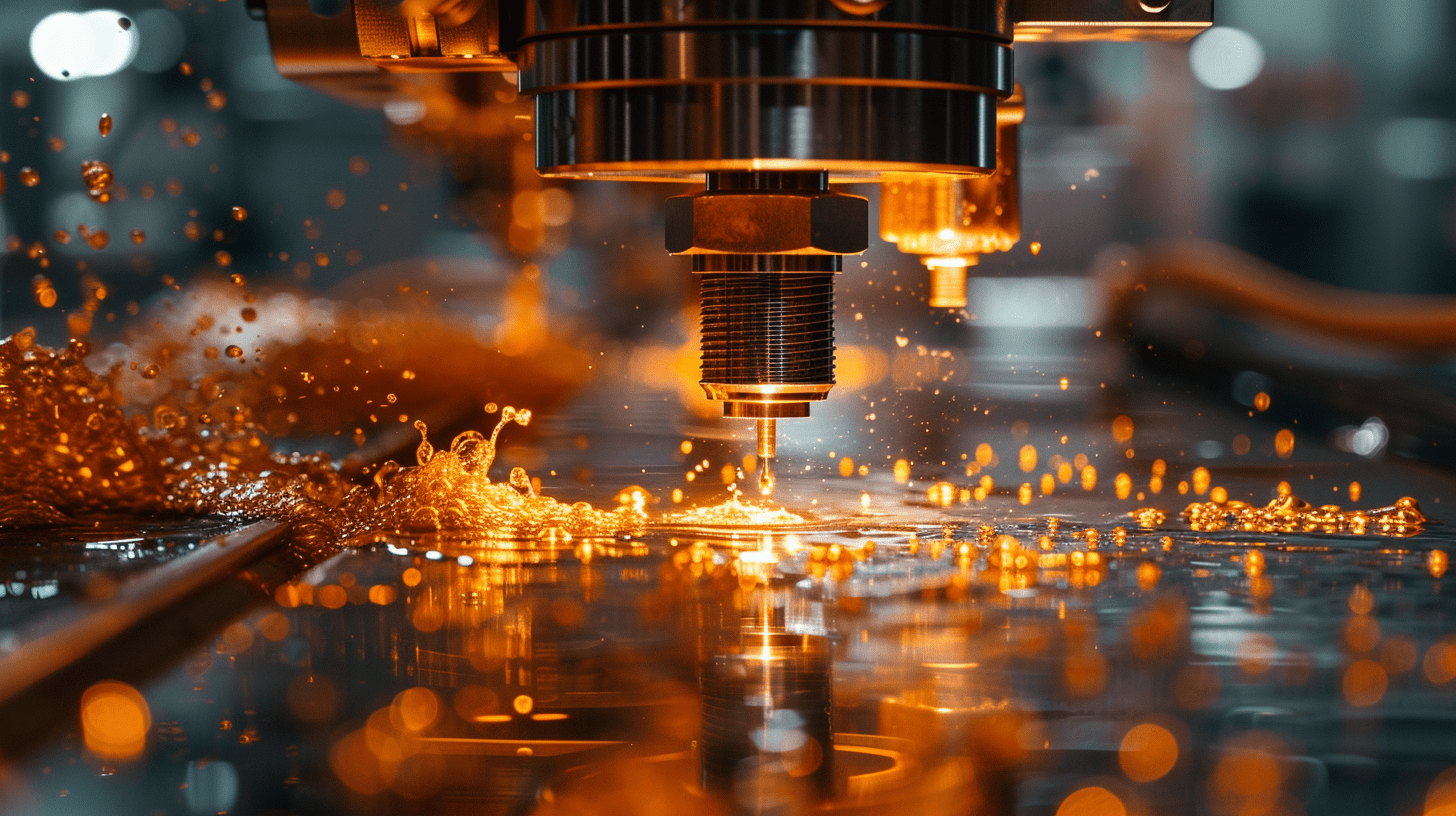

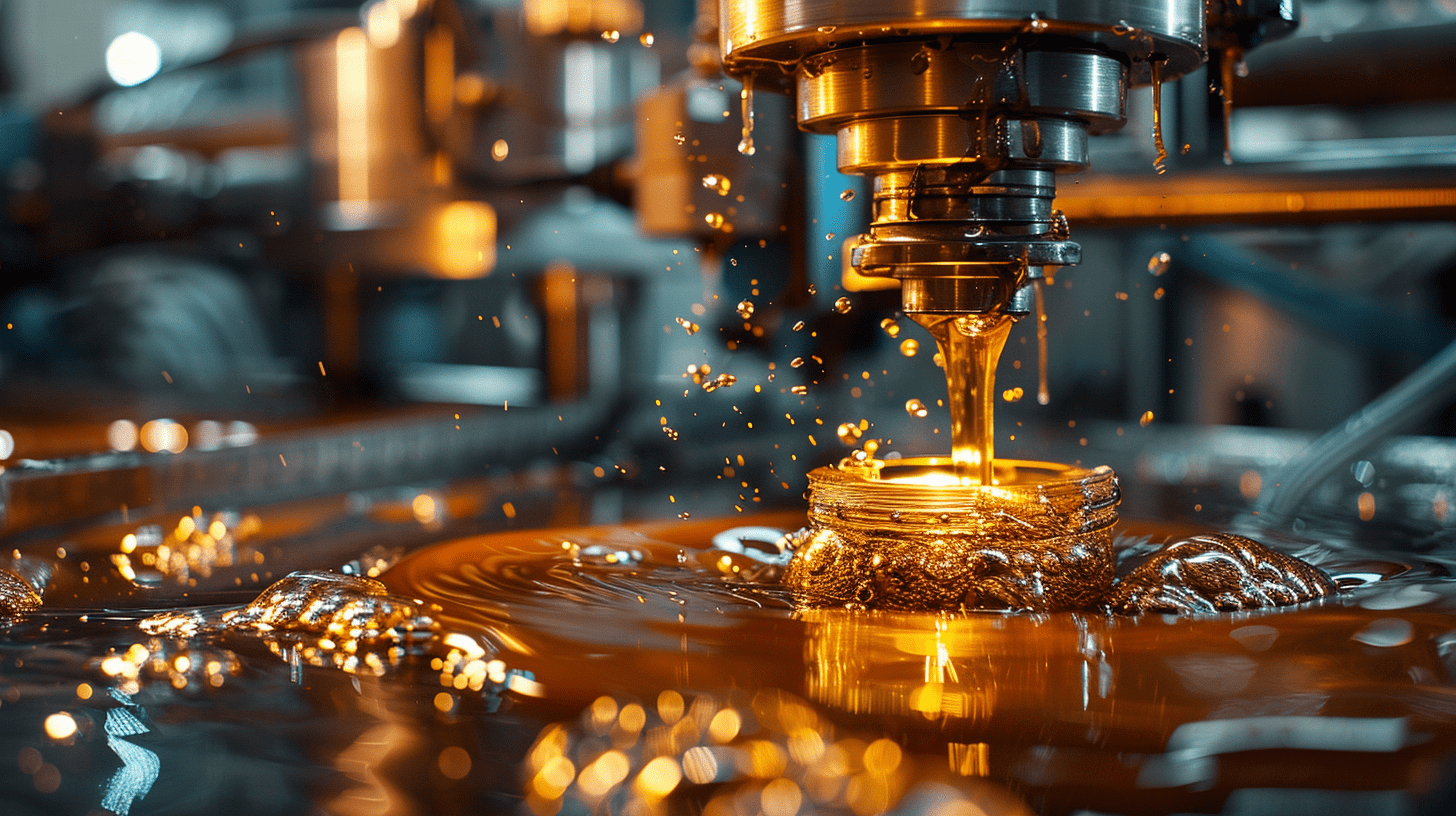

The E-coating process begins with the immersion of the object to be coated into a bath of specially formulated paint. Utilizing the principles of electrochemistry, an electric current is then applied, causing the paint particles to migrate and deposit uniformly across the conductive surface. This innovative application process ensures comprehensive coverage, reaching even the most intricate and hard-to-reach areas, leaving no room for vulnerabilities.

The result is a resilient and protective coating that adheres seamlessly to the substrate, creating a barrier against environmental elements, chemical exposure, and the wear and tear of daily use. This exceptional corrosion resistance not only enhances the aesthetic appeal of the coated object but, more importantly, significantly extends its operational lifespan.

Key Steps in Electrodeposition Coating

- Preparation of Coating Bath: A specially formulated coating solution, typically consisting of resins, pigments, and other additives, is prepared. This forms the paint bath.

- Immersion of the Object: The object to be coated is immersed into the coating bath, creating an environment conducive to the electrodeposition process.

- Application of Electric Current: An electric current is introduced into the bath. The object acts as the cathode (negatively charged electrode), while the coating material is positively charged.

- Electrophoresis: Charged paint particles migrate towards the oppositely charged object due to electrophoresis. This movement is driven by the electric field established in the bath.

- Deposition on the Cathode: As the paint particles reach the cathode (the object to be coated), they deposit uniformly across its surface. This deposition is a result of electrochemical reduction reactions taking place at the cathode.

- Formation of Coating Film: The deposited paint particles react and polymerize to form a continuous and uniform coating film on the object. This film adheres tightly to the substrate, providing excellent coverage.

- Rinsing and Curing: Excess coating material is rinsed off, and the coated object undergoes curing, where the coating is baked to achieve the desired hardness and durability.

The electric field created during electrodeposition ensures that the coating thickness remains consistent across the entire surface of the object. This uniformity is challenging to achieve with other coating methods. The controlled application of electric current, coupled with chemical reactions, results in a protective coating that excels in both aesthetics and performance, making E-coating a cornerstone in modern industrial coating processes.

The Best Surface Finishing Options for Sheet Metal Parts

Current Trends and Future Innovations: The Impact of E-Coating on Different Sectors

The E-coat market is evolving at breakneck speed, giving us a glimpse into the future of sustainable technologies. With its excellent corrosion resistance, energy efficiency, and suitability for various applications, E-coating is not just a present solution but a future-proof innovation shaping the landscape of industrial paint.

Construction Sector

In the realm of construction, E-coating technology emerges as a game-changer, redefining the standards of durability. As buildings and infrastructure projects become more intricate, Architectural coatings stand out for their unparalleled ability to cover complex geometries and reach challenging, hard-to-access areas.

Automotive and Commercial Vehicles

In the automotive sector, E-coating has become a staple for protecting the body against corrosion. With the surge in electric vehicles, E-coat technology plays a pivotal role in maintaining the longevity of electric motors and contributing to the overall sustainability of the automobile industry.

Heavy-duty and Construction Equipment

Indispensable in the industrial sector, E-coating ensures the durability of heavy-duty and construction equipment. The corrosion protection it provides enhances the lifespan of machinery, contributing to cost-effective manufacturing processes.

Future Trends and Developments

- Digital Technologies and Artificial Intelligence: The future of E-coating lies in the integration of digital technologies and artificial intelligence. Currently, coating manufacturers at the forefront of innovation are pioneering the use of AI to optimize coating processes, ensuring better color match, faster drying times, and enhanced customer experience.

- Superior Pigments and Coating Development: Developments in pigments, such as pearlescent, silver, and aluminum pigments, are opening new possibilities for decorative paints. With improved functionality and an unmatched aesthetic appeal, these product innovations are minutely crafted to meet the evolving demands of the coatings industry.

- Cool Roof Coatings and UV Radiation: Innovative solutions like cool roof coatings, designed to reflect UV radiation and reduce energy costs, are becoming increasingly popular. These coatings not only provide effective corrosion prevention but also contribute to energy efficiency in commercial and residential buildings.

- Reduced Environmental Impact: E-coatings offer a sustainable and eco-friendly alternative in the coatings industry, addressing key environmental concerns and contributing to a more responsible and resilient industrial landscape.

- Reduced Waste Generation: E-coating is highly efficient in terms of material usage. The process minimizes overspray and excess coating material, reducing overall waste generation. This efficiency aligns with sustainable practices and reduces the environmental impact of coating applications.

- Reduction in Carbon Footprint: The energy-efficient nature of E-coating, coupled with its long-lasting protective properties, contributes to an overall reduction in the carbon footprint associated with coating applications. This aligns with global efforts to mitigate climate change.

Collaborating with E-Coating Experts: Unlocking Key Benefits for Your Business

Collaborating with E-coating experts transcends traditional coating processes, offering a holistic approach to meeting customer, industry, and market demands. As your business navigates the dynamic landscape of the coatings industry, partnering up with E-coating professionals ensures a strategic advantage in terms of quality, performance, and sustainable business growth.

The benefits are clear:

- Easy Access to Cutting-Edge Technology: E-coating experts bring advanced technology and innovative solutions to the table, ensuring that your products benefit from the latest developments in coating materials and application processes.

- Tailored Solutions for Diverse Needs: E-coating experts understand the unique needs of your industry and provide tailored solutions. Whether it’s automotive, industrial machinery, or architectural applications, their expertise ensures that coatings meet specific requirements.

- Enhanced Sustainability and Environmental Performance: The expertise of E-coating professionals extends to sustainable practices. Collaborating with them not only enhances the eco-friendly profile of your products but also aligns with the growing market demand for sustainable solutions.

- Optimized Performance and Durability: E-coating experts excel in optimizing the performance and durability of coated products. Their in-depth knowledge of materials and application processes ensures a protective coating that withstands environmental factors, contributing to the longevity of your products.

- Adaptability to Market Trends: E-coating experts are attuned to market trends, adapting their processes and formulations to meet evolving customer preferences. Collaborating with them positions your business to leverage current and future market opportunities.

The Best Contract Manufacturing Partner

Elevate your business efficiency and focus on strategic growth by partnering with Alpha Contract Manufacturing Group, the leading name in contract manufacturing and outsourced industrial services. From industrial painting solutions such as E-coating and powder coating to metal processing and laser cutting, our team of experts is dedicated to ensuring top-notch quality and precision in every project.

Our wide range of services includes:

- Machining

- Plastics

- Wood processing

- Rubber processing

- Laser cutting

- Metal processing

- Mechanically welded assembly

- Electromechanical

- Industrial painting

- Composites

- Industrial automation robotics

- Assembly manufacturing

Request a quote today and witness the transformation of your manufacturing processes!