The finishing touches on your sheet metal product can make all the difference. The surface finish not only enhances the aesthetics but also plays a crucial role in determining the product’s durability, resistance to corrosion, and overall performance. In this guide, we explore the best surface finishing options to help you make an informed decision based on your specific needs.

The Best Types of Metal Finishes

Powder Coating

Powder coating is a popular and versatile method of applying a protective and decorative finish to various materials, with a primary focus on metals. This process has gained widespread use in industries ranging from automotive and aerospace to appliances and architectural applications, owing to its numerous advantages over traditional finishing methods.

This method involves the application of a dry powder to a substrate using an electrostatic spray gun. The powder particles carry a positive charge, and the substrate is grounded, causing the particles to adhere uniformly to the surface. The coated object is then cured in an oven, where the powder melts and forms a smooth and durable finish.

Advantages

- Durability and Protection: Powder coating creates a robust and resilient finish that provides excellent protection against corrosion, UV rays, chemicals, and other environmental factors. This makes it particularly suitable for outdoor applications and products exposed to harsh conditions.

- Aesthetics and Variety: The powder coating process produces a smooth and even finish, providing a visually appealing surface. Additionally, powder coatings are available in a wide range of colors, textures, and finishes, allowing for customization to meet specific design requirements.

- Environmental Friendliness: Powder coating does not contain solvents, and the overspray can be collected and reused, minimizing waste. Additionally, many powder coatings are free of volatile organic compounds (VOCs), contributing to a cleaner and safer working environment.

- Cost-Effective and Efficient: Powder coating is known for its efficiency in material usage. The overspray can be reclaimed and reused, reducing material waste. The process is also highly automated, leading to increased production efficiency and lower labor costs for large-scale manufacturing.

- Versatility: Powder coating can be applied to a wide variety of metals, including aluminum, steel, and even certain types of plastics. This versatility makes it a preferred choice for diverse industries and applications.

Applications

Powder coating finds extensive use in numerous industries and applications:

- Automotive: Used for coating wheels, frames, and various automotive components, providing both protection and a stylish finish.

- Architectural: Commonly employed for coating aluminum extrusions, doors, windows, and architectural elements due to its durability and aesthetic appeal.

- Outdoor Furniture: Powder coating enhances the longevity and appearance of outdoor furniture by providing a weather-resistant finish.

- Appliances: Widely used in the appliance industry to coat items like refrigerators, washing machines, and ovens, offering protection against corrosion and wear.

- Industrial Equipment: Provides a durable and protective finish for machinery, equipment, and components used in various industrial applications.

E-Coating

Electrocoating, commonly known as e-coating or electrophoretic deposition (EPD), is an advanced method of applying a protective coating to various metal surfaces. This process is widely utilized in industries such as automotive, appliances, and electronics, offering superior corrosion resistance and an even, consistent finish.

E-coating involves the immersion of the object to be coated in a tank filled with a water-based paint emulsion containing charged pigment particles. An electric voltage is applied, causing the charged particles to migrate and deposit onto the metal substrate. This creates a uniform and tightly adhering coating that is cured in an oven to form a durable finish.

Advantages

- Uniform Coating Thickness: E-coating ensures uniform coating thickness across complex shapes and recessed areas, providing consistent protection against corrosion.

- Corrosion Resistance: E-coating excels in corrosion protection, creating a robust barrier against environmental elements. This makes it particularly suitable for automotive components and other products exposed to harsh conditions.

- Penetration and Coverage: The electro-deposition process enables the coating to penetrate recesses and cavities, ensuring comprehensive coverage on all surfaces of the object being coated.

- Environmental Friendliness: E-coating is an environmentally friendly process as it typically involves water-based coatings with lower levels of volatile organic compounds (VOCs) compared to solvent-based coatings.

- Automated and Efficient: The e-coating process is highly automated, contributing to efficiency in large-scale manufacturing. It minimizes overspray, reduces material waste, and ensures consistent coating quality.

Applications

E-coating is widely used across various industries for different applications:

- Automotive: Commonly used for coating automotive bodies, frames, and components to provide corrosion resistance and enhance the longevity of vehicles.

- Appliances: Applied to metal parts of appliances like dishwashers, refrigerators, and washing machines, offering both corrosion protection and an aesthetically pleasing finish.

- Electronics: Used for coating electronic components, chassis, and enclosures to protect against corrosion and environmental exposure.

- Hardware and Fasteners: E-coating is effective in providing corrosion resistance for screws, bolts, and other hardware components.

- Furniture: Utilized in the coating of metal furniture frames and components to enhance durability and protect against outdoor elements.

Liquid Industrial Paint

Liquid industrial paint, a traditional yet enduring method of surface coating, remains a staple in various industries for its versatility in providing both protective and decorative finishes. This coating method is widely employed across sectors such as manufacturing, construction, and infrastructure, offering a customizable solution for a broad range of applications.

This type of paint is applied as a liquid solution containing pigments, binders, solvents, and additives. The application methods include brushing, rolling, spraying, or dipping, depending on the object’s size, shape, and the desired finish. The coated object is then left to dry and cure, forming a protective and visually appealing layer.

Advantages

- Versatility in Substrate Compatibility: Liquid paint can adhere to various substrates, including metals, plastics, wood, and concrete, providing versatility in application across different materials.

- Customizable Finishes: Liquid paint offers a wide range of colors, finishes, and textures, allowing for customization to meet specific aesthetic requirements. This makes it a preferred choice for decorative applications.

- Ease of Application: Liquid paint is relatively easy to apply using conventional methods like brushing, rolling, or spraying. It is adaptable to both small-scale and large-scale manufacturing processes.

- Field Repairability: In the event of damage or wear, liquid-painted surfaces can be easily touched up or repainted on-site, facilitating field repairability without the need for specialized equipment.

- Cost-Effectiveness: Liquid industrial paint is often considered cost-effective, particularly for small to medium-sized production runs. The materials are readily available, and the application equipment is relatively straightforward.

Applications

Liquid industrial paint finds widespread use in a variety of applications across different industries:

- Construction: Applied to structural steel, pipelines, and concrete surfaces for corrosion protection and aesthetic enhancement.

- Automotive: Used for coating vehicle bodies, components, and parts to provide both protection and visual appeal.

- Machinery and Equipment: Applied to industrial machinery, equipment, and tools for corrosion resistance and a professional finish.

- Infrastructure: Utilized in the coating of bridges, railings, and other infrastructure elements for protection against the elements and environmental exposure.

- Furniture and Fixtures: Liquid paint enhances the appearance and durability of furniture, fixtures, and architectural elements.

Liquid industrial painting services

Factors to Consider Across Finishing Options

Corrosion Resistance

Corrosion resistance refers to a material’s ability to withstand and resist deterioration or degradation caused by various environmental factors, particularly chemical reactions with its surroundings. In the context of sheet metal products, corrosion resistance is a critical consideration, particularly when the products are intended for use in demanding environments, such as aerospace applications.

Electrical Conductivity

Electrical conductivity is a measure of a material’s ability to conduct an electric current. It indicates how easily electrons can flow through a substance when a voltage is applied across it. Electrical conductivity is a fundamental property that plays a crucial role in various applications, from electronic components to everyday conductors.

When considering the surface finish for sheet metal products, the evaluation of electrical conductivity is crucial, particularly for products that require efficient conduction of electric current. The electrical properties of the finished product can significantly impact its functionality, especially in applications where electrical conductivity is a critical requirement.

Surface Roughness

Surface roughness is a critical aspect of sheet metal finishing, influencing both the aesthetics and functional properties of the final product. Different finishing methods yield varying degrees of surface roughness, and understanding this aspect is crucial to ensure that the finished product aligns with the specified requirements.

Cost and Production Method

Cost considerations play a pivotal role in the selection of a surface finishing option for sheet metal products. Understanding the overall costs, including labor costs and production efficiency, associated with each finishing method is essential to make informed decisions that align with budget constraints and manufacturing goals.

Key Factors to Consider to Choose a Material for Sheet Metal Parts

How to Choose the Right Surface Finish

Consider the specific requirements of your sheet metal product, including its intended application, environmental conditions, and desired appearance. By understanding the properties of different finishes and considering the specific needs of your application, you can ensure the production of a high-quality and durable finished product.

Consult with Professionals

Making the right decision among surface finishing methods is crucial for your project’s success. By consulting with contract manufacturing experts, you can benefit from their knowledge and insights to guide you in selecting the optimal surface finishing method.

Revamp Your Manufacturing Process with Alpha Contract Manufacturing Group

Alpha Contract Manufacturing Group is the ideal partner in industrial contract manufacturing. We offer a comprehensive range of industrial services, delivering professional knowledge, strategic insights, and cutting-edge technology without the need for direct investments.

Explore Our Contract Manufacturing Services

- Industrial Painting: Find the right partner for precise industrial paint application. We offer turnkey industrial painting services, understanding that coating specifications depend on application surface properties, whether for powder or liquid paint.

- Powder Coating: Rely on us as your trusted powder coating service provider. With years of industry experience and state-of-the-art equipment, our specialists ensure the efficient coating of metal parts of all kinds.

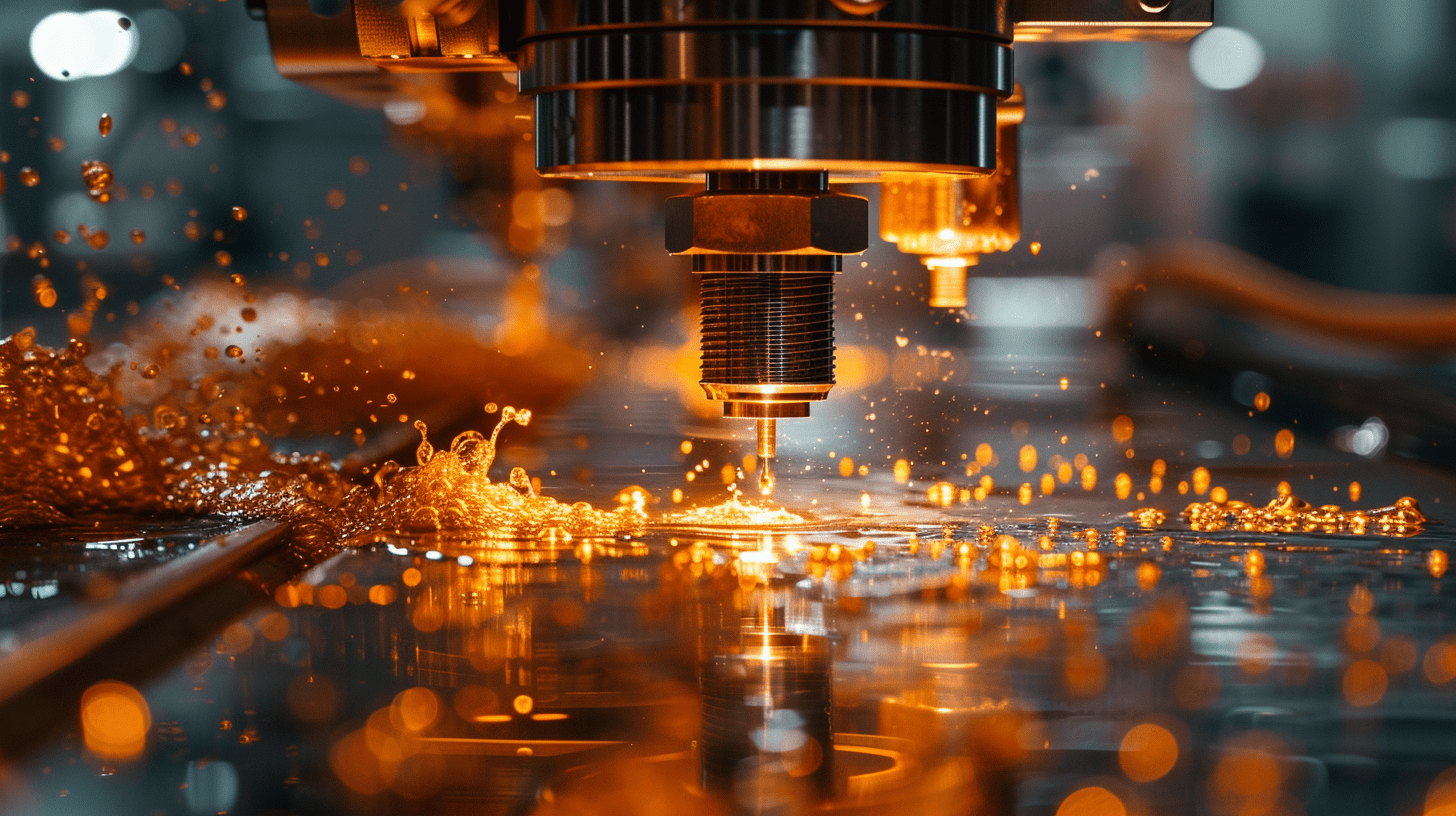

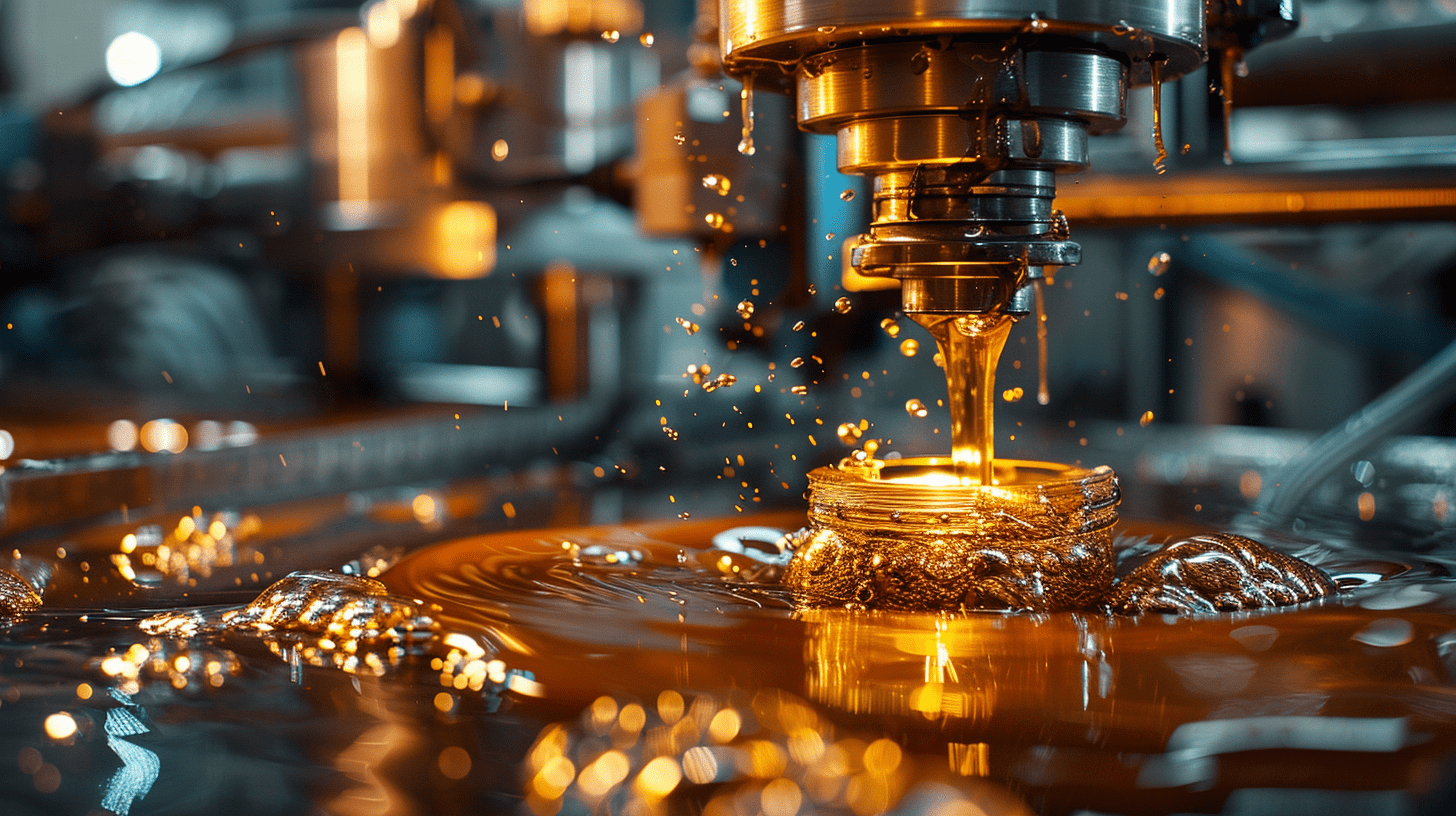

- Laser and Water Jet Cutting: Experience precision with our laser and water jet cutting services. We use cutting-edge technology to deliver the highest quality cutting services for manufacturing businesses across all industries.

- Industrial Automation: Optimize your production processes and performance with our automation and robotization services. Our state-of-the-art equipment is designed to enhance efficiency in your factories.

- Wood Processing, Industrial Rubber, and more: We offer turnkey solutions for wood processing, industrial rubber manufacturing, metal processing, electromechanics, and other specialized areas. Our expertise spans small to large-scale projects, ensuring quality at every stage.

Get in touch for a quote and discover how our industrial contract manufacturing services can enhance your production capabilities.

Frequently Asked Questions

Why is stainless steel a preferred choice for surface finishing?

Stainless steel is favored for its inherent corrosion-resistant properties, making it an excellent material for various applications. It offers durability and a sleek aesthetic.

What are the benefits of a smooth finish in surface coatings?

A smooth finish not only enhances the visual appeal of the product for aesthetic reasons but also contributes to improved cleanability and reduces friction, making it an ideal choice for applications where a sleek appearance and easy maintenance are crucial.

Is a rough surface ever desirable for specific applications?

In some cases, a rough surface may be intentionally chosen for functional or aesthetic reasons. We work closely with clients to understand their specific requirements, offering solutions that balance both the desired finish and the practical needs of the application.

How can surface finishing benefit product designers?

Surface finishing options offer product designers the freedom to choose coatings that align with their design vision. Whether it’s achieving a smooth, polished look or incorporating corrosion-resistant features, designers can optimize the aesthetics and functionality of their creations.

What considerations should be made for abrasive metals in surface finishing?

For abrasive metals like mild steel, we take special care in selecting appropriate finishing methods. This ensures not only an aesthetically pleasing result but also addresses the challenges posed by abrasive materials to achieve a durable and resilient finish.

SEO GLOSSARY›