Industrial Contract Manufacturing Group (ICMG) is committed to being the perfect plastic manufacturing partner for businesses. Our team of experts has years of experience in the industry, and we use state-of-the-art equipment and facilities to produce high-quality plastic products for your business.

As plastic manufacturers and leaders in the plastic industry, ICMG is able to offer a level of personal service and attention to detail that larger, out-of-state companies simply cannot match. Moreover, as a plastic parts manufacturer, we understand the unique needs of businesses in our community, and we are dedicated to helping you find the perfect plastic solution for your needs.

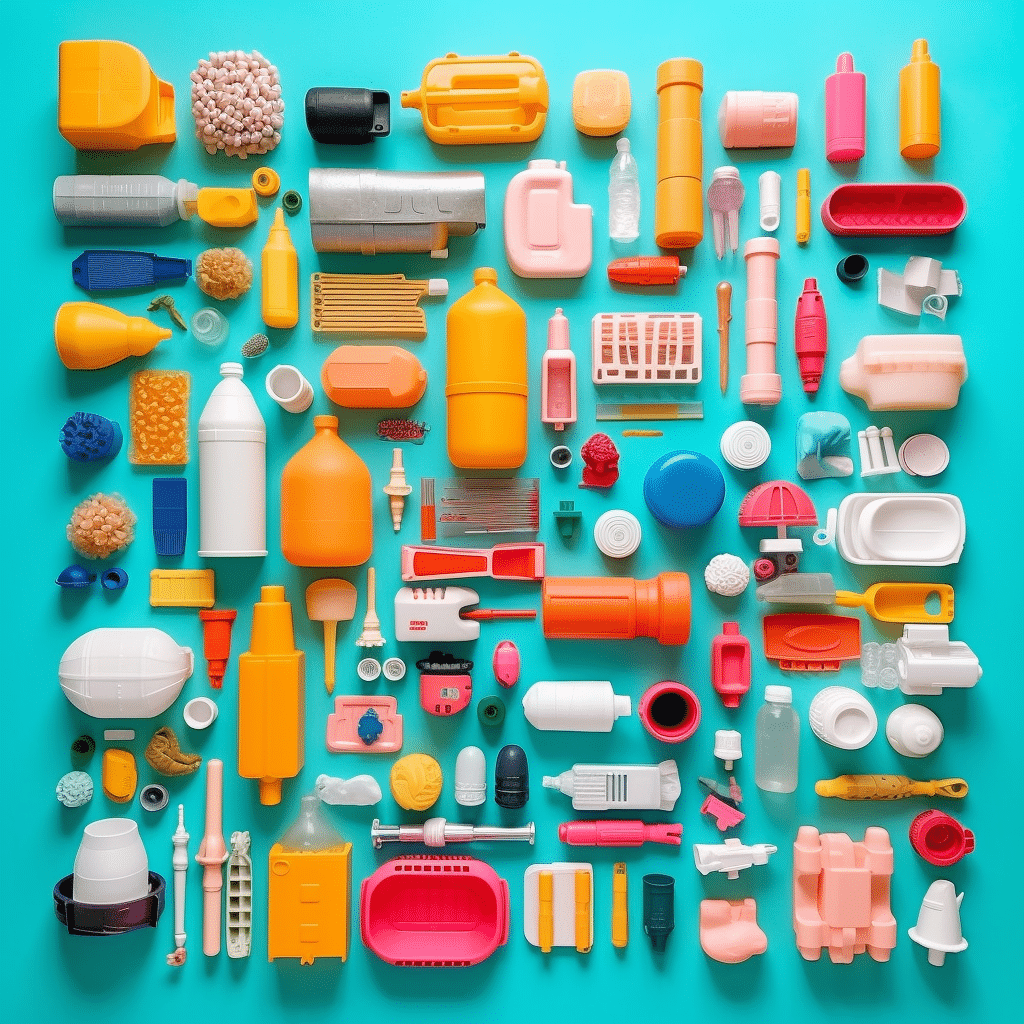

Industrial Contract Manufacturing Group, as a plastic company, offers a range of services to meet the diverse needs of our customers. Our team is dedicated to providing high-quality, custom plastic manufacturing solutions that are tailored to your specific requirements thanks to our ability to accommodate a wide range of plastic materials and finishes.

Whether you need a specific color, texture, or performance characteristic, we have the expertise and resources to deliver the perfect product for your needs.

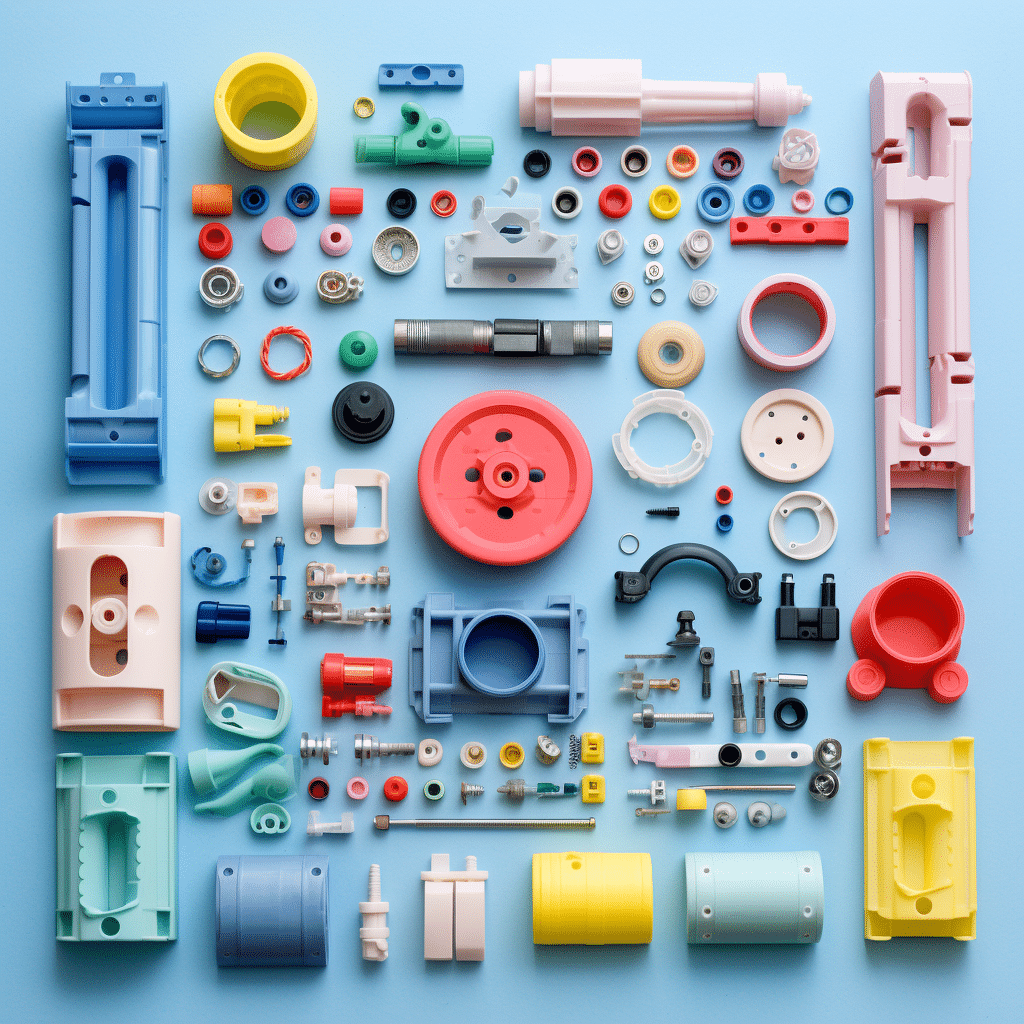

Plastic molding is a manufacturing process used to create plastic parts and components by injecting heated, melted plastic into a mold. This method of manufacturing is commonly used in the production of a wide variety of plastic parts and components, from consumer products such as toys, to industrial parts such as machine components. Plastic molding is a fast, accurate and cost-effective way to produce high-quality plastic parts that can be used for a variety of purposes.

Looking for a reliable and cost-effective way to assemble components made of plastic? ICMG offers a plastic component assembly service, allowing you to save time, money, and resources. Not only do our services provide precise and consistent assembly results, they also offer quick turnaround times and can often provide custom assemblies tailored to your exact specifications.

In addition to mass production, we also offer prototyping and low-volume production services. This is a great option for businesses that are looking to test out a new product or design before committing to a larger run. Our team is happy to work with you to find the best solution for your needs.

No matter what your plastic manufacturing needs may be, Industrial Contract Manufacturing Group is here to help. Contact us today to learn more about our services and to request a quote.

No matter what your plastic manufacturing needs may be, Industrial Contract Manufacturing Group is here to help. Contact us today to learn more about our services and to request a quote.

When it comes to choosing a plastic manufacturing partner, there are many factors to consider. Here are a few reasons why ICMG stands out from the competition:

Our team has years of experience in the industry and a deep understanding of all aspects of plastic manufacturing. From design and prototyping to mass production and fulfillment, we have the skills and expertise to deliver top-quality products for your business.

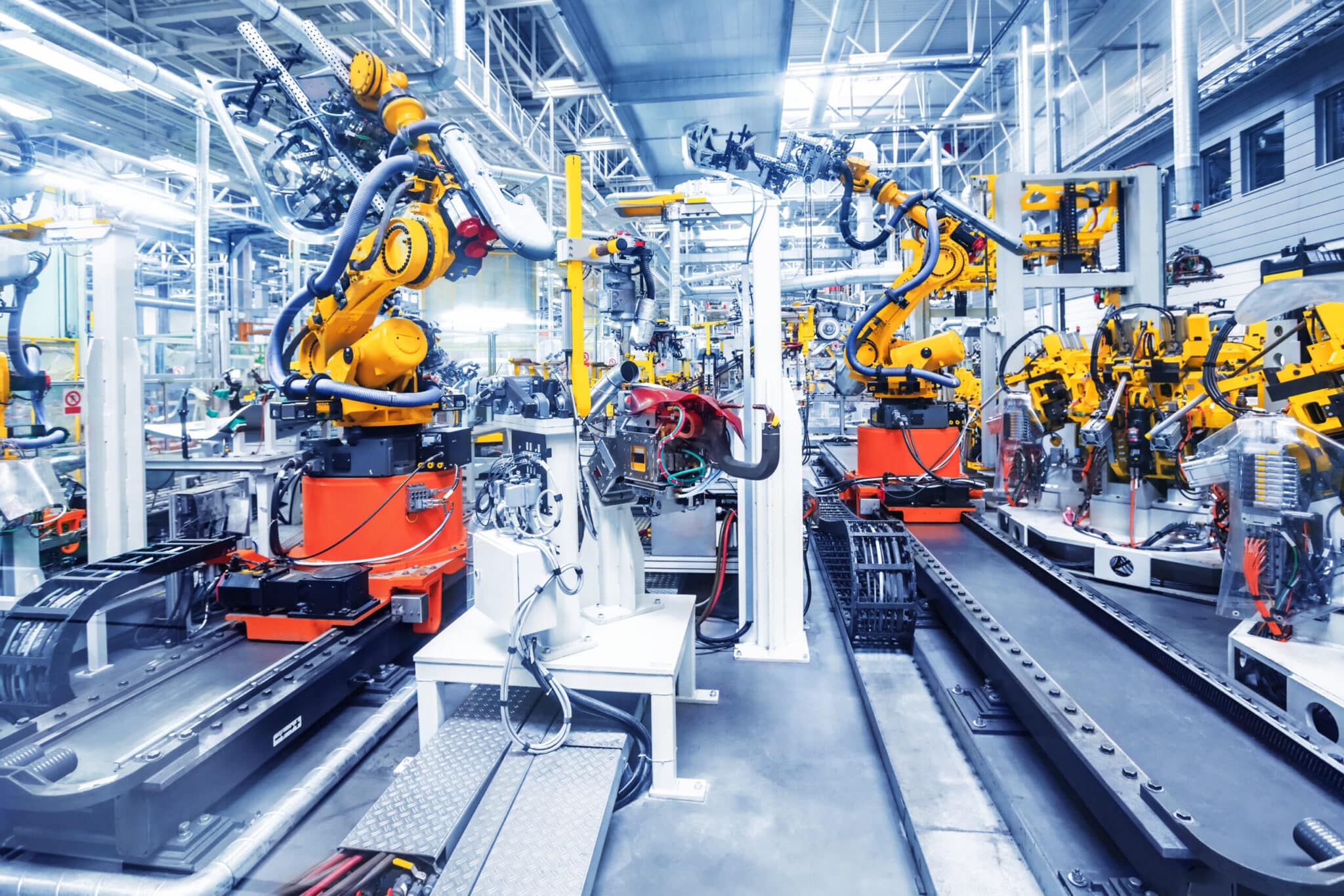

We use the latest equipment and technologies to produce high-quality plastic products. Our facilities are clean, well-maintained, and equipped with everything we need to deliver top-notch products to our customers.

At ICMG, we are committed to operating in a responsible and sustainable manner. We use eco-friendly materials and processes whenever possible, and we strive to reduce our impact on the environment.

When you choose ICMG as your plastic manufacturing partner, you can feel confident that you are working with a team that is dedicated to delivering the best products and services possible.

No matter what your plastic manufacturing needs may be, Industrial Contract Manufacturing Group is here to help. Contact us today to learn more about our services and to request a quote.

In addition to our top-notch manufacturing capabilities, we also offer a wide variety of plastic materials and finishes to choose from. Our team is happy to work with you to find the best fit for your specific application.

We pride ourselves on our responsible and sustainable manufacturing practices. We are committed to reducing our impact on the environment and providing our customers with products they can feel good about using.

We have a well-established process for delivering high-quality plastic finished products (such as synthetic fibers) to our customers. Here’s an overview of our process:

The first step in our process is to work closely with our customers to understand their needs and goals. We offer consultation and design support to help you refine your ideas and create a plan for your custom plastic high-quality product.

Once we have a clear understanding of your requirements, we can move on to the prototyping and testing phase. We use rapid prototyping techniques to quickly produce prototypes of your product, which can then be tested to ensure that they meet your specifications.

Once the prototype has been approved, we can move on to mass production. We have state-of-the-art equipment and facilities that allow us to produce high-quality plastic products at scale. We also offer fulfillment services to ensure that your products are delivered to you in a timely and efficient manner.

Throughout the process, our team is here to provide support and guidance to ensure that your custom plastic product is exactly what you need.

Faced with new requirements in the market and the high level of competition in the manufacturing sector, more and more manufacturing firms are turning to subcontracting in order to lower their production costs, increase their performance or meet greater demand. In this context, the first challenge is generally related to the choice of one’s new partners. And it’s not an easy task to identify subcontractors who actually meet all your particular expectations. The best option is to turn to a cluster of firms specialized in industrial subcontracting.

Whatever your special needs are, we do everything to guarantee your satisfaction.

We apply these values when it comes time to choose our partners and begin each of our projects to ensure that every client also benefits.

Plastic manufacturing is the process of forming plastic materials into products and components of various shapes and sizes through a variety of methods, such as injection molding, extrusion, blow molding, and rotational molding. It is used to create a wide range of products, from medical equipment to toys.

Here is an overview of the wide array of industries we serve:

ICMG works with a wide range of materials, including polyethylene, polymer, polypropylene, polycarbonate, ABS, and more. We can accommodate a variety of plastic materials and finishes to meet the specific needs of your project.

Absolutely! We offer prototyping and low-volume production services to help you bring your ideas to life. This is a great option for businesses that are looking to test out a new product or design before committing to a larger run.

Yes, we offer custom manufacturing services to meet the unique needs of our customers. Our team of experts is happy to work with you to design and produce a custom plastic product that meets your specific requirements.

Yes, we have experience working with a wide range of industries, including aerospace, medical, automotive, consumer goods, and more. Our team has the expertise and resources to produce high-quality plastic products for a variety of industries.

At ICMG, we have strict quality control processes in place to ensure that our products meet the highest standards. We use state-of-the-art equipment and facilities, and our team is dedicated to delivering top-quality products to our customers.

Yes, we offer fulfillment services to ensure that your products are delivered to you in a timely and efficient manner. This includes packaging, labeling, and shipping services.

We stand behind the quality of our products and offer a warranty or guarantee for all of our products. If you experience any issues with a product that you have purchased from us, please don’t hesitate to contact us to discuss your options.