Turnkey manufacturing has become a go-to solution for businesses seeking a streamlined and efficient manufacturing process. By outsourcing production to a specialized manufacturer, companies can save costs, speed up time-to-market, and ensure higher product quality. This approach allows businesses to focus on other crucial aspects while experts handle the manufacturing process.

However, it’s important to carefully select the right turnkey solutions provider to overcome potential limitations and disruptions in the supply chain. In this comprehensive guide, we explore the power of turnkey manufacturing as a seamless solution for optimizing the manufacturing process and bringing products to market efficiently.

Key Takeaways

- Turnkey manufacturing provides an end-to-end, hassle-free solution for businesses.

- It reduces lead times and communication costs compared to contract manufacturing.

- Turnkey manufacturing allows businesses to focus on other critical aspects and utilize the expertise and resources of specialized manufacturers.

- Selecting the right turnkey manufacturing solutions provider is crucial for the success of a project.

What Is Turnkey Manufacturing?

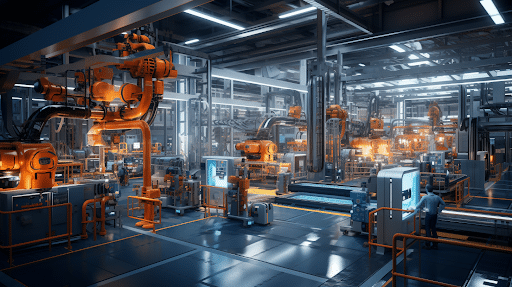

Turnkey manufacturing represents a custom manufacturing approach to outsourcing production. When companies collaborate with turnkey manufacturers, they entrust them with the entire manufacturing process, from conception to final product delivery. These specialized contract manufacturers, known as turnkey contract manufacturers, offer turnkey manufacturing services that cover all aspects, including sourcing materials, designing, manufacturing, and quality control.

This comprehensive approach ensures a consistent level of quality throughout the production cycle, as turnkey contract manufacturers manage and coordinate various manufacturing departments seamlessly. It allows businesses to streamline their operations, reduce costs, and focus on their core competencies while relying on the expertise of turnkey manufacturers to handle the intricacies of production.

Contract manufacturing services

10 Stages of Turnkey Manufacturing

Turnkey manufacturing typically involves several key stages of production:

- Project Initiation: This stage includes defining project objectives, setting expectations, and establishing key performance indicators (KPIs). This is when the project managers set their expectations.

- Design and Engineering: Product design for manufacturing and development takes place, with a focus on creating detailed plans, prototypes, and specifications.

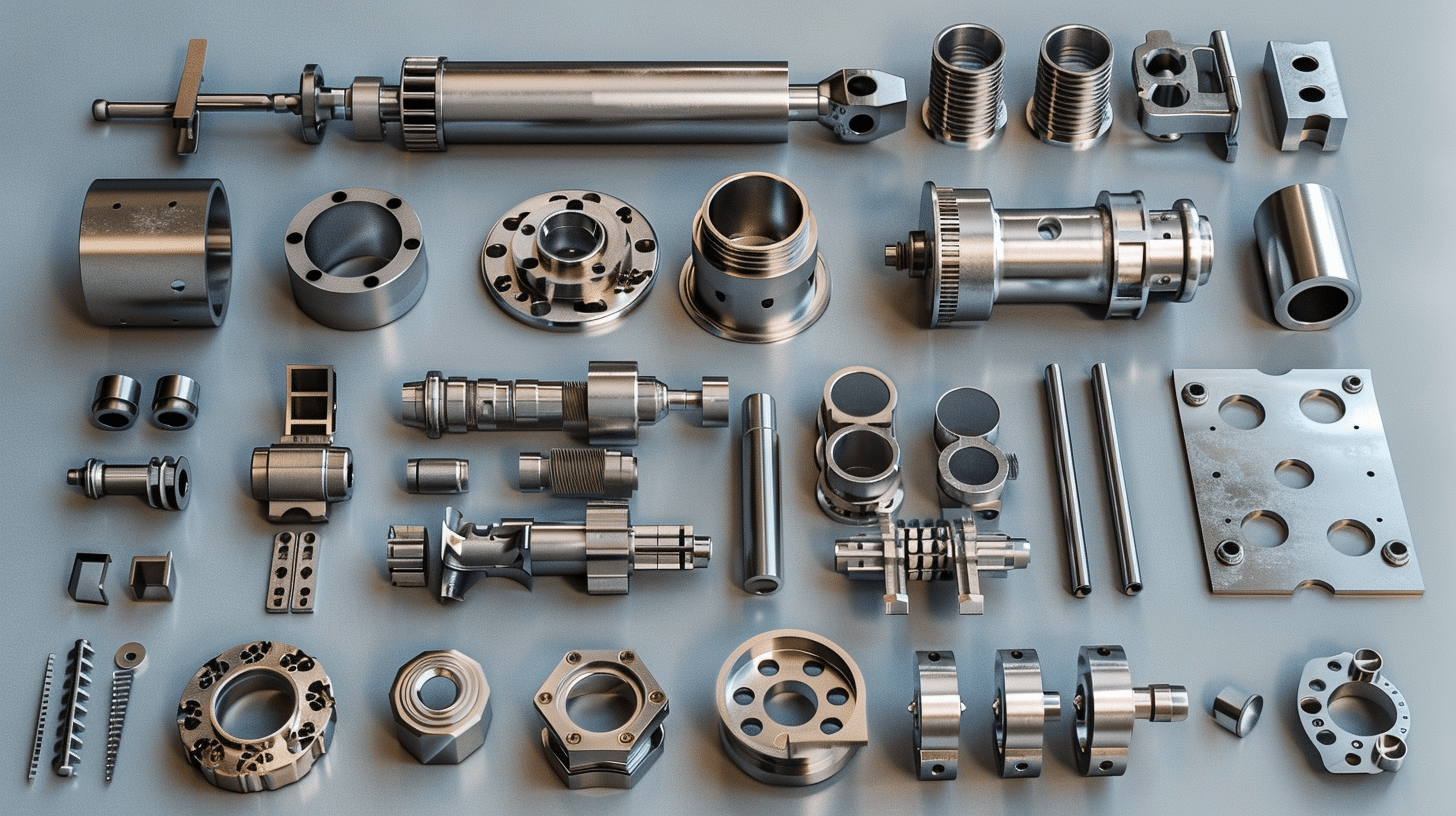

- Sourcing and Procurement: Vendor selection for procuring raw materials, components, and equipment necessary for production, often leveraging cost-effective supply chain strategies.

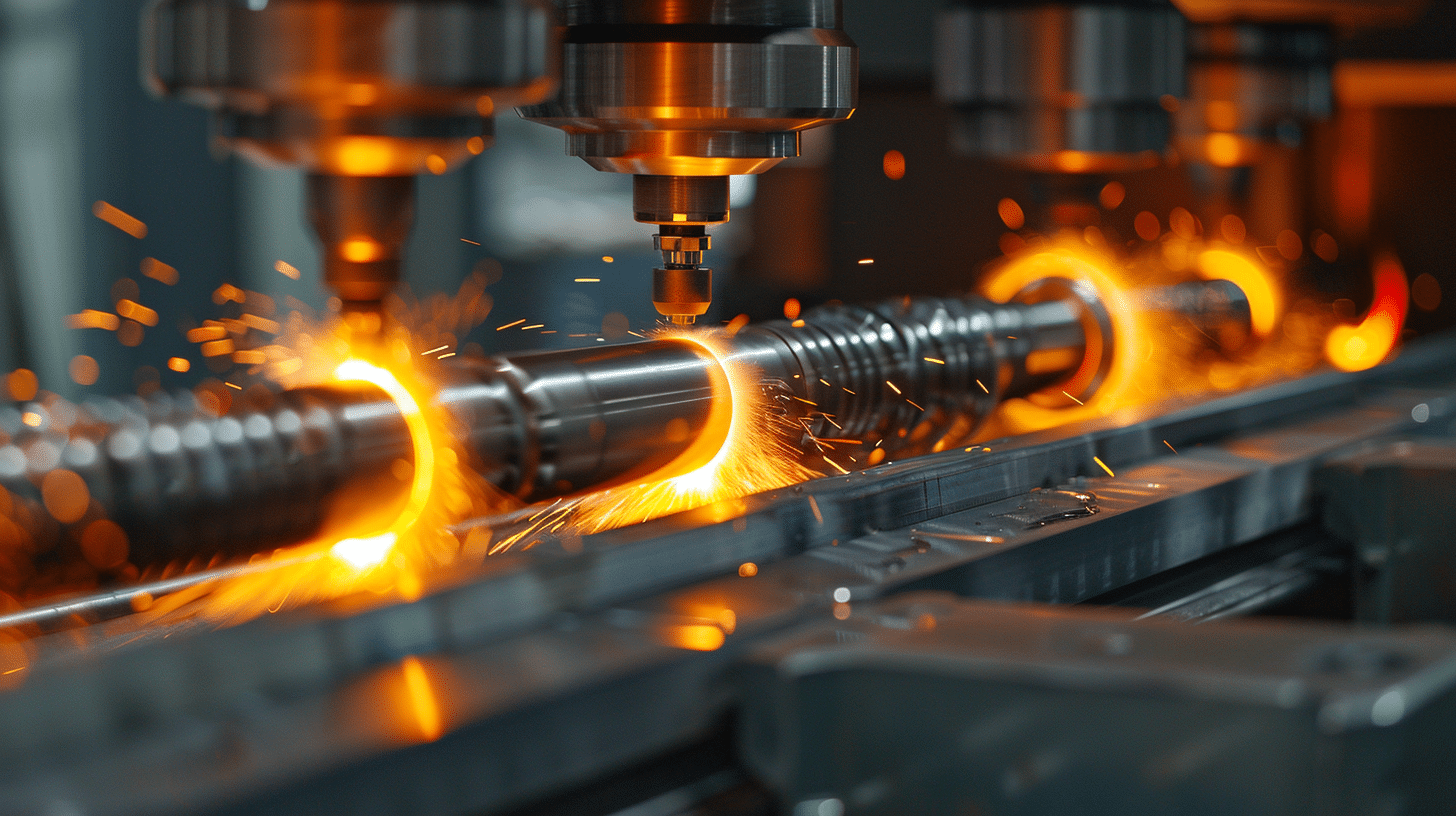

- Manufacturing and Assembly: The actual production of the product, where raw materials are transformed into finished goods, often in compliance with strict quality control measures.

- Quality Control and Assurance: Rigorous testing and inspections are conducted to ensure that the final product meets quality standards and specifications.

- Packaging and Labeling: Preparing the product for distribution, including packaging, labeling, and, if necessary, customization.

- Logistics and Distribution: Managing the logistics of shipping and distributing the finished products to their intended destinations.

- Installation and Commissioning: In some cases, especially in industries like construction or machinery manufacturing, the turnkey provider may be responsible for installing and commissioning the product on-site.

- Maintenance and Support: Ongoing support and maintenance services may be provided to ensure the product’s optimal performance throughout its lifecycle.

- Project Completion and Handover: Final documentation, finishing services, training, and project handover to the client, along with any necessary warranties or guarantees.

These stages create a streamlined process but might vary depending on the specific project, industry, and client requirements, but they provide a general framework for understanding the typical phases of turnkey manufacturing.

Benefits of Turnkey Manufacturing

The benefits of turnkey manufacturing span the entire spectrum of product development and production stages. Whether it’s streamlining the entire turnkey project or accommodating a wide variety of manufacturing needs, this approach offers a comprehensive solution that optimizes efficiency and quality.

Efficiency

Turnkey manufacturing offers remarkable efficiency benefits within the manufacturing industry. By entrusting the turnkey provider with the entire process, companies experience a streamlined and cohesive approach that eliminates the intricacies of dealing with multiple suppliers or stages.

This turnkey process optimizes the manufacturing landscape, minimizing lead times and production time, reducing operational complexities, and enhancing overall productivity, making it an advantageous choice for companies seeking a seamless and efficient production solution whilst still producing high-quality finished products.

Cost Savings

One significant benefit of turnkey manufacturing is the cost savings it offers. By utilizing a turnkey service, companies can often realize substantial cost benefits. This is due to the turnkey provider’s ability to efficiently manage the entire production process, optimize resource allocation, and leverage economies of scale.

Moreover, turnkey contracts typically offer price certainty, reducing the risk of unexpected cost overruns and providing businesses with a clear understanding of their investment requirements. Overall, turnkey manufacturing presents a compelling option for companies looking to achieve reduced costs and enhanced financial predictability in their production endeavors.

Specialized Expertise

Turnkey contract manufacturing brings invaluable expertise to the table. From product design to manufacturing facilities, turnkey providers possess a deep understanding of various aspects of manufacturing. Their proficiency extends to sourcing components, ensuring quality throughout the design phase, and optimizing production processes. This wealth of experience translates into the delivery of high-quality products, making turnkey manufacturing a dependable choice for businesses seeking not only cost-effective solutions but also the assurance of a well-crafted end result.

What should I consider when choosing a contract manufacturer?

Industries That Utilize Turnkey Manufacturing

Several industries benefit from turnkey manufacturing services due to the efficiency, cost-effectiveness, and expertise it offers. These industries include:

- Electronics: Turnkey manufacturing is widely used for the production of electronic devices, such as smartphones, tablets, and consumer electronics, where precision and quality are paramount.

- Automotive: Automotive manufacturers employ turnkey manufacturing for various vehicle components and assemblies, ensuring consistent quality and efficient production.

- Aerospace: The aerospace industry relies on turnkey manufacturing for complex and critical components, meeting strict safety and performance standards.

- Pharmaceuticals: Pharmaceutical companies utilize turnkey manufacturing for drug formulation, packaging, and quality control, ensuring compliance with regulatory requirements.

- Medical Companies: Manufacturers of medical devices, such as diagnostic equipment and implantable devices, rely on turnkey services to ensure precision and compliance with medical regulations.

Turnkey Contract Manufacturing Services

If you believe your business could leverage the advantages of a contract manufacturing partnership, Alpha Contract Manufacturing Group is at your service. Our extensive range of manufacturing services is tailored to accommodate the unique requirements of various industries. Our service portfolio encompasses wood processing, assembly manufacturing, and electronics manufacturing. Committed to delivering excellence, efficiency, and personalized solutions, we stand as a reliable ally for enterprises in pursuit of top-tier, cost-efficient manufacturing solutions.

Frequently Asked Questions

Consider factors such as industry expertise, track record, capacity, location, cost-effectiveness, and their ability to meet your specific project requirements.

Yes, it can be a concern. Contracts often include provisions for safeguarding intellectual property, such as confidentiality agreements and ownership rights.

Industries such as electronics, automotive, aerospace, pharmaceuticals, and consumer goods frequently leverage turnkey manufacturing for various production needs.