Have you ever heard of contract manufacturing? It is a unique way to handle the manufacturing process of products or services without actually owning the factories and equipment used in production. In this article, we explain what contract manufacturing is, how it works, and why it can be beneficial for businesses.

What Is Contract Manufacturing?

Contract manufacturing is an arrangement between two parties where one party, the contract manufacturer, agrees to produce goods and services for another based on a contractual agreement. This allows companies to save money on production while still getting the quality products they need.

The idea behind contract manufacturing is simple: instead of buying all the necessary resources to manufacture items yourself, you outsource that work to another company. This means hiring manufacturers who specialize in producing certain types of goods at lower costs than if you had manufactured them on your own.

A contract manufacturer can provide various types of services including raw material procurement, product design, assembly of components, cost savings through economies of scale, production process management, private label manufacturing, and much more. Contract manufacturers also have their own proprietary intellectual property which they use to optimize the production process and create innovative solutions for clients.

When companies outsource certain parts of the production process to a contract manufacturer, they gain additional flexibility while meeting customer demand, lower costs associated with having an internal production unit, and create a more efficient supply chain. This makes entering new markets easier and faster than when done entirely in-house.

Types Of Contract Manufacturing

Contract manufacturing is often used to produce all kinds of goods, from pharmaceuticals and medical devices to electronic products and automobile components. Through this business strategy, manufacturing companies can handle production following international standards for quality control.

The term contract manufacturing covers different types of outsourcing arrangements such as short-term contracts or long-term partnerships between producers and external suppliers. Short-term contracts are beneficial when demand is expected to increase in a particular season while long-term agreements provide stability during times of unpredictable changes in market conditions. The scope and length of these contracts determine the degree of control that the producer has over their production process, allowing them to manage their budget more effectively.

This type of manufacturing involves organizations that produce components, sub-assemblies, assemblies, and finished products according to customer specifications. It can also include product design and engineering services as well as legal contract development.

Examples of contract manufacturing include:

- Plastics manufacturing

- Wood processing

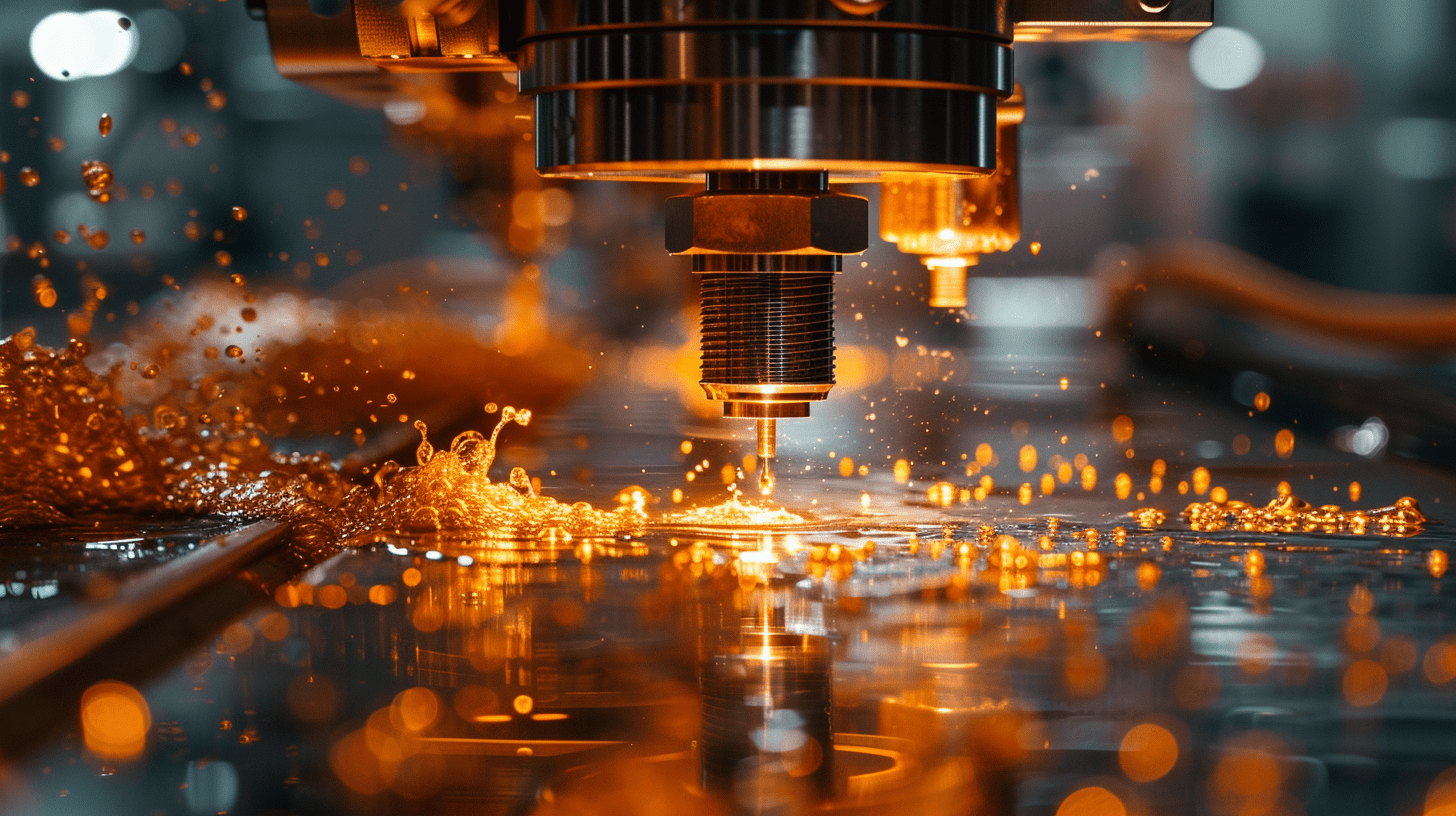

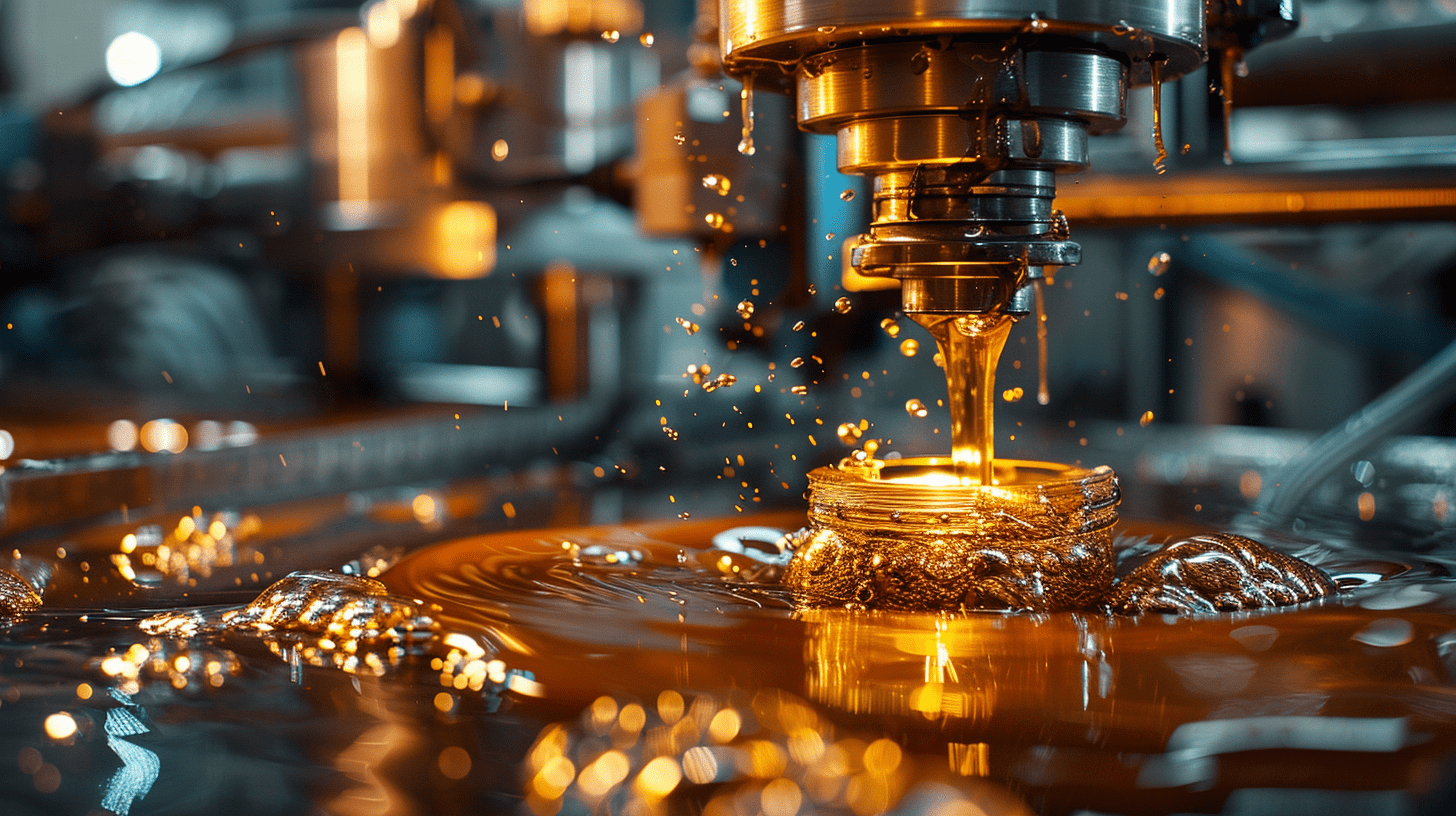

- Water jet cutting

- Rubber processing

- Metal processing

- Mechanically welded assembly

- Electromechanical services

- Liquid industrial coating services

- Composite manufacturing

- Industrial automation

Why Is Contract Manufacturing Important?

Contract manufacturing is an important part of many industries because it provides businesses with the ability to outsource the production process. This means business owners can gain access to specialized resources and complete control over their products without having to buy expensive machinery or heavy equipment.

Contract manufacturers provide companies with access to a wide range of services and expertise, allowing them to focus solely on product development rather than worrying about other aspects of the production process such as quality control testing and production efficiency.

Additionally, contract manufacturing allows companies to adjust quickly when changes occur in customer demands or supply chain costs, making it easier for them to stay competitive in today’s market. This makes this business practice particularly beneficial for those operating within the food industry or electronics industry who may lack the internal resources needed to rapidly adapt to customer trends on their own.

Overall, contract manufacturing offers numerous advantages for both businesses and manufacturers by streamlining processes and reducing risks associated with producing goods while ensuring high-quality standards are met. By partnering with a reliable contractor, businesses can have peace of mind knowing that their product will turn out exactly as expected without any last-minute surprises or delays caused by unexpected issues during production.

What Are The Benefits Of Contract Manufacturing?

The greatest benefit of manufacturing contracts is their ability to provide quality management and oversight. They Help ensure that each step meets industry standards while also freeing up resources for other areas within your own company, such as marketing or research and development.

Reliable contract manufacturers allow organizations to access specialist expertise and technology not available internally. By leveraging contractual agreements with experienced third-party suppliers, businesses can quickly scale operations while still maintaining control over their supply chain. This approach helps manage risks associated with large investments in equipment procurement and long lead times on new product developments.

Contract manufacturing also offers flexibility when it comes to choosing which materials and processes are used during production. Companies have more control over their product’s design and specifications by working with an experienced manufacturer who understands their needs and goals. Additionally, since these manufacturers often have access to new technologies and techniques, companies can benefit from faster turnaround times as well as higher-quality products.

Scalability Opportunities

Contract manufacturing offers several opportunities for scalability. Contract manufacturers allow businesses to take advantage of economies of scale, as they can benefit from lower labor costs and other cost reductions associated with large-scale production demands over a period of time.

In addition, contract manufacturing enables producers to maximize the use of their own internal resources by leveraging the expertise of third-party companies that specialize in certain aspects related to product design and development. This makes it easier for businesses to access specialized capabilities without having to invest heavily in personnel training or establishing costly infrastructure setups.

Technical Expertise

Technical expertise from reputable contract manufacturers provides potential customers with quality assurance in terms of product assembly, material costs, and manufacturing processes. The best contract manufacturers can offer engineering expertise and the latest industrial equipment to produce complex products cost-effectively.

Tailored solutions

In addition to providing key services such as design engineering, component sourcing, assembly line management, testing and validation, and onsite support, many contract manufacturers offer customer-specific solutions tailored specifically to meet the exact requirements of each project.

This means that businesses can benefit from more efficient production processes as well as improved product quality. Furthermore, due to their extensive experience in the industry, these professionals have developed best practices that help ensure that clients receive reliable results every time.

Lower Overhead

Contract manufacturing is an effective way to manage overhead costs without sacrificing quality or performance. This makes it an attractive option for many organizations looking to optimize operations without breaking the bank.

Experienced contract manufacturers understand the importance of quality control when working alongside pharmaceutical companies and other sophisticated industries. This ensures that all items meet industry standards before being shipped out. Moreover, you don’t have to worry about spending too much time and money monitoring your operations.

Contract manufacturers also provide support services like warehousing/distribution centers which further help reduce their operating expenses while increasing efficiency and maximizing profits. They leverage best practices when dealing with materials handling, packaging, and labeling processes and adhere to strict safety regulations.

Resource Savings

Maintaining solid business relationships with contract manufacturers is a great way to save resources in your business. Not only does it cut down on overhead costs associated with running a manufacturing business, but it also allows you to gain access to valuable metal fabrication services and other services at reduced costs.

By outsourcing work to companies with specialized knowledge and equipment, businesses can save time and money on their projects while still receiving quality results. Additionally, it allows them to focus more resources on other aspects of their operations such as marketing or new product development. In addition, choosing a reputable contract manufacturer can help streamline workflows for those involved in product development. This ensures businesses get the most out of their investments while still providing high-quality products quickly.

Faster Time To Market

Achieving faster time to market is one of the primary advantages offered by a contract manufacturing business model. By outsourcing production, businesses can significantly reduce their overall manufacturing time and save hundreds of thousands of dollars in the process.

Fast delivery times are another big benefit associated with contract manufacturing services. Contract manufacturing organizations can consistently provide quality on-time deliveries, so businesses don’t need to be concerned about late arrivals or other issues that might delay shipping times.

Higher Quality Products

The best contract manufacturers have access to highly efficient production facilities and quality control measures that help ensure products meet specific product specifications while also ensuring regulatory requirements are met. This means companies don’t have to worry about low-quality products reaching consumers.

The production processes are strictly monitored with advanced technology to ensure all components are up to standards. Quality assurance teams perform tests throughout the various stages of production from raw material inspection to final assembly testing according to industry guidelines. By outsourcing certain aspects of production or even complete projects, organizations can focus on core activities instead of worrying about operational details such as sourcing raw materials or managing inventory levels.

Manufacturing Services

Contract manufacturing is a great way to bring quality products to market quickly and cost-effectively. It offers companies the chance to scale up production with ease and access technical expertise that would be otherwise unavailable. By partnering up with Alpha Contract, you’ll be empowered to produce high-quality goods without having to invest heavily in personnel or equipment.

Our services can prove integral for any company looking to stay competitive and maximize its potential profits. Working alongside Alpha Contract gives businesses access to specialized expertise and quality control procedures. Thanks to our vast body of experience in both large-scale and small-scale production, our clients have substantial flexibility when deciding what kind of output they want to achieve.