Contract manufacturing has become a popular choice for businesses because it enables them to outsource parts of their production process without taking on any additional costs or risks associated with doing so. Companies can benefit from reduced costs while still maintaining control over quality assurance and product specifications. In this article, we explore some real-world examples of industries that substantially benefit from this practice.

What Is Contract Manufacturing?

Contract manufacturing is a process in which an outside company manufactures products for another organization. Experienced contract manufacturers are able to handle the entire manufacturing process, from initial product design and raw material sourcing to performing quality control operations.

There are several types of contract manufacturing agreements, from one-time projects to long-term partnerships between organizations. Companies may opt for either full-service contract manufacturing (which covers all aspects of production including R&D, engineering, and supply chain management) or partial services like assembly and packaging alone.

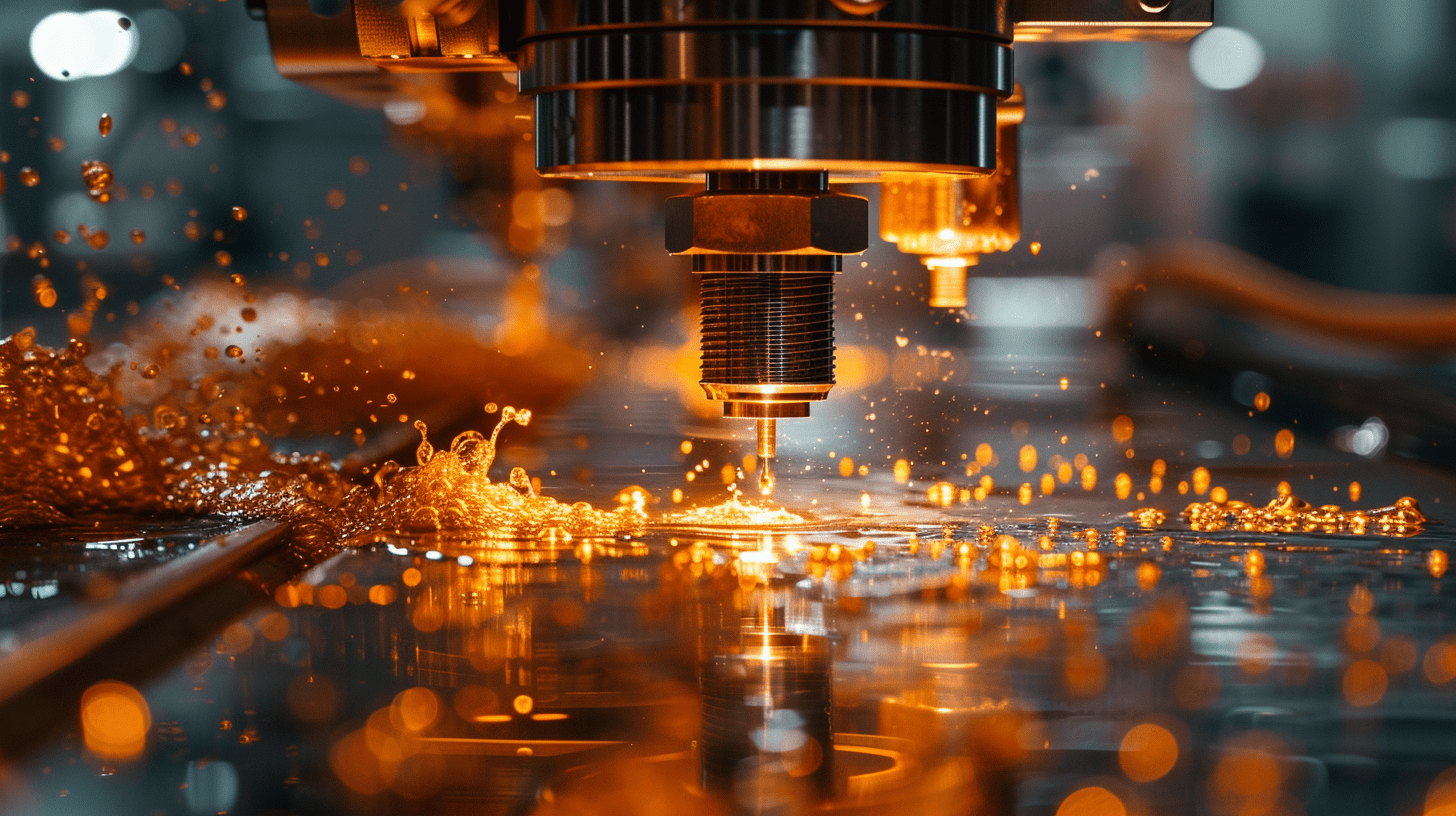

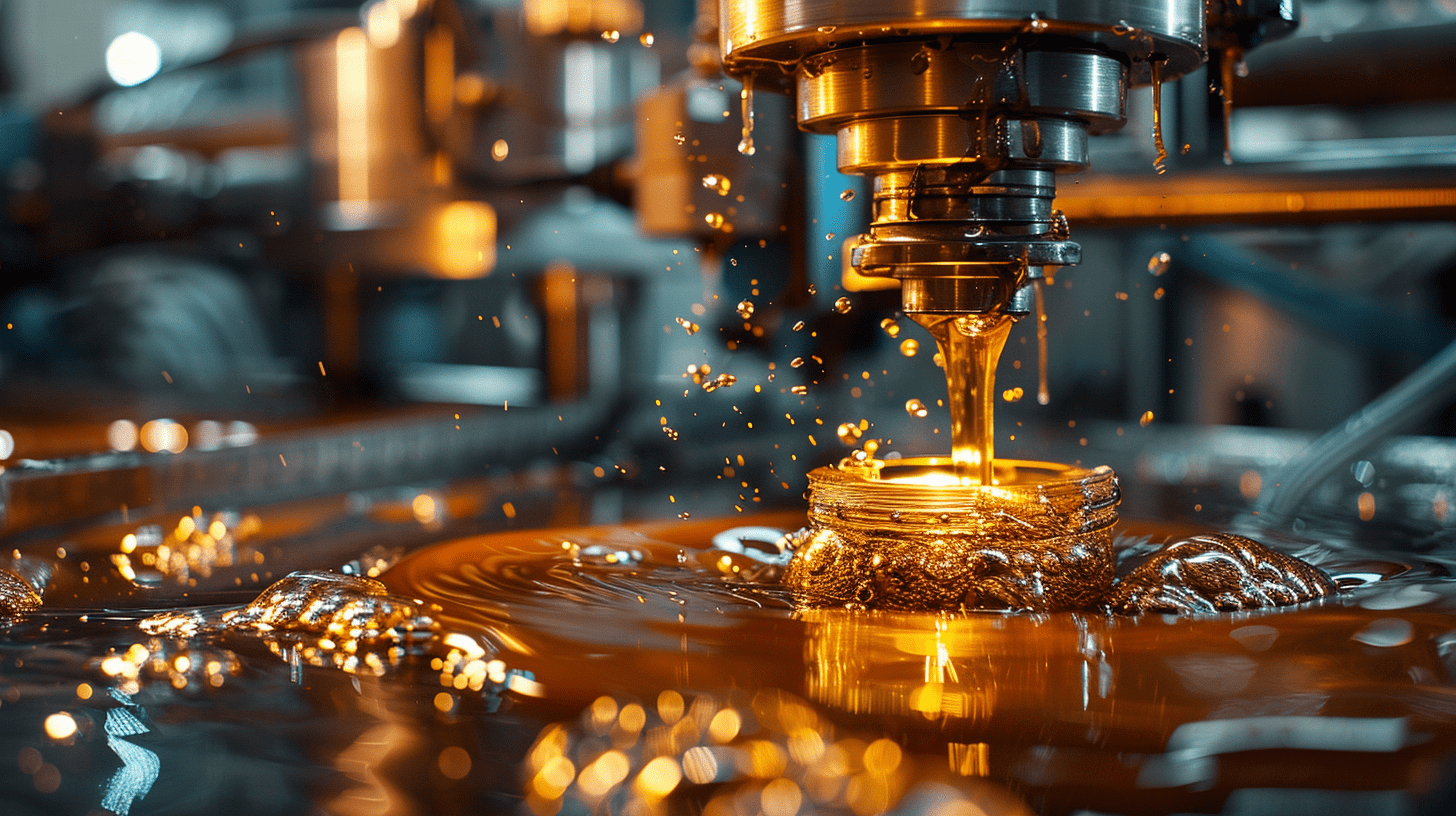

Contract manufacturing businesses adhere to stringent standards when it comes to producing quality goods at competitive prices. They often have access to specialized equipment not available elsewhere, enabling them to produce complex parts quickly while maintaining high levels of accuracy and precision throughout the production process. Furthermore, contract manufacturers count on the help of skilled employees with expertise in areas such as product development and prototyping to offer comprehensive customer support during every stage of production.

What exactly is contract manufacturing?

Industries That Leverage Contract Manufacturing

In today’s modern economy, contract manufacturing is becoming an increasingly important part of many industries’ operations. From the automotive industry to consumer goods, companies are turning to contract manufacturing for a variety of reasons and uses.

Automotive Industry

The automotive industry is one of the most prominent sectors that uses contract manufacturing. In this business model, a third-party manufacturer produces raw materials or components for a company’s finished product. Raw materials and packaging materials are usually sourced from various suppliers in order to meet competitive prices and regulatory requirements. Auto parts manufacturers benefit from working with contract manufacturers, as they can easily scale up production levels when demand increases without needing to invest in additional equipment and personnel.

Aerospace Industry

The aerospace industry relies heavily on contract manufacturing to reduce costs and save time. With this system in place, aerospace specialists can focus their resources and energy toward more strategic goals such as research and development or product innovation. Contract manufacturing also allows aerospace companies to access niche technologies from different suppliers at competitive prices. By working with multiple vendors, they can diversify their operations while still maintaining quality control over their products. As a result, aerospace companies are able to keep their budgets under control while continuing to deliver top-notch products and services.

Electronics Industry

Electronic contract manufacturers are experts in the production and assembly of electronic components, meaning they can quickly design, develop, and manufacture quality products to meet customer demand. This is especially beneficial in an ever-evolving landscape where product ideas regularly change and companies need to remain competitive while keeping up with demand.

Contract manufacturing also provides service subcontracting that allows companies to take advantage of multiple resources under one roof. This includes industrial equipment such as machining tools, welding stations, or 3D printing plants without having to invest in them separately. Moreover, contractors typically specialize in certain areas like product development or engineering, adding another level of expertise that might not be available internally.

Pharmaceuticals Industry

Contract manufacturers have become increasingly popular among drug makers due to their expertise in providing specialized types of products on demand. These partnerships allow for seamless integration between development and production operations whilst adhering to stringent safety regulations, all without compromising product quality.

Difference between manufacturing and contract manufacturing

Medical Devices Industry

For businesses operating in the medical device industry, working with a trusted contract manufacturer is essential. They have access to advanced technologies necessary for large production runs while adhering strictly to stringent safety and quality regulations.

Production facilities used by this sector are typically equipped with specialized machinery and equipment, making it an ideal choice for those that need to manufacture complex products quickly and effectively. Contract manufacturers can provide cost-effective solutions as well as reduced production time, allowing companies in this sector to focus on their core activities.

Food And Beverage Industry

Contract manufacturers provide a range of services that allow businesses to avoid the overhead costs associated with in-house production and nondisclosure agreements that protect proprietary formulas from competitors. Contract packagers are especially useful for businesses looking to expand their production capacity without investing in additional equipment or staff.

They use their own factories and systems to handle aspects of production like labeling, packaging, and product assembly. This allows food manufacturers to focus on other business operations without having to worry about day-to-day tasks involved in producing large batches of products quickly and efficiently.

Consumer Goods Industry

Using a contract manufacturer provides many benefits to companies operating within the consumer goods industry such as cost savings, improved efficiency, and better quality control. An original equipment manufacturer (OEM) may outsource the production of individual components or products to a third-party manufacturer, which can bring several advantages. For instance, raw material suppliers and aspects of manufacturing can be managed by the contract manufacturer, reducing variable costs for the OEM while also allowing them more control over their supply chain management.

Additionally, this method of outsourcing offers greater flexibility in terms of delivery times as it allows the OEM to make changes in real-time when necessary. Another major benefit of contract manufacturing within the consumer goods sector is that it covers contract packaging services. This means that businesses can save on labor costs associated with packaging items themselves..

Why should I use contract manufacturing for my business?

Industrial Equipment Industry

The industrial equipment industry is one of the most common industries that utilize contract manufacturing for their production needs. Contract manufacturers specialize in assembling components to create a product while providing labor cost savings and competitive advantages.

Working alongside contract manufacturers is a great way to lower production costs associated with expensive equipment or processes that may be too costly for the company to invest in. This way, there’s no need to put out capital investments into machinery or tools needed for certain jobs.

Plastics And Polymers Industry

Plastics and polymers involve intricate processes to produce parts that require precision for their application. Contract manufacturers have experience with these types of components and offer quality assurance services that protect customers’ investments.

Working with a reliable manufacturer streamlines the entire product life cycle from design to delivery, giving companies control over production quality while also providing access to responsible manufacturing practices like eco-friendly packaging options. This provides companies with complete control over their supply chain process while benefiting from lower cost structures than traditional house-manufacturing approaches would provide.

Contract Manufacturing Services

By outsourcing production processes, businesses are able to focus on core activities while relying on external partners to provide them with efficient services at a lower cost than if they were handling these operations themselves. Additionally, contracting experienced manufacturers offers companies access to specialized machinery, advanced manufacturing tools, and the expertise of multidisciplinary industry experts.

At Alpha Contract Manufacturing, we provide comprehensive solutions to improve the efficiency of manufacturing operations. Thanks to our technology, skillset, and expertise, we are able to handle the creation of high-quality products from initial product design to mass production. Companies can rest assured knowing that all necessary safety precautions are taken during the production process while also being able to scale up faster if needed.