Many companies turn to contract manufacturing services to streamline their production processes and deliver high-quality products to market efficiently. Whether you’re a startup with innovative product ideas or a larger company seeking cost savings and efficient production, partnering with the right contract manufacturer can be a game-changer. In this article, we explain key things you should consider to find the perfect contract manufacturing partner for your business.

The Benefits of Contract Manufacturing

Contract manufacturing is a strategic approach that enables businesses to harness a wide range of benefits, from cost efficiency and speed to market to specialized expertise and scalability. By outsourcing production to reliable contract manufacturers, companies can focus on their core strengths, mitigate risks, and gain access to cutting-edge production facilities and resources.

Cost Savings

Contract manufacturing can significantly reduce production costs for businesses. This is primarily because contract manufacturers often operate at a larger scale, benefiting from economies of scale. They can purchase raw materials in bulk at lower prices, efficiently allocate labor resources, and optimize production processes, resulting in cost savings that they can pass on to their clients.

Faster Time to Market

Contract manufacturers are experts at their craft, which means they can streamline production processes and execute them with precision. This speed and efficiency can lead to a faster time to market for your products. Accelerating the product development process can be a game-changer, especially when trying to seize market opportunities or respond to shifting consumer demands promptly.

What Is The Typical Lead Time For Contract Manufacturing Projects?

Access to Expertise and Resources

Contract manufacturers often bring extensive experience and specialized expertise to the table. They have a deep understanding of various manufacturing processes, materials, and quality control measures. This expertise can be invaluable for businesses that may not have the in-house knowledge or resources to manage complex production processes effectively.

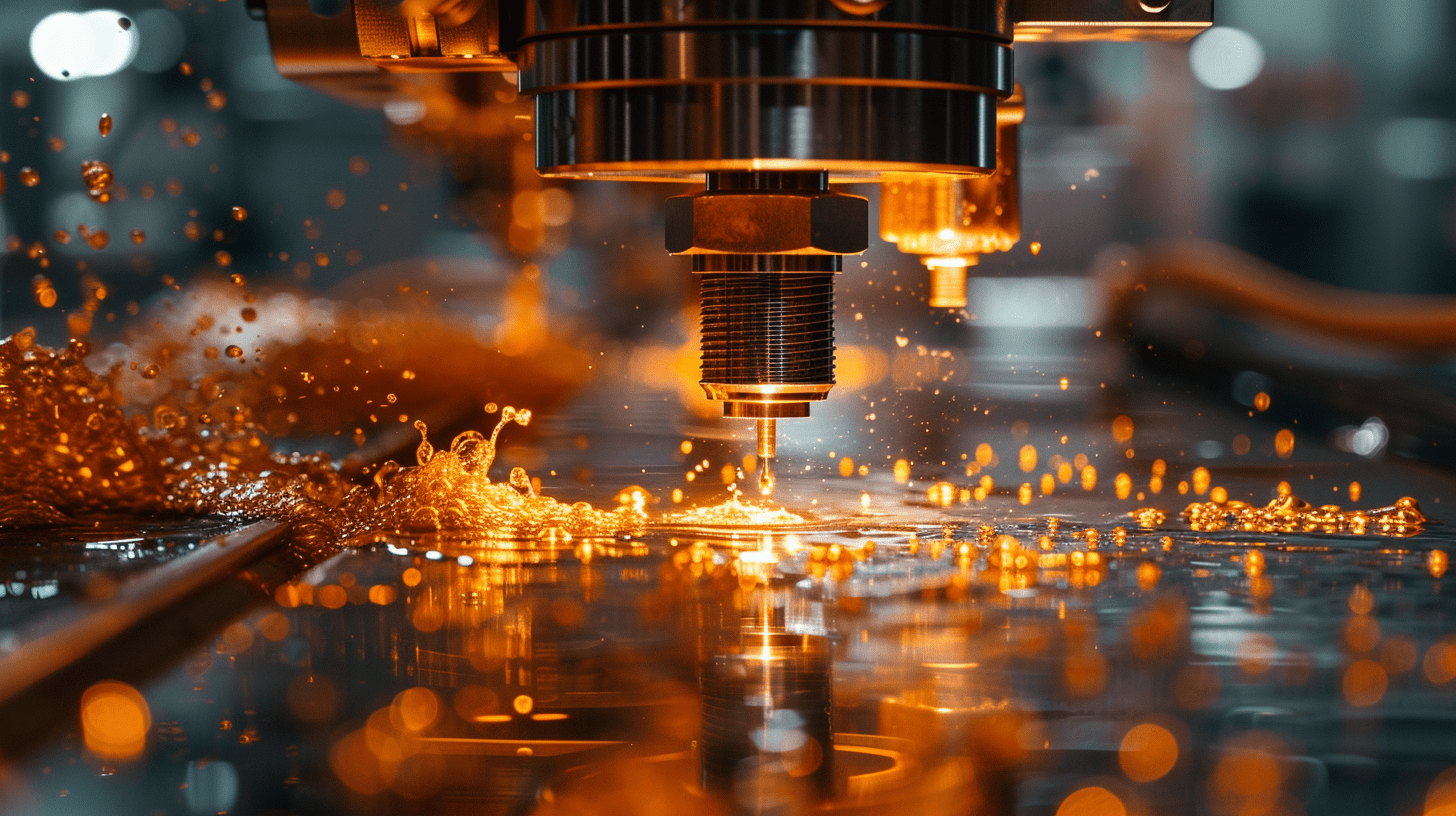

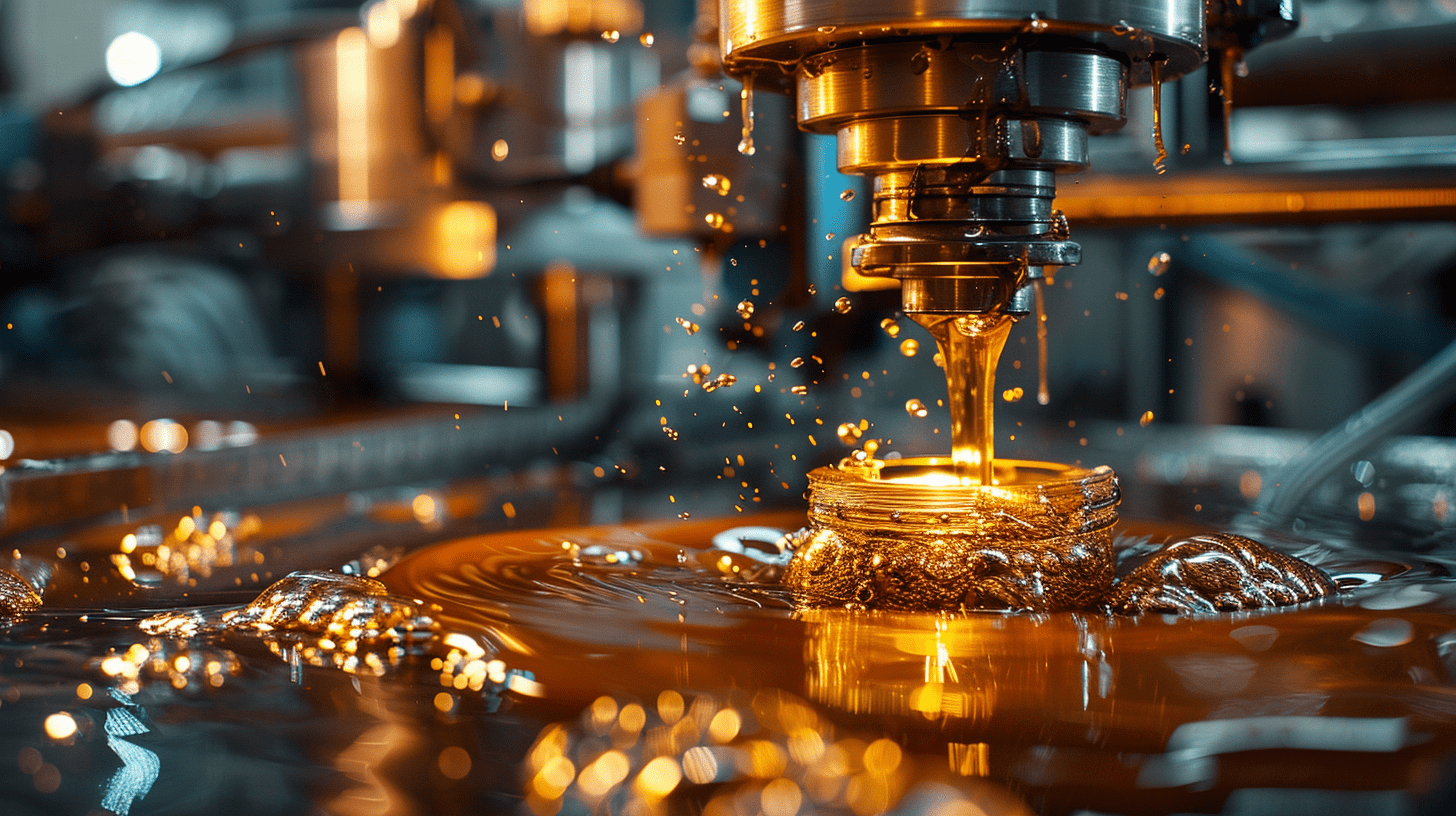

Efficient Production Facilities

Contract manufacturers invest in state-of-the-art production facilities to meet the needs of diverse clients. These are equipped with the latest technology and machinery, ensuring efficient and high-quality production. By utilizing these facilities, businesses can leverage the best available resources without the capital investment required to build and maintain production infrastructure.

Focus on Core Competencies

Contract manufacturing allows businesses to concentrate on what they do best – innovation, product design, marketing, and customer relationships. By outsourcing the production process to experts, companies can allocate their resources and attention to core competencies, ultimately enhancing their ability to innovate and grow.

Scalability

Contract manufacturing offers scalability options, allowing businesses to adjust production levels according to market demand. This flexibility is particularly valuable for companies with fluctuating production requirements. Whether you need to scale up to meet a sudden surge in demand or scale down during slower periods, contract manufacturers can adapt to your needs efficiently.

Risk Mitigation

Collaborating with experienced contract manufacturers can help mitigate risks associated with production, quality control, and compliance. These manufacturers often have established quality assurance processes, supply chain management, and regulatory compliance measures in place, reducing the likelihood of errors, delays, or compliance issues.

Global Reach

For businesses looking to expand their reach into international markets, contract manufacturing offers a pathway to tap into the global supply chain. Many contract manufacturers have a network of suppliers and distribution channels worldwide, making it easier for businesses to access new markets and take advantage of cost-effective sourcing.

Everything You Need to Know About Contract Manufacturing

6 Key Steps to Find a Contract Manufacturer

1. Define your Project Needs

Before you start your search for a contract manufacturer, it’s crucial to have a clear understanding of your project’s requirements. Consider the following aspects:

- Type of Products: Define the exact nature of the products you need to manufacture. This includes their specifications, features, and any special requirements.

- Production Processes: Determine the manufacturing processes and techniques required for your products. Are they complex or straightforward? Do they involve multiple assembly steps or materials?

- Batch Sizes: Decide on the expected production volumes and batch sizes. This will help you find a contract manufacturer capable of meeting your production demands.

- Quality Standards: Specify the quality and compliance standards your products must meet. This may include industry-specific regulations or international standards.

- Regulatory Compliance: Understand any regulatory requirements that apply to your products, especially if you are in industries like medical devices or aerospace, where compliance is critical.

- Business Goals: Align your project needs with your overarching business goals. Consider factors like market expansion, cost reduction, or innovation.

- Budget and Timeline: Define your budget constraints and the desired project timeline. This information will help you assess the financial feasibility and speed of execution for potential manufacturing partners.

2. Gather Information on Potential CMs

With your project needs clearly defined, you can begin researching potential contract manufacturing partners. Here’s how to go about it:

- Experience Level: Look for contract manufacturers with experience relevant to your industry and the type of products you are developing. Experience is often a key indicator of expertise and reliability.

- Production Capacity: Assess the capacity of the manufacturing facility. Ensure that they can handle the scale of production you require.

- Track Record: Investigate the contract manufacturer’s track record. Review their past projects and client testimonials to gauge their performance and reliability.

- Industries Served: Consider the industries the contract manufacturer has experience working with. Aligning with a manufacturer who has experience in your specific industry can be advantageous due to their familiarity with industry-specific requirements and standards.

3. Sort and Make Initial Inquiries

Once you’ve identified a list of potential contract manufacturers that match your criteria, it’s time to engage in detailed conversations. This step involves:

- Detailed Conversations: Engage in in-depth discussions about your project requirements. Communicate your expectations and ask questions to gauge their capabilities and willingness to meet your needs.

- Manufacturing Facilities: Inquire about the state of their manufacturing facilities, technology, and equipment. Ensure that their capabilities align with your production processes.

- Raw Materials and Supply Chain Management: Ask about the sources of their raw materials and their supply chain management. This is crucial for ensuring a reliable and consistent source of materials.

- Culture: Assess the manufacturer’s organizational culture. A cultural fit can be important for smooth collaboration and effective communication throughout the project.

4. Evaluate Potential CMs Qualitatively

Assess the qualitative aspects of potential contract manufacturers:

- Company Culture: Evaluate whether their values, work ethic, and approach align with your own company culture. A good cultural fit can enhance collaboration and the overall project experience.

- Compliance with International Standards: Ensure that the manufacturer adheres to relevant international standards, quality control measures, and certifications.

- Extensive Experience and Comprehensive Industry Knowledge: For complex products or projects in highly regulated industries, prioritize contract manufacturers with a deep understanding of these industries and a proven track record in compliance and quality.

5. Send Out RFQs and Compare Entities

The Request for Quotation (RFQ) stage is critical in your evaluation process. Here’s what you need to consider:

- Production Costs: Seek detailed cost breakdowns from each potential contract manufacturer. This includes manufacturing, labor, and material costs, as well as any additional fees.

- Time to Market: Evaluate their proposed timelines for production. A shorter time to market can give you a competitive advantage.

- Quality Standards: Assess the quality control measures they have in place to meet your product’s quality standards.

- Cost Savings and Efficiency Improvements: Look for innovative solutions and suggestions from potential manufacturers that could lead to cost savings or efficiency improvements in your production process.

6. Make the Final Decision

When making the final decision, consider the following factors:

- Intellectual Property Protection: Ensure that the contract manufacturer is willing to sign a non-disclosure agreement to protect your intellectual property.

- Language Barriers: Assess the level of communication and language barriers. Effective communication is crucial for a successful partnership.

- Financial Stability: Verify the financial stability of the manufacturer. A stable partner is less likely to face operational disruptions.

- Ability to Meet Project Requirements: Double-check that the chosen manufacturer can meet your project requirements, including volume, quality, and timelines.

By meticulously following these key steps, you can confidently choose a contract manufacturer that aligns with your project needs, ensuring a successful and efficient collaboration. This process not only safeguards the quality and success of your product but also establishes a foundation for a long-term, mutually beneficial partnership.

How to Protect Your Intellectual Property When Working With a Contract Manufacturer

Contract Manufacturing Services

At Alpha Contract Manufacturing Group, we lead the way in industrial subcontracting, offering one-stop solutions for manufacturing projects of all complexities. As pioneers in the Industry 4.0 movement, we foster collaboration between technology providers and manufacturers, driving the development of smart factories that will define the future of the industry. Whether you’re a small business or a multinational corporation, our services are designed to streamline operations and significantly reduce production costs.

We specialize in the following manufacturing services:

- Industrial painting services

- Machining services

- Plastic manufacturing services

- Wood processing services

- Rubber processing services

- Laser cutting services

- Metal processing services

- Industrial welding services

- Electromechanics services

- Composite manufacturing services

- Industrial automation services

- Assembly manufacturing services

Discover the limitless potential of Alpha Contract Manufacturing Group Inc. by reaching out to one of our representatives.