In today’s fast-paced and interconnected global marketplace, many businesses turn to contract manufacturing to streamline their production processes, increase efficiency, and meet growing customer demands. Contract manufacturing agreements allow companies to outsource the manufacturing of their products to specialized third-party manufacturers, enabling them to focus on core competencies and achieve cost savings.

However, before embarking on such partnerships, it is crucial for businesses to have a comprehensive understanding of the terms and conditions typically included in a contract manufacturing agreement. In this article, we explore the most common terms and conditions found in contract manufacturing agreements.

9 Terms and Conditions Commonly Found In Contract Manufacturing Agreements

1. Scope of Work

The scope of work refers to the specific tasks and responsibilities that the manufacturer will undertake in relation to the production of your products or provision of services. It outlines what materials, equipment, and facilities will be provided by both parties, as well as any additional requirements or specifications that need to be met.

A well-defined scope of work within a contract manufacturing agreement helps establish clear expectations between both parties involved. By outlining the specific tasks, materials, and responsibilities required for successful manufacturing outcomes, you can minimize potential conflicts while ensuring high-quality products or services are delivered in a timely manner.

2. Payment Terms

Well-defined payment terms play a critical role in ensuring smooth financial transactions within a contract manufacturing agreement. By clearly stating cost, outlining liabilities for late payments, including warranties of merchantability and turnaround times, as well as addressing intellectual property rights and notice requirements, both parties can confidently engage in business while minimizing risks and uncertainties associated with finances during the manufacturing process.

What are the typical costs associated with contract manufacturing?

3. Intellectual Property Rights

In a nonexclusive contract manufacturing agreement, it’s important for the contract manufacturer to understand that they’re not granted ownership or exclusive rights over the intellectual properties shared by the original equipment manufacturer (OEM). The OEM retains full ownership and control over their intellectual properties throughout the duration of the agreement. This ensures that any future use or licensing of these assets will be at the discretion of the OEM.

To safeguard against potential disputes regarding intellectual property rights, it’s essential for both parties to establish clear guidelines on how these rights will be protected. This can involve confidentiality provisions, non-disclosure agreements, and restrictions on sharing sensitive information with third parties. Additionally, a provision addressing material breach should be included in case either party fails to adhere to the agreed-upon terms regarding intellectual property protection.

How to protect your intellectual property when working with a contract manufacturer

4. Quality Control Measures

To ensure quality throughout the manufacturing process, it’s important for both parties to establish clear guidelines and expectations in their contractual agreements. These should outline specific quality control procedures, such as regular inspections and testing at different stages of production. By setting clear standards upfront, potential issues can be identified early on and rectified promptly, reducing the risk of producing subpar products.

Quality control measures encompass various stages, starting from the inspection of raw materials upon receipt all the way through the manufacturing processes until the shipment of the finished product. This is essential to guarantee the production of high-quality products and maintain customer satisfaction.

What should I consider when selecting a contract manufacturer?

5. Confidentiality and Non-Disclosure

Confidentiality protects sensitive information about the product, such as design specifications, trade secrets, and proprietary technology. Non-disclosure, on the other hand, ensures that both parties agree not to reveal confidential information to others without prior written consent. These provisions are typically included in a contract manufacturing agreement’s terms and conditions to protect the rights of both the manufacturer and the customer.

By maintaining confidentiality, the contract manufacturer can safeguard product specifications and advantages from being shared with competitors or unauthorized individuals. For customers, protecting their intellectual property is vital to prevent others from replicating their products or exploiting their market position.

To address confidentiality and non-disclosure effectively, many contract manufacturing agreements include a separate nondisclosure agreement (NDA). This standalone document outlines specific details regarding what information must be kept confidential, how long this obligation persists after the termination of the agreement and potential penalties for breaches of confidentiality.

6. Termination and Dispute Resolution

To effectively address termination and dispute resolution in your contract manufacturing arrangement, it’s important to establish clear guidelines and procedures for ending the agreement or resolving conflicts. By establishing these terms and conditions upfront, you can safeguard your rights while promoting a fair and mutually beneficial business relationship throughout the duration of the joint venture.

When drafting termination and dispute resolution clauses, it’s beneficial to seek legal advice and ensure they align with applicable laws and regulations. Consider including provisions on governing law and jurisdiction to determine which laws will apply in case of disputes. Furthermore, clearly define the consequences of termination, such as financial obligations or punitive damages if one party fails to fulfill its contractual obligations upon termination.

7. Indemnification and Liability

Indemnification is the process of compensating one party for any harm or loss they may have suffered due to the actions of the other party. Meanwhile, liability determines who is responsible for damages or losses. The inclusion of indemnification and liability clauses in a contract manufacturing agreement helps establish a fair and balanced business relationship between the manufacturer and customer.

By clearly defining each party’s responsibilities and potential risks, it reduces uncertainty and promotes trust between partners. These clauses also serve as a deterrent against negligent behavior or poor quality control practices by either party. In some cases, indemnification and liability provisions may result in additional costs for either party.

For instance, if a product defect leads to harm to consumers or damage to property, the manufacturer may be required to cover not only monetary compensation but also legal fees associated with defending against lawsuits. Similarly, customers may incur additional costs if they fail to meet agreed-upon delivery schedules outlined in the contract manufacturing agreement. It’s essential for both parties to carefully review these provisions before entering into an agreement so that they fully understand their obligations and potential consequences.

How can I ensure the quality of products produced by a contract manufacturer?

8. Delivery and Shipping

When entering into a contract manufacturing agreement, it’s crucial to discuss and agree upon delivery times. This ensures that there’s clarity on when your products will be ready for shipment and helps you plan your business operations accordingly.

Make sure you thoroughly discuss delivery and shipping concerns along with other relevant aspects of the manufacturing process with your chosen third-party manufacturer before finalizing the agreement. Taking these factors into account while negotiating can result in significant cost savings and improved efficiency in delivering products to customers.

9. Governing Law and Jurisdiction

Ensure that you fully understand the governing law and jurisdiction considerations before signing the contract, as this will protect your rights and provide a sense of security in case any legal issues arise. By thoroughly reviewing all aspects related to governing law and jurisdiction in a contract manufacturing agreement, you are safeguarding your rights. Take note of specific requirements regarding notice periods for filing claims or resolving disputes within a certain number of business days after an issue arises.

Consider seeking advice from legal professionals who specialize in international trade or contract law if dealing with agreements across borders or involving multiple jurisdictions. Remember that ignorance about these terms could have significant consequences for your business’s ability to protect its interests against creditors or government officials. Therefore, make it a priority to educate yourself and operate within the boundaries of the law to avoid unnecessary complications that may arise from misunderstandings or lack of knowledge.

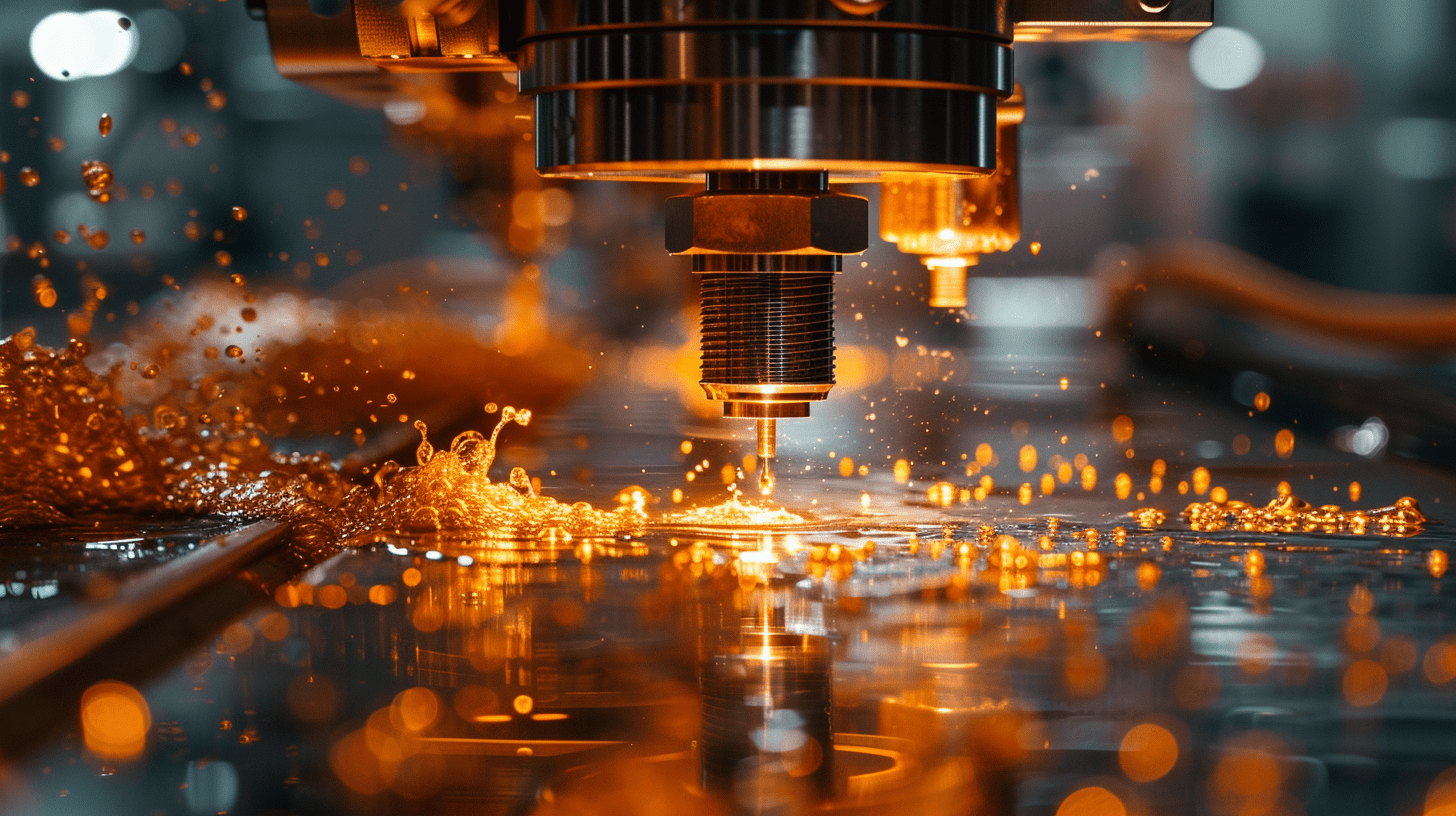

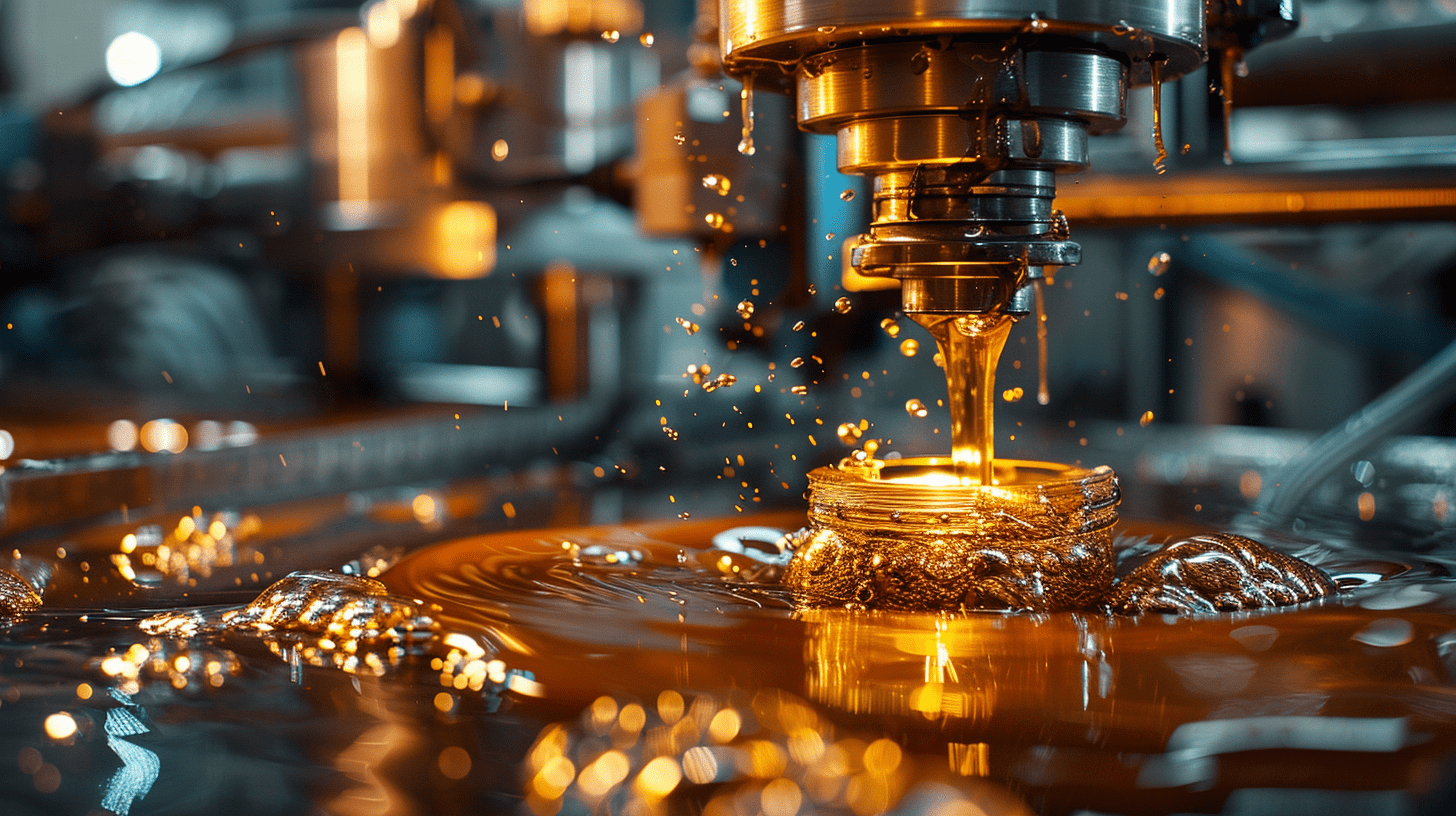

Contract Manufacturing Services

At Alpha Contract Manufacturing, we specialize in providing our business partners with high-quality products created in an innovative and time-effective environment. You can count on our experience and state-of-the-art manufacturing equipment to always deliver top-of-the-line results, regarldess of the scope and complexity of your project.