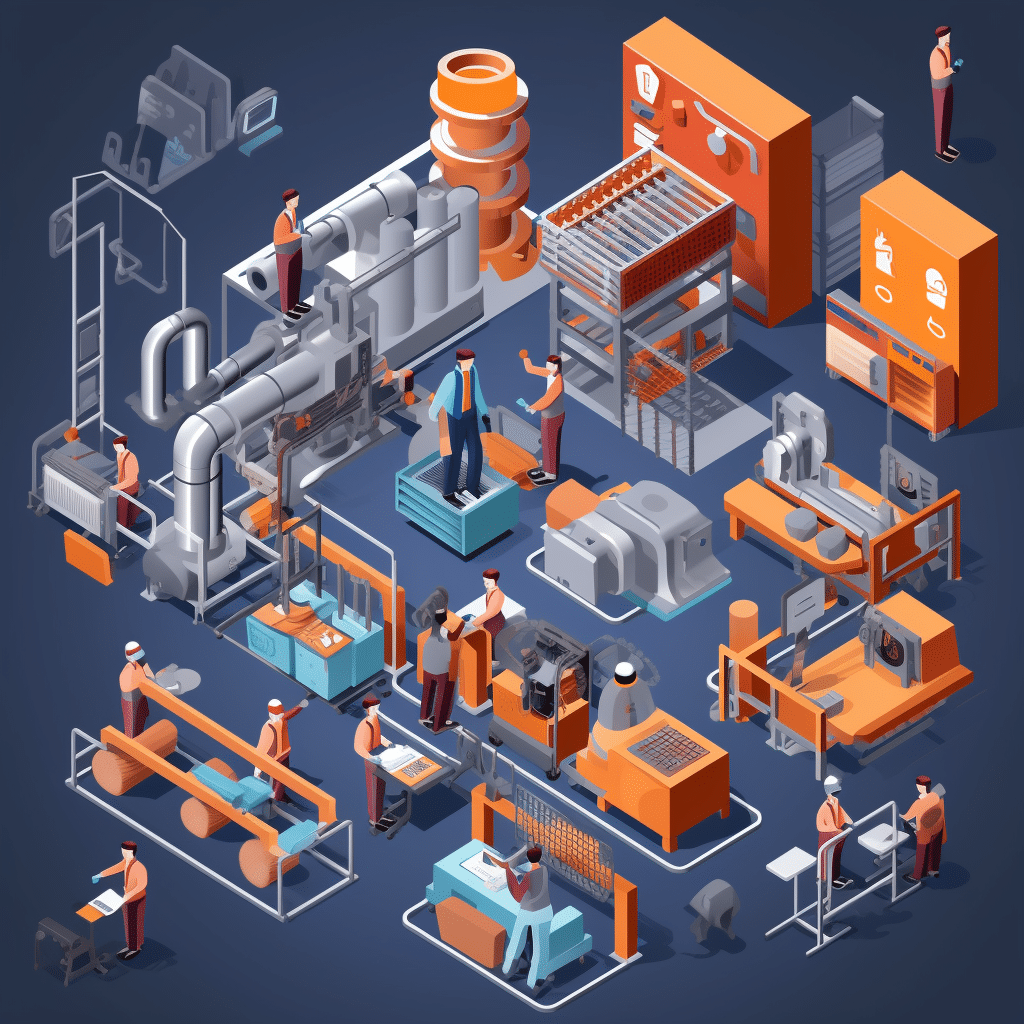

Contract manufacturing is becoming increasingly popular in the modern industrial world. It provides businesses with access to reliable and high-quality services while eliminating many of the risks associated with traditional manufacturing processes. In this article, we take an in-depth look at the various aspects of the contract manufacturing process.

What Is Contract Manufacturing?

Contract manufacturing is a form of outsourcing in which one company manufactures the products to another. This includes the acquisition of raw materials or premade parts by the contract manufacturer, who then assembles them into a high-quality product.

Contract manufacturers operate production facilities specifically designed to meet the demands of various industries. Most contract manufacturers also offer intellectual property protection services to protect clients’ designs and ideas during the entire production process. They must adhere to strict safety regulations set forth by governing bodies such as OSHA (Occupational Safety & Health Administration) and ISO (International Organization for Standardization).

There are different types of contract manufacturing available depending on the needs and specifications of an individual business. For example, some companies may require components from multiple suppliers while others may need custom design options for their specific requirements.

The contract manufacturing industry has grown exponentially over the past few years due to its cost-effectiveness and ability to provide businesses with complex product designs quickly and efficiently. Companies looking to outsource their production processes can rely on experienced contractors.

What Are The Advantages Of Contract Manufacturing?

Contract manufacturing provides businesses with flexible solutions that are tailored specifically to their needs, enabling them to scale up or down quickly depending on demand and seasonality. Companies can easily adjust operations while maintaining efficiency and quality control.

Some of the key benefits of a contract manufacturing agreement include:

- Outsourcing your product’s manufacturing to a third-party supplier can reduce labor costs while also improving supply chain management;

- Working with a contract manufacturer can reduce time to market, allowing you to launch your product much faster than if you were house-manufacturing it;

- You benefit from reduced costs without sacrificing quality. Experienced manufacturers can ensure that products consistently meet high standards in terms of performance and safety regulations.

Why would a company choose contract manufacturing instead of in-house production?

Components Of The Contract Manufacturing Process

When a company opts to use contract manufacturing services, they gain access to specialized equipment and skills which would otherwise not be available internally or at an affordable cost. This way, it can reduce costs associated with development time and labor.

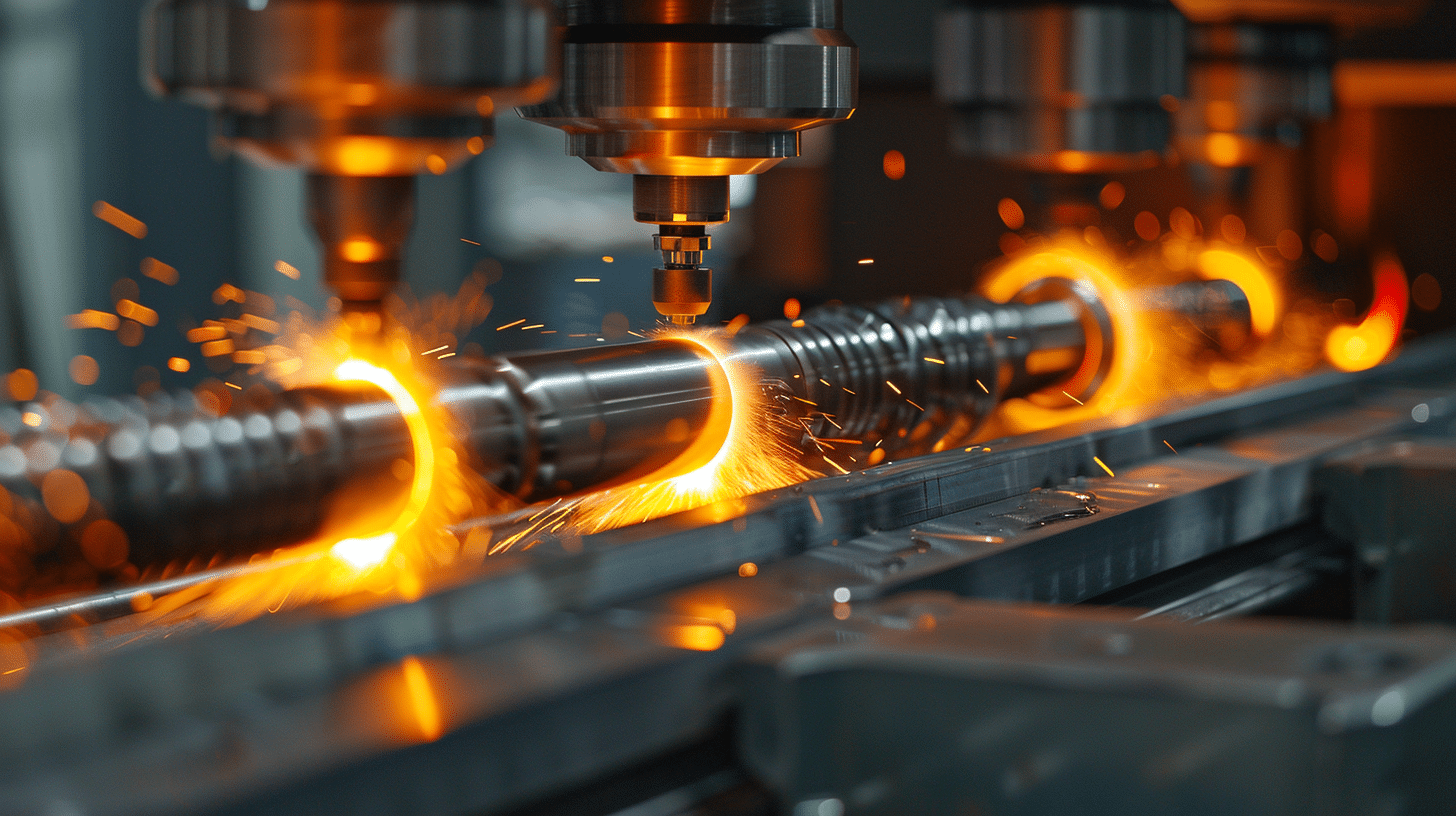

Design And Engineering

Design and engineering considerations are essential for any successful contract manufacturing process. Companies should begin with a clear idea of their product’s appearance and how it should function. This requires research, careful planning, and an understanding of engineering expertise. Depending on the complexity of the project, various specialized tools can be used to create detailed drawings or specifications. In addition, many companies have their own proprietary designs.

Once the design has been completed, it needs to be tested against specific standards to ensure quality throughout production. Quality assurance protocols are often required to be followed by manufacturers. Evaluating prototypes during this stage is also essential so modifications can be made if necessary prior to full-scale production runs. Taking these steps helps ensure that final products meet customer requirements while staying within budget limits.

Quality Assurance

Quality assurance in contract manufacturing ensures all components are made to the highest standards and there is no risk of defective parts or products being delivered to customers. Having a good understanding of design for manufacturing and knowledge of different types of materials used in production enables contract manufacturers to quickly identify potential issues before they arise, thus avoiding costly mistakes.

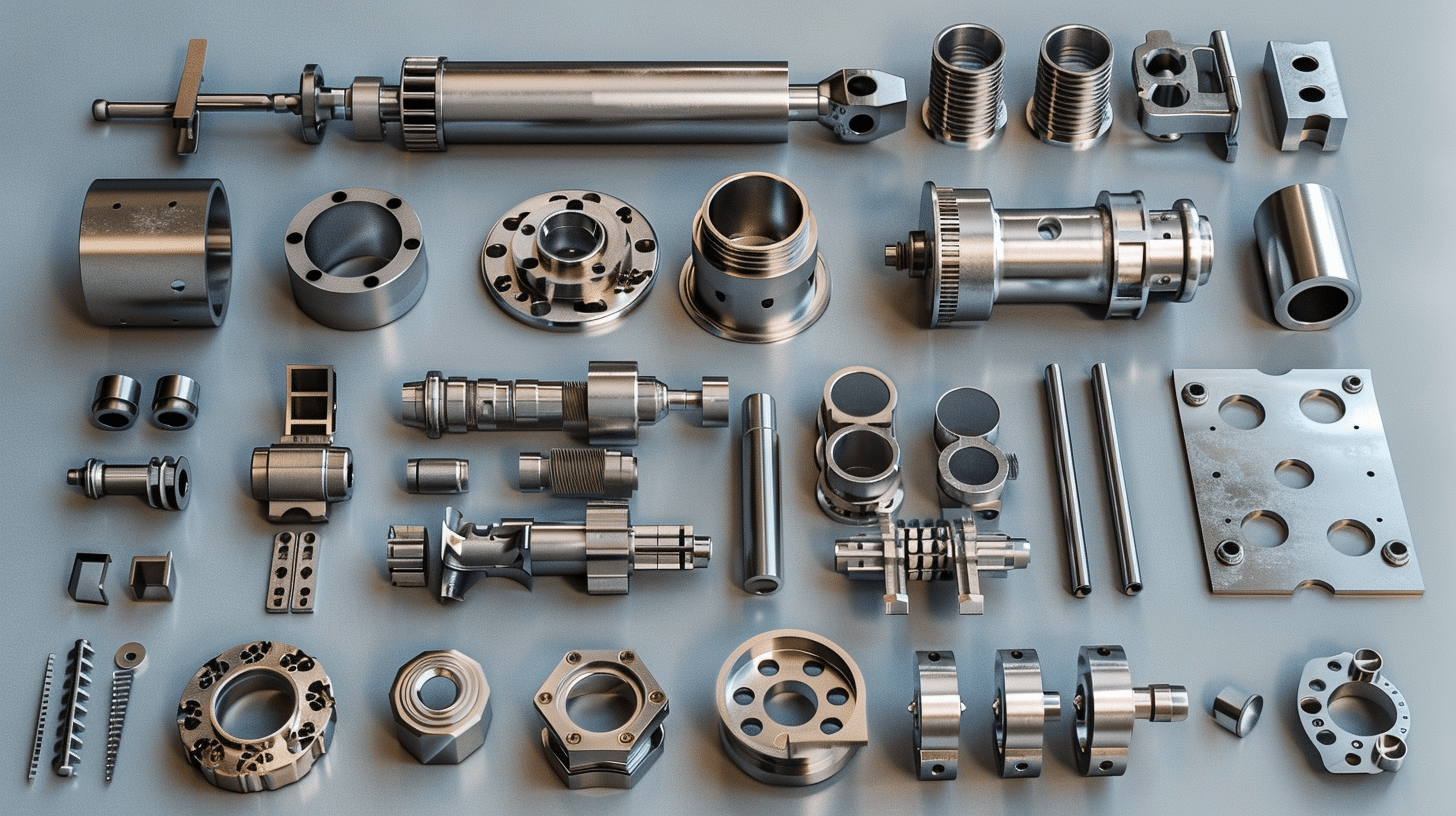

Tooling And Prototyping

The tooling involved in contract manufacturing can have a significant impact on the time taken for assembly. Prototyping is also important as it can help reduce material lead time and cost by allowing manufacturers to test out their designs before committing to producing them in bulk.

With more complex pieces requiring more specialized equipment, some projects may require longer timescales than otherwise expected due to waiting for materials or specialist machines. Bulk production using expensive equipment requires larger investments, but advances in technology such as 3D printing may help keep costs down.

Production Capacity And Capabilities

Contract manufacturers have access to a wide range of supply chain resources that allow them to provide finished products within an agreed-upon period of time. Additionally, they can source materials at competitive prices. Sometimes, contracted firms are even able to reverse engineer existing components or designs which allows for flexibility when creating new items from scratch.

Whether the customer needs only one part or thousands, contract manufacturers must be able to scale up operations accordingly without compromising on quality and price points. Customers can often save money due to reduced overhead costs associated with running their own manufacturing facilities and gaining access to specialized expertise. Partnering with a reputable contracting company is crucial if businesses want to ensure successful outcomes in terms of product development and delivery timelines.

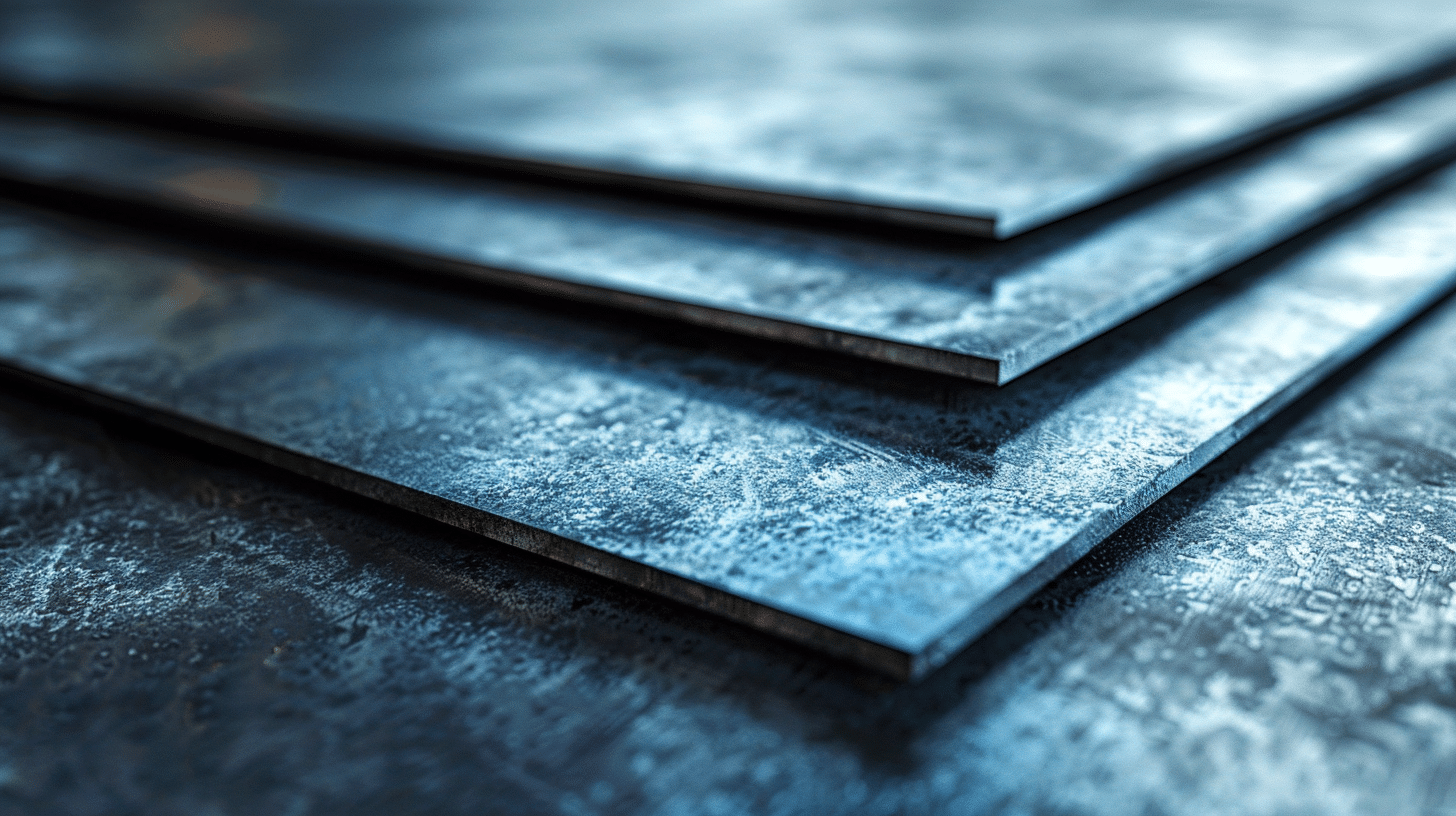

Raw Material Sourcing

For manufacturers without the internal resources or capital expenditures to build their own supply chain, partnering with a contract manufacturing business is an efficient way to acquire the materials they need to bring their products to market.

This allows for faster timelines when selecting vendors who meet quality standards, minimize risk, provide competitive pricing, and ensure continuity of source due to long-term buying agreements. It also saves time by allowing the customer to focus on product design rather than having to research each individual component needed. In addition, there is greater flexibility in terms of scalability as well as minimized overhead costs since no internal staff needs to manage vendor relationships directly.

The difference between contract manufacturing and outsourcing

Cost Management Strategies

Contract manufacturers balance the need of keeping costs competitive with producing quality products. They develop effective strategies that enable them to make sound decisions on how best to manage budgets while still ensuring satisfactory results.

Regulatory Compliance

Regulatory compliance involves understanding and adhering to laws, regulations, standards, agreements, and industry practices governing how businesses conduct their operations. Manufacturers must be aware of the international standards related to their products and the business flow between them and their customers.

Here are five key elements of regulatory compliance:

- Understanding relevant laws, regulations, codes, and industry practices;

- Ensuring compliance with intellectual property rights;

- Respecting trade secrets;

- Meeting safety and environmental requirements;

- Adopting best practice methods.

Due to their focus on the production side of doing business, contract manufacturing companies are always up to date on the latest changes to applicable rules and regulations. This allows them to remain competitive while protecting themselves against potential liability issues associated with non-compliance.

Documentation Requirements

There’s a wide variety of documentation needed throughout the entire manufacturing process. Every detail needs to be documented accurately and kept up-to-date so there’s an audit trail if questions arise about how something was produced or what went into it. Without proper paperwork, companies cannot guarantee consistent quality assurance and safety across all manufactured items. This could lead to costly recalls or other serious issues down the line.

Documentation requirements are a critical part of the contract manufacturing process. Companies producing products for others must document every step in the production, from raw materials to finished goods. This is essential to ensure that each batch of products meets customer expectations and regulatory compliance guidelines.

Post-Production Support

Post-production support covers everything from inspection and quality control to product packaging, shipment, and customer service. Depending on the business relationship between a company and a contract manufacturer, they may be responsible for providing post-production to ensure that all products meet quality standards. They also need to package the items correctly and arrange for them to be shipped on time according to the terms specified by the company they are working with.

How To Select The Right Contract Manufacturer

To ensure a successful business agreement with a third-party company, companies must consider both the level of quality and production time needed for their product as well as the cost of production and any other desired features. Companies also need to evaluate a contract manufacturer’s experience level, production capabilities, and capacity in order to guarantee that they meet or exceed expectations in terms of quality standards.

Contract Manufacturing Services

At Alpha Contract Manufacturing, we specialize in providing services that can be tailored according to the needs of each company. By leveraging our strategic relationships and robust manufacturing capabilities, companies can drastically improve their operational efficiency while gaining access to new markets without having to invest in entirely new infrastructure or personnel.

Working together, we can devise a business plan that takes the entire process into consideration, from polishing your product ideas to benefiting from economies of scale. By relying on our contract manufacturing specialists, you can focus your resources on other areas such as marketing or innovation without sacrificing product quality or delivery times.