In today’s fiercely competitive business landscape, companies face a multitude of challenges to remain agile, cost-effective, and responsive to rapidly changing market demands. One crucial decision that businesses must make is whether to pursue in-house production or opt for contract manufacturing. While both approaches have their merits, contract manufacturing has gained significant traction as a viable alternative for many organizations. In this article, we explore why some businesses prefer contract manufacturing over in-house production.

What Is Contract Manufacturing?

Contract manufacturing is a business arrangement in which a company outsources the production of its goods or components to a specialized third-party manufacturer. In this arrangement, the hiring company, often referred to as the “contracting party” or “client,” partners with a contract manufacturer, commonly known as the “contract manufacturer” or “CM,” to handle the manufacturing process on its behalf.

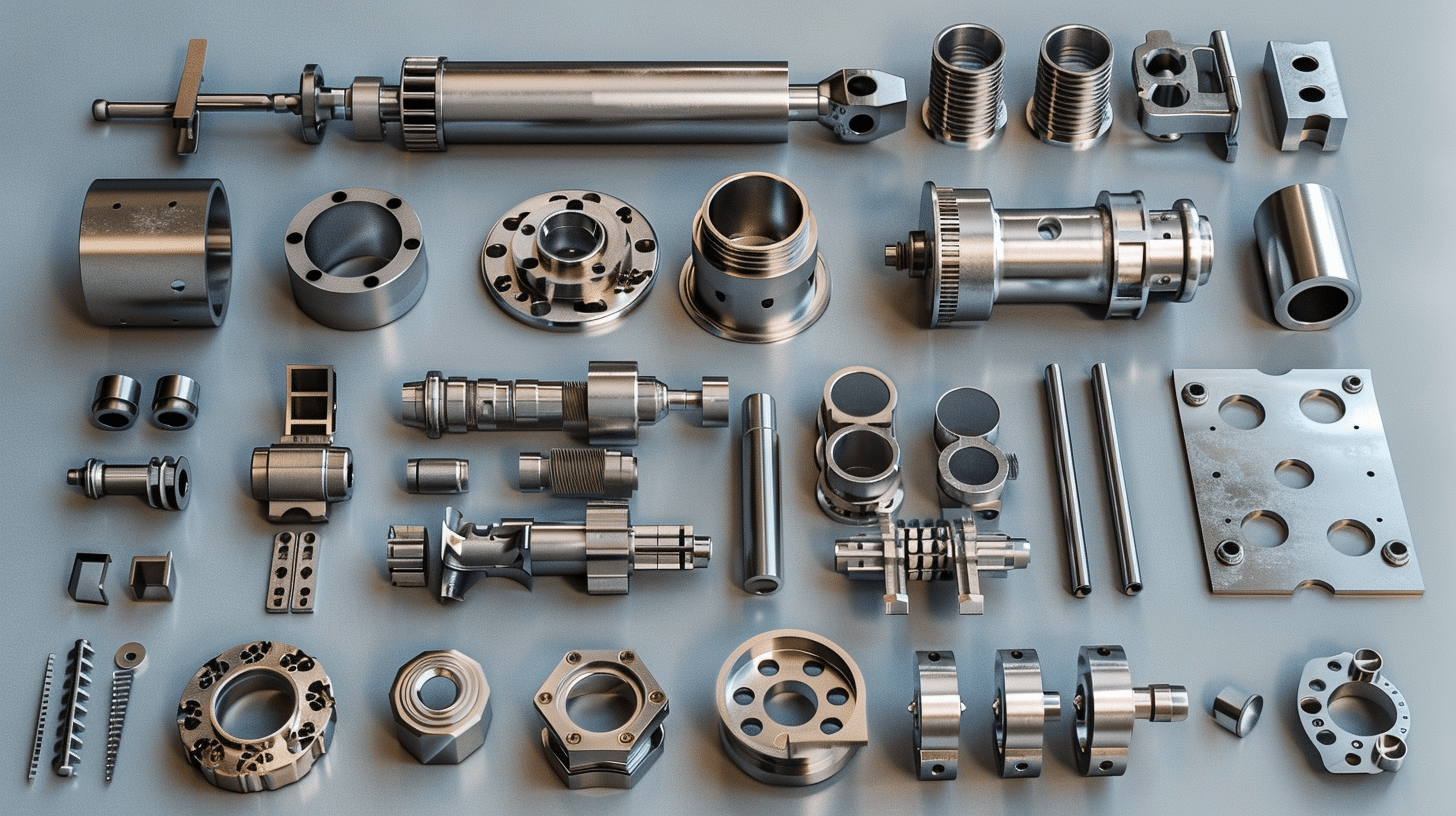

Under a contract manufacturing agreement, the contracting party provides the contract manufacturer with the specifications, designs, and requirements for the product. The contract manufacturer, equipped with the necessary resources, expertise, and production facilities, then assumes responsibility for the production, assembly, and sometimes even the packaging and distribution of the goods. The contracting party typically retains control over aspects such as product design, quality standards, intellectual property, and distribution channels.

Contract manufacturing is prevalent in various industries, including electronics, automotive, pharmaceuticals, consumer goods, and more. Companies opt for contract manufacturing for several reasons, such as cost savings, flexibility, scalability, access to specialized expertise, and reduced time to market. By leveraging the capabilities and infrastructure of the contract manufacturer, the contracting party can focus on other core competencies such as research and development, marketing, and sales.

The difference between contract manufacturing and outsourcing

What Is In-House Production?

In-house production, also known as internal manufacturing, refers to the practice of a company carrying out the production process within its own facilities using its own resources, equipment, and workforce. Instead of outsourcing the manufacturing to third-party contractors or manufacturers, the company takes full control of all stages of production, from product design and development to assembly and distribution.

In an in-house production model, the company typically invests in establishing and maintaining its own manufacturing facilities, which may include factories, production lines, machinery, and equipment tailored to its specific needs. The company also hires and manages its own workforce, including skilled laborers, technicians, engineers, and quality control personnel.

Advantages Of Contract Manufacturing

Cost Savings

Contract manufacturing can provide significant cost savings to companies that are looking for an alternative production solution. Companies may not need to invest in expensive equipment or hire additional personnel since a contract manufacturing service takes care of all aspects of the production process.

Businesses benefit from increased flexibility when it comes to production control. Contract manufacturers often offer services like inventory management and quality assurance, allowing companies to reduce operating costs as much as possible. Contract manufacturing eliminates the need to make capital investments in costly machinery and procurement costs associated with purchasing materials in large quantities.

Access To Resources And Technology

Contract manufacturing is an ideal solution for companies with limited resources and technology. An experienced and knowledgeable production management team can handle all of the heavy lifting associated with bringing complex products to market. The company will no longer have to worry about purchasing and maintaining expensive manufacturing equipment or hiring personnel with the specialized knowledge needed to operate it.

Furthermore, the cost of training employees on new machinery will also become obsolete when working with an outsourced partner. Additionally, businesses reap the rewards of higher efficiency levels due to having access to more up-to-date technologies and better quality control systems. This leads to fewer errors and improved customer satisfaction rates.

Quality Control

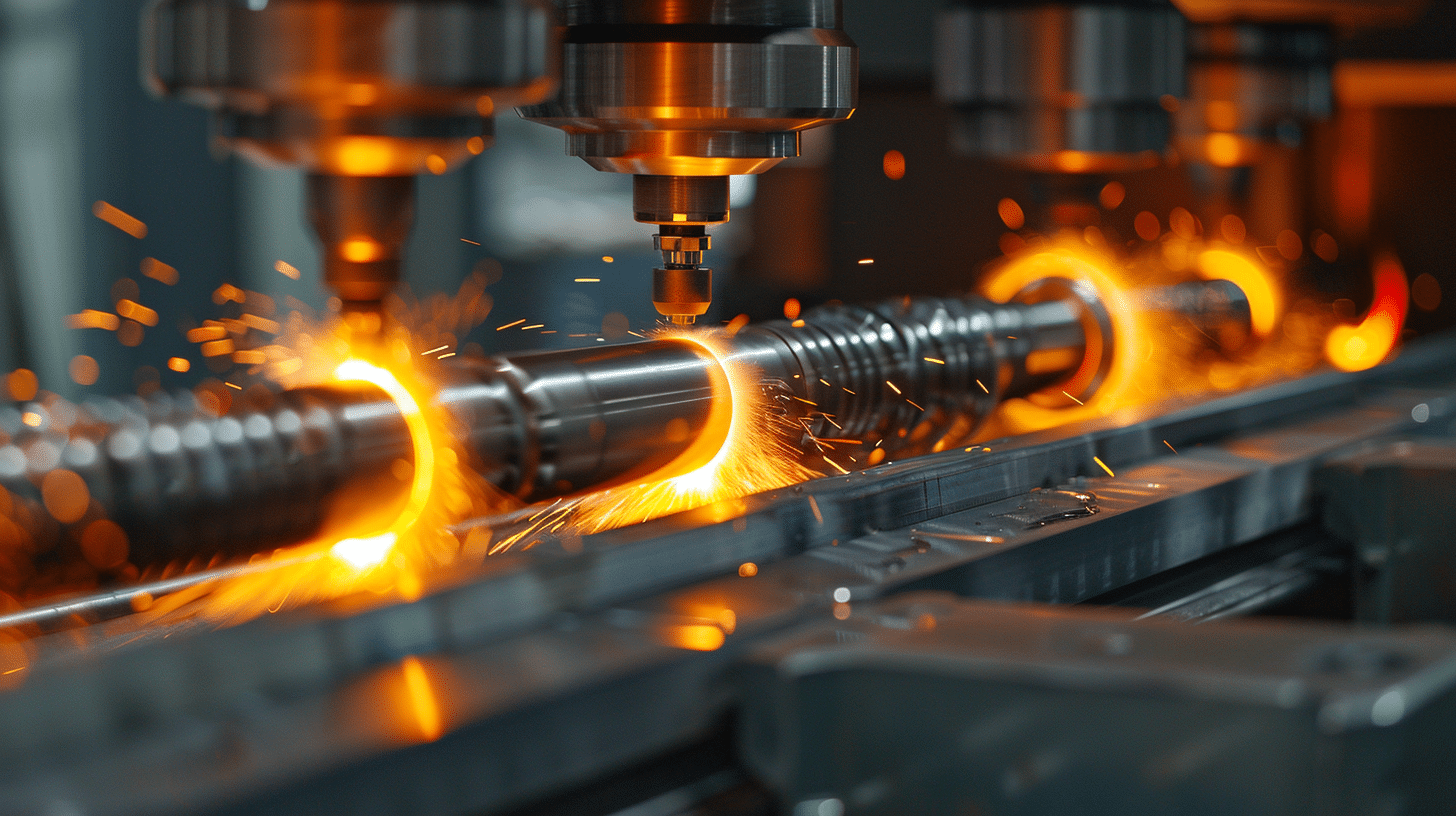

By outsourcing, companies have access to quality control procedures and the proper equipment that may be lacking in their own facility. This is especially important for the commercial production of complex products such as medical devices, as precision and accuracy are paramount.

Contract manufacturers typically operate multiple production lines with efficient production methods, allowing them to meet tight deadlines and adjust quickly to changes in product output or volume. Additionally, they often use more advanced technology than what a company could feasibly provide on its own which leads to higher quality products being produced and faster production cycles.

Flexibility And Increased Capacity

This kind of outsourcing gives businesses access to large-scale production capabilities, allowing more efficient operations and faster turnaround times. Rather than investing valuable time into producing components internally, a client company can outsource that work to an external manufacturer who specializes in those processes. Not only does this provide greater flexibility for a production cycle, but it also eliminates delays caused by machine breakdowns or waiting on certain materials.

Access To Specialized Knowledge

Contract manufacturers are experienced and knowledgeable about different types of production processes, allowing businesses to benefit from their expertise without having to build a complex internal team. This can provide many benefits including improved product quality and cost savings due to more efficient lean manufacturing techniques. Contract manufacturers are ready to leverage scalability, allowing companies to rapidly increase production capacity if needed. Businesses just need to negotiate terms and agree on timelines for delivery.

Streamlined Supply Chain

By outsourcing production tasks, companies can more easily adjust their production plan and control the quality of their product. There’s no need to worry about storage costs or extra space for inventory since the manufacturer takes care of all the logistics involved with the finished goods once they leave the factory floor.

Disadvantages Of Contract Manufacturing

Loss Of Control

Companies that choose to outsource their production lose control over certain aspects of the manufacturing process, including material selection and quality control. With in-house production, companies can leverage their own resources and team members for greater oversight during each step of the product’s development.

It’s important for companies considering contract manufacturing to consider how much control they need or want over various processes. The cost savings associated with working with external partners should also play a role when deciding between producing components internally versus using contract manufacturing services.

Language barriers

Language barriers can be an issue in contract manufacturing since the parent company may not speak the same language as their production partner. This can lead to misunderstandings or mistakes that could have been avoided with better communication between the two entities.

How to offer your industrial subcontracting services to Americans?

When To Choose Contract Manufacturing Vs. In-House Production

The decision to choose contract manufacturing or in-house production depends on factors such as cost savings, flexibility, scalability, specialized expertise, intellectual property protection, quality control, customization, and strategic differentiation. Contract manufacturing is often preferred when cost savings, flexibility, and access to specialized expertise are crucial, allowing companies to minimize capital investment, scale production rapidly, and tap into external resources.

In contrast, in-house production offers advantages such as intellectual property protection, quality control, customization, and strategic differentiation, making it suitable when companies prioritize control, confidentiality, and the ability to adapt quickly to market demands. Ultimately, the choice depends on the specific needs, resources, and objectives of each company.

Contract Manufacturing Services

Outsourcing production has many advantages such as time savings, access to specialized tools and materials, improved product quality, and better communications. Contract manufacturing should definitely be considered if your company needs help managing its growth or wants to update its current business strategy.

At Alpha Contract Manufacturing, we specialize in providing businesses with several types of contract manufacturing services, including wood processing, metal processing, mechanical welded assembly, and much more. Our services provide increased flexibility, affordability, and expertise, making them invaluable resources for companies that require high-quality goods but wish to avoid investing heavily in their internal operations.