Manufacturing and contract manufacturing often get confused with one another, but in reality, they are two very different processes. This article offers an overview of what sets these two forms of production apart from each other.

What Is Manufacturing?

Manufacturing is a term used to describe the production of goods and services. It involves creating products or semi-finished products from raw materials, using various processes, tools, machines, and labor.

The manufacturing process includes product design, development, assembly of components into finished products, testing for quality assurance, packaging for shipment and storage, and marketing activities such as pricing and promotion. Manufacturing can be done in-house or via outsourced production facilities.

What are manufacturing processes?

The manufacturing industry has a wide range of processes. These include:

- Mass production of identical items through automated processes

- Custom manufacturing to create specific, unique parts

- Contract manufacturing

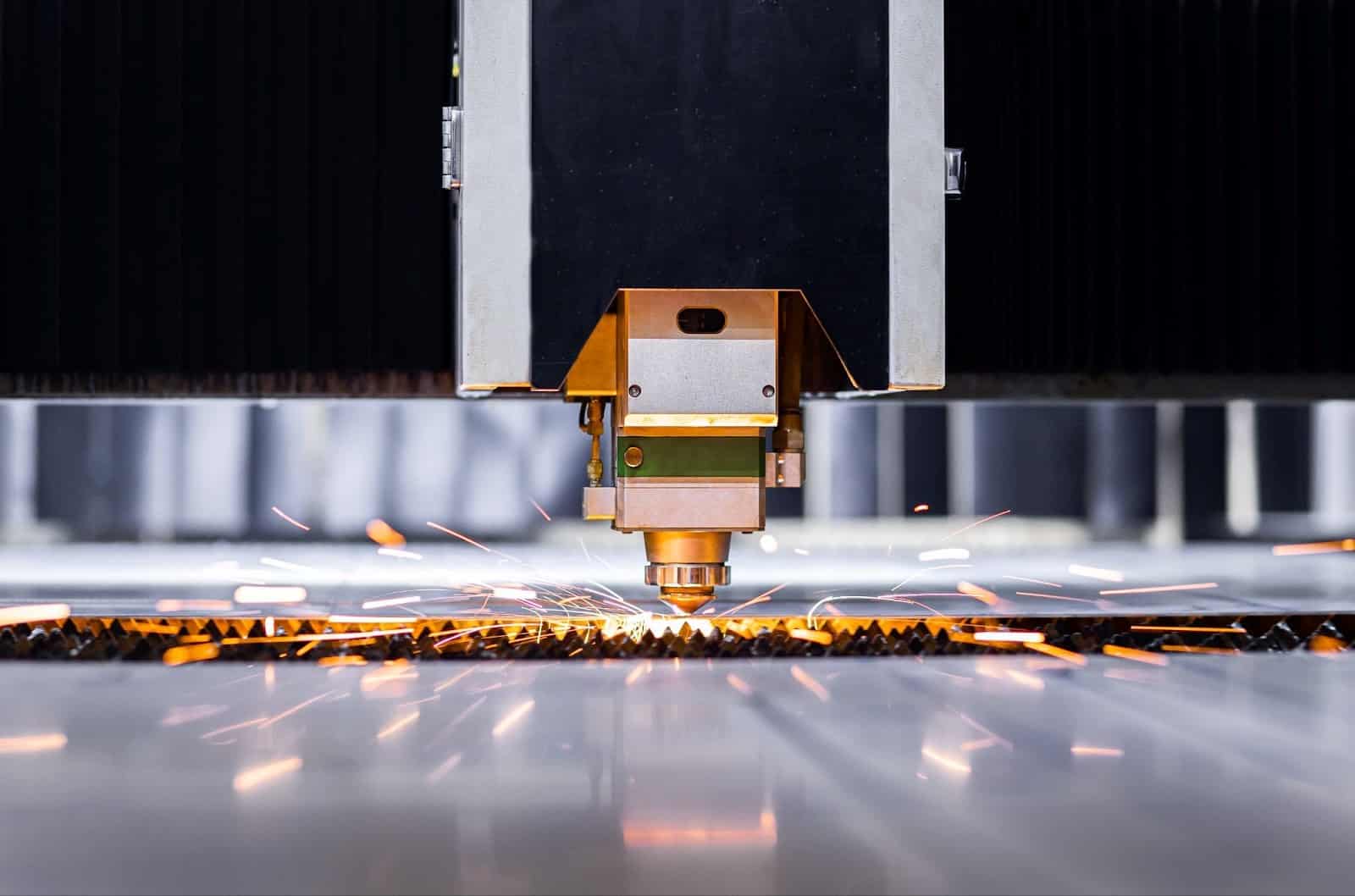

- Fabrication services that involve cutting and forming metal products according to customer specifications

- Engineering services involved with designing new products from concept to completion

- Tooling services like injection molding

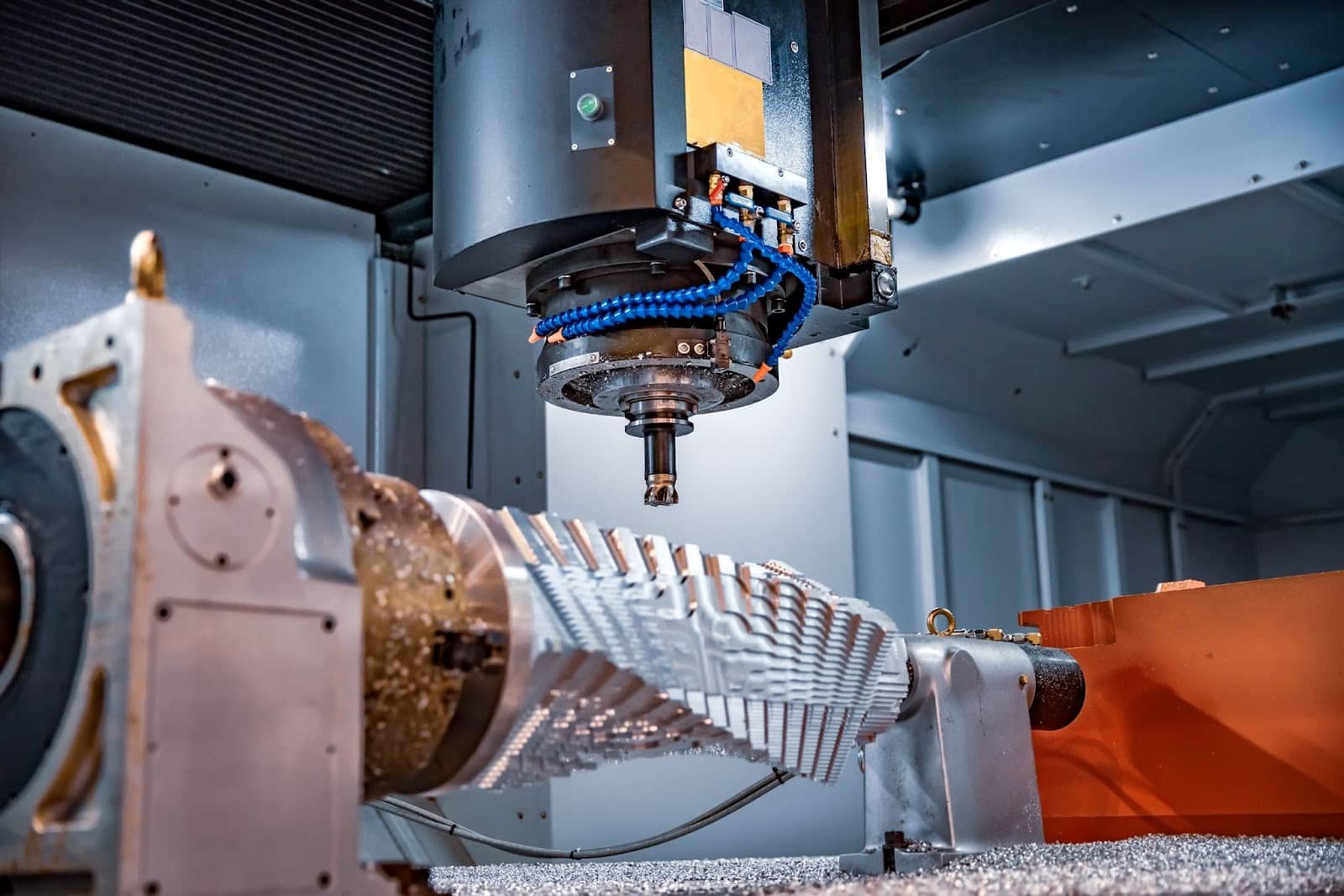

- Machining jobs based on precision tolerances required by the client

- Prototyping services that ensure accurate designs before finalizing them for market launch

- Painting and coating operations to finish off a product’s look

What affects manufacturing costs?

Manufacturing costs vary due to factors such as:

- Labor cost per unit produced

- Overhead expenses related to maintaining manufacturing facilities, including production equipment maintenance

- Acquiring additional production capacity (building extra factories)

- Material costs associated with purchasing raw materials needed to manufacture a product or service

- Energy consumption

- Wastage

- Time delays caused by unexpected issues encountered during any stage within the overall production cycle

What Is Contract Manufacturing?

Contract manufacturing is a business model in which a third party handles the manufacturing of products for private label companies. By outsourcing their production to contract manufacturers, businesses can save costs on labor, equipment, and materials while still producing high-quality products at competitive prices.

Contract manufacturing services can include everything from sourcing raw materials to packaging and shipping finished goods. The third parties involved in contract manufacturing agreements provide all of the necessary expertise, resources, and infrastructure required to manufacture a product according to specific requirements.

Private label manufacturers also benefit from having access to additional capabilities and flexibility in terms of customization options. This type of agreement allows them to quickly scale up production when needed without incurring extra costs associated with setting up their own factory or hiring an outside manufacturer.

What exactly is contract manufacturing?

Similarities Between Manufacturing And Contract Manufacturing

Manufacturing and contract manufacturing both involve the creation of goods. Likewise, both types of production require quality materials for successful product creation and efficient supply chain management to acquire them.

Differences Between Manufacturing And Contract Manufacturing

When comparing manufacturing and contract manufacturing, there are some clear differences to consider:

- Raw materials: Manufacturing companies typically use their own proprietary raw materials for production, while contract manufacturers rely on solid supplier relationships for these resources. A type of contract manufacturing known as toll manufacturing produces parts or components from supplied raw materials.

- Finished products: Manufacturing often results in products owned by the company producing them. In contract manufacturing, the ownership usually resides with the customer that placed the order.

- Labor force: When it comes to who actually performs the work, traditional manufacturers employ their own workers directly but contractors may outsource tasks to an external third-party company.

- Cost savings: Capital investment is typically lower in contract manufacturing due to less overhead costs associated with the process. This means that businesses can benefit from a reduced cost of capital when utilizing contract manufacturers instead of handling production themselves.

In terms of advantages and disadvantages related to each approach, traditional manufacturing offers more control over processes because it provides greater oversight into the design and development phases. In contrast, contract manufacturers can provide cost savings due to economies of scale achieved through working with multiple customers at once.

Advantages Of Manufacturing

The advantages associated with having a dedicated manufacturing facility include the ability to control product development and innovation, maintain quality assurance throughout the entire production cycle, and provide private-label products directly to consumers.

Having access to sophisticated manufacturing equipment also allows companies to take advantage of economies of scale, whereby they produce bulk quantities at lower costs per unit. However one must shell out a considerable amount of money before being able to shell out complete products through private manufacturing.

When considering the best option for their own business needs, organizations need to evaluate both internal and external factors including budgeting requirements, time constraints, resources available, level of expertise required, etc. While there are benefits to doing it yourself versus outsourcing some or all parts of your project’s production needs, ultimately the choice will depend on what works best for each individual business scenario.

Advantages Of Contract Manufacturing

There are several benefits to using contract manufacturing over traditional methods. Contract manufacturers often have access to better resources than what may be available internally, such as specialized equipment or higher-quality materials for production. Additionally, they provide expertise in areas where you may lack knowledge or experience, such as quality control measures during the assembly process.

Contract manufacturing can be a great solution for businesses looking to outsource production and focus on other aspects of their operations. These companies take on much of the burden when it comes to acquiring needed materials and components for your product, freeing up internal resources from tedious procurement tasks so that more time and energy can be devoted to other aspects of your operations.

Another key benefit of working with a contract manufacturer is that they are able to provide toll manufacturing capabilities. Since these companies specialize in mass production, they are often more efficient at producing large numbers of parts quickly than an individual company would be. This makes them ideal partners when trying to meet tight deadlines or fulfill large orders.

Contract manufacturers also offer private label opportunities that allow customers to have a custom-made product branded under their name. They may even provide additional post-manufacturing services such as packaging or shipping so customers don’t have to worry about managing those tasks themselves. All in all, partnering with contract companies offers numerous advantages over traditional methods of production.

Why should I use contract manufacturing for my business?

Which One Is Right For Me?

If you’re wondering which of these two manufacturing strategies is the right choice for your company, there are several important factors to consider. Here’s what you should take into account:

- Quality products: Many companies prefer to manufacture their own products in-house to have full control over quality standards. However, contracting out production can also yield high-quality results thanks to qualified professionals tasked with handling monitoring duties.

- Getting your product to market: While manufacturing in-house gives you control over how quickly your product makes it to customers, contract manufacturers already have a solid infrastructure for rapid product delivery.

- Degree of control: Traditional manufacturing gives businesses complete autonomy when it comes to designing and producing their items. In contrast, contract manufacturing allows companies to rest easy knowing all procedures involved in the realization of their products will be handled by manufacturing experts.

If you want total control over quality assurance and production timelines, then in-house production may be right for you. However, if you wish to leverage a wider range of advantages like low overhead costs, consistent product quality, extra production capabilities, and a well-developed supply chain network, then contract manufacturing is the way to go.

Contract Manufacturing Services

Contract manufacturing offers numerous advantages over traditional methods of item production such as lower overhead costs, faster turnaround times, better quality control measures, reduced waste/scrap percentages, increased efficiency through automation, and improved customer service due to shorter lead times.

At Alpha Contract, we’re ready to deploy a wide range of contract manufacturing options, empowering your business to overhaul production and take advantage of economies of scale. By working with us, companies can save on equipment and labor costs while still maintaining control of their supply chain. Thanks to our experience in different types of contract manufacturing services, we enable businesses to benefit from lower distribution costs, faster production planning, access to advanced manufacturing tools, and much more.